Method for decorating television shell

A technology for TV casings and injection molded parts, applied in the field of technology, can solve the problems of monotonous logo color, poor visual effect and texture, etc., and achieve the effects of monotonous color, ever-changing colors, and low-grade appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] According to the requirements of the product, the present invention can manufacture a common injection mold and a high-gloss injection mold respectively, and inject ordinary injection molded parts and high-gloss, colorless and transparent injection molded parts respectively, and then perform hot stamping on the injection molded parts according to the needs of the product. , Injection coloring and other processes. The purpose of making the appearance of injection molded parts have good visual effects, good texture and rich colors. The specific decoration steps of the TV casing are as follows:

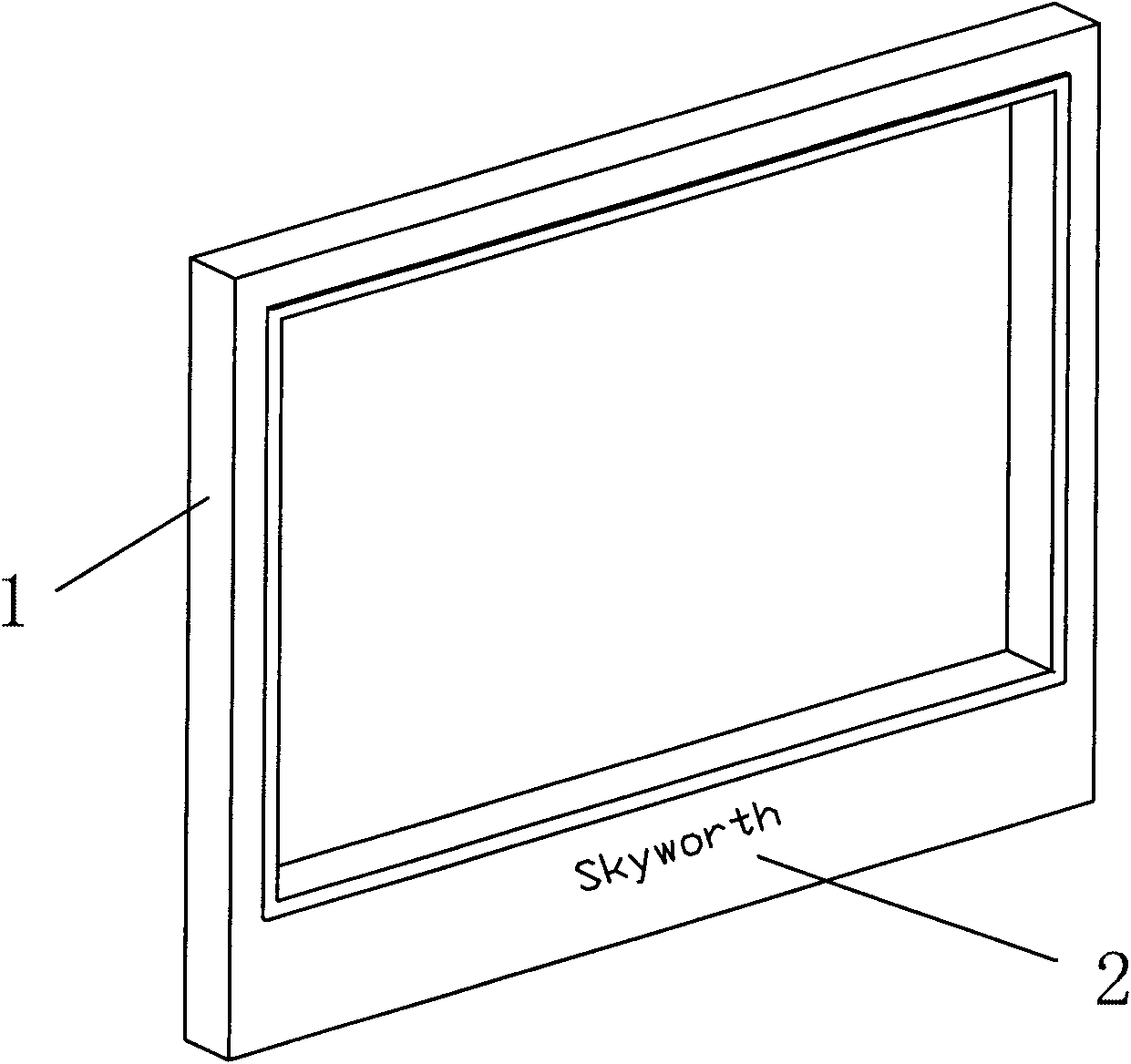

[0020] Step 1: Through the selected injection molding equipment and injection mold, ordinary injection molding parts and high-gloss, colorless and transparent TV plastic casings can be injection molded respectively. Please refer to figure 1 .

[0021] Step 2: Transport the plastic casing of the TV to the hot stamping station through the automatic assembly line, and use special f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com