Marking head and marking device using the same

A scribing head and scribing groove technology, which is used in fine working devices, glass cutting devices, glass manufacturing equipment, etc., can solve problems such as scribing groove bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] (Embodiment 1)

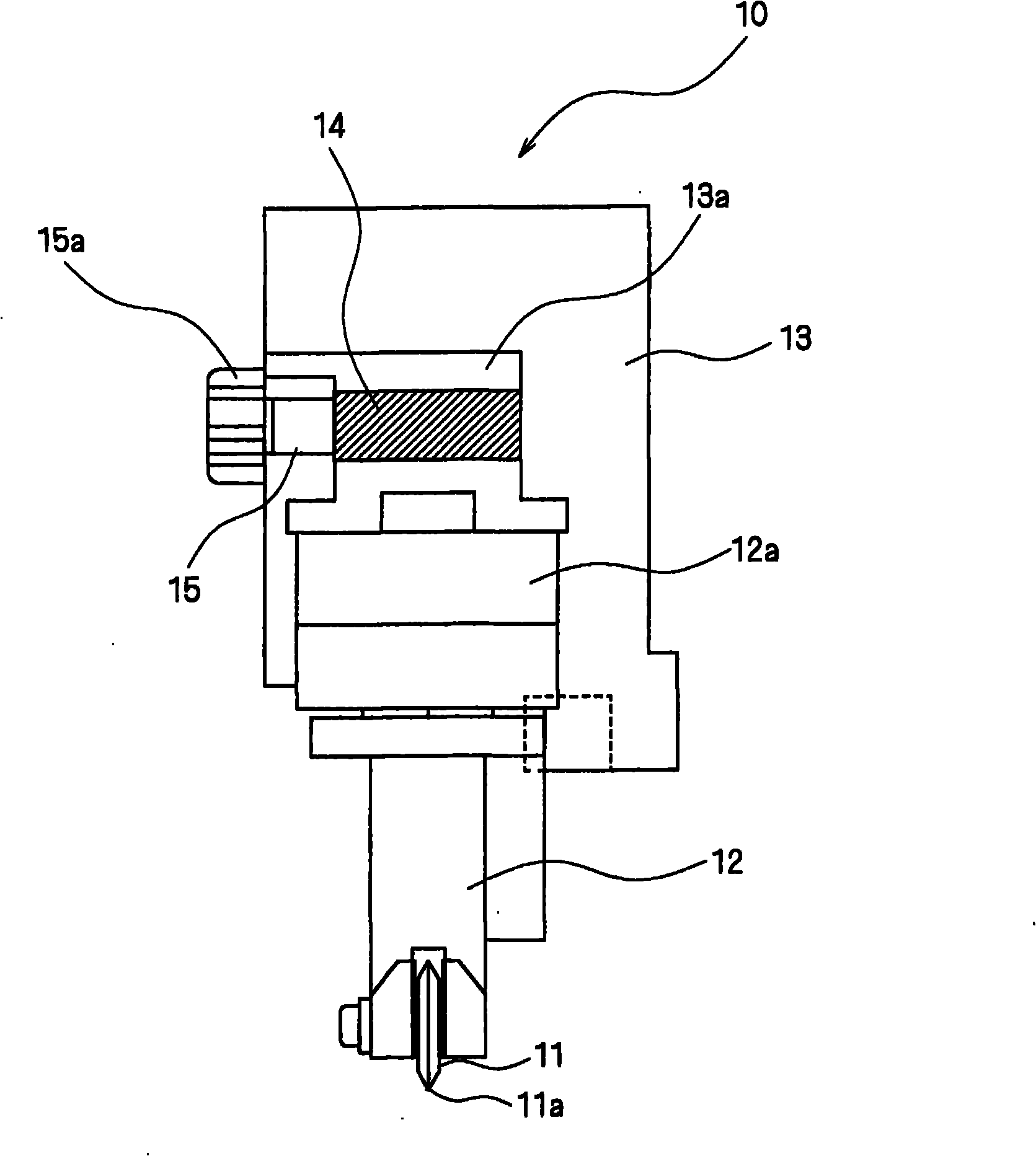

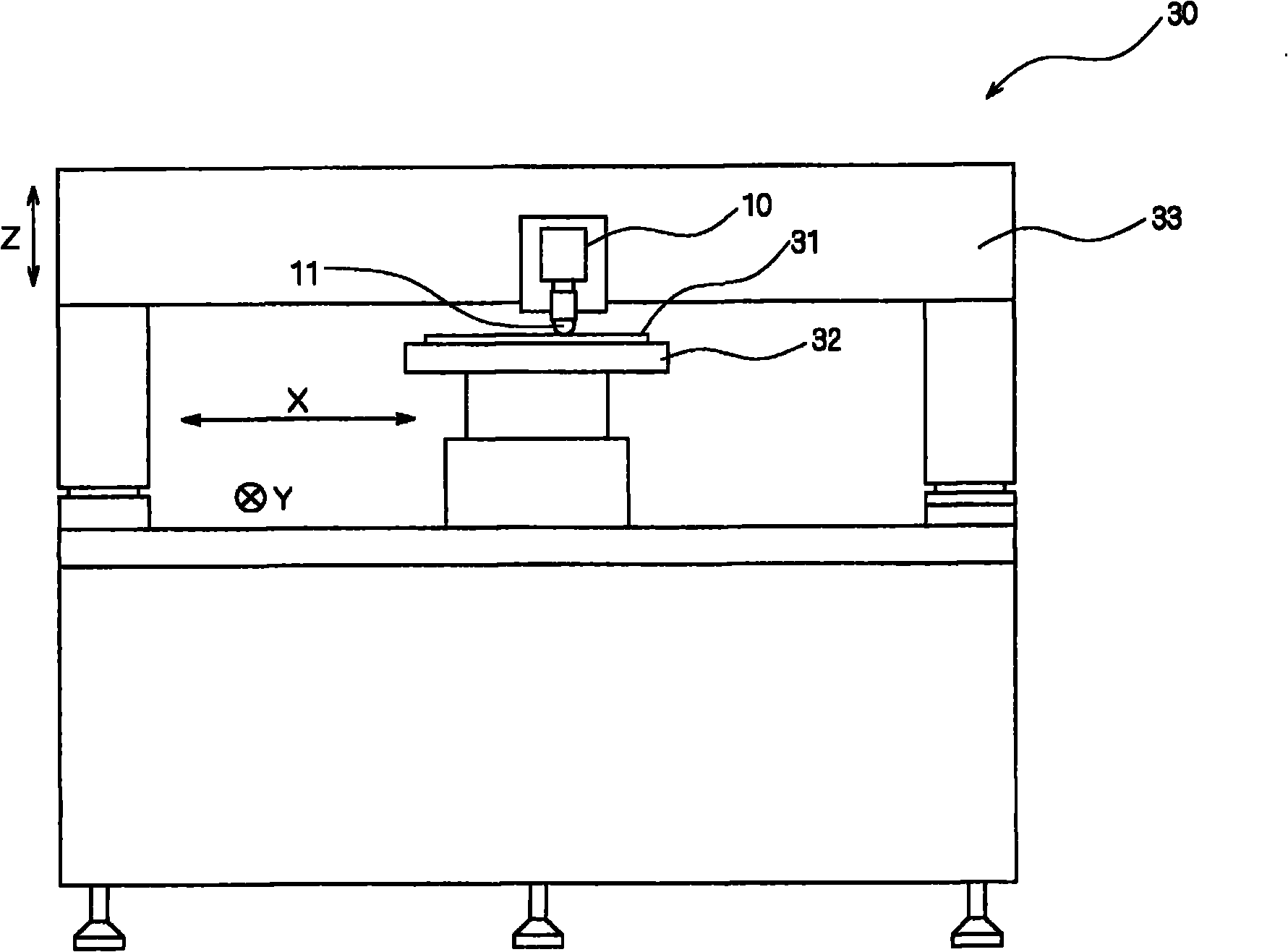

[0065] figure 2 A side view showing a schematic configuration of a scribing head according to Embodiment 1 of the present invention. also, image 3 A front view of a scribing device using the scribing head according to Embodiment 1 of the present invention.

[0066] First, for figure 2 Description of the scribing device for the scribing head shown. Such as image 3 As shown, the scribing device 30 is provided with a support table 32 that supports a brittle material 31 and can be moved. Support table 32 can be in X direction (to image 3 The left and right direction of the paper surface) and the Y direction (to image 3 The vertical direction of the paper surface) moves the brittle material 31 . Moreover, the scribing device 30 is provided with the scribing head 10 on the bridge part 33 which straddles the support table 32 in the X direction. The scribe head 10 is in the Z direction of the brittle material 31 forming the scribe groove (for i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com