Quick detachable combined cover cap capable of bearing stress

A flap and hinge technology, applied in aircraft parts, ground devices, aircraft accessories, etc., can solve problems such as affecting maintainability, increasing structural weight, affecting access, etc., to ensure structural strength, easy installation and maintenance, The effect of the maintainability guarantee

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

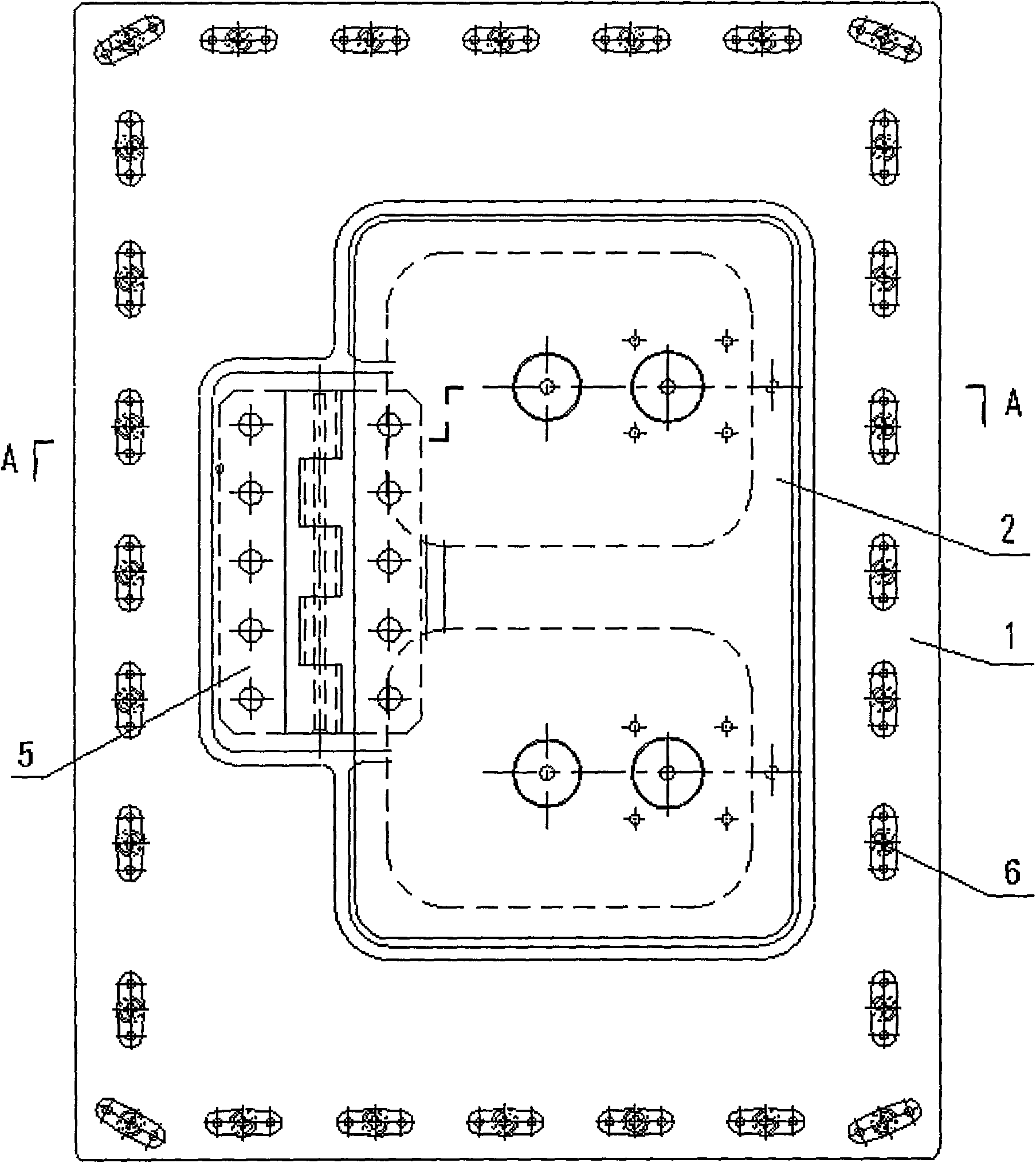

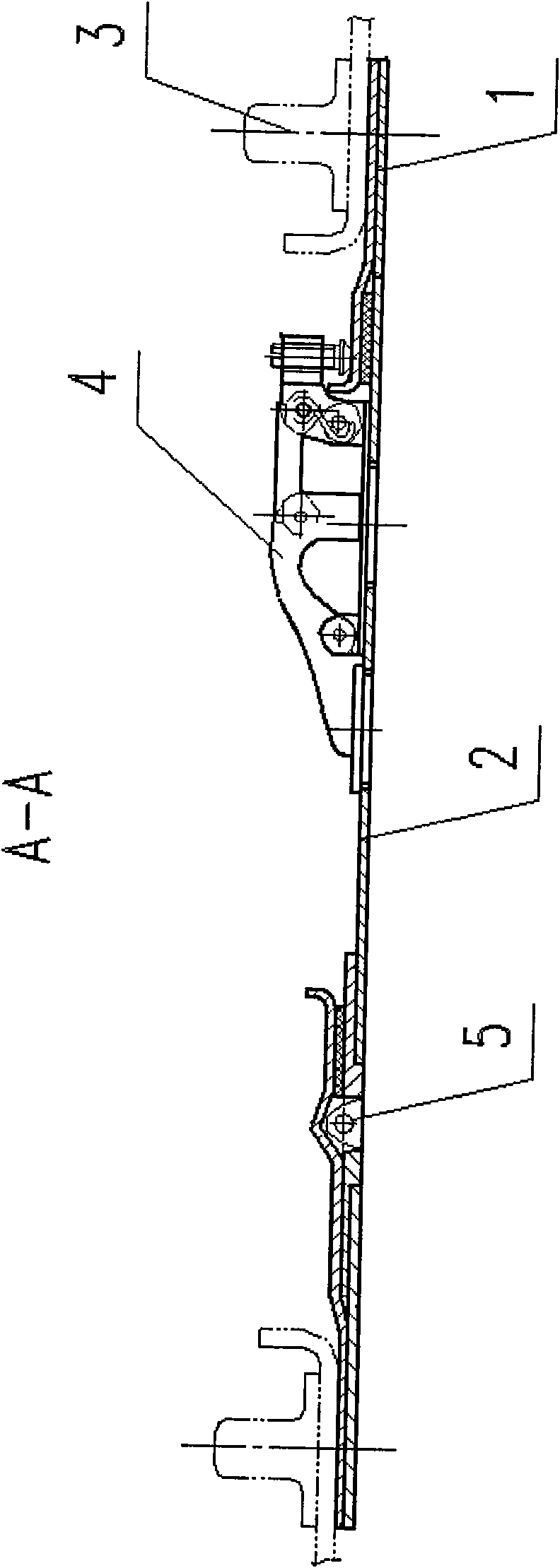

[0008] Below in conjunction with accompanying drawing, the present invention will be further described, see attached drawing figure 1 , 2 , a load-bearing quick-release combination cover, composed of a normal-stress-bearing cover 1 and a quick-release cover 2, the outer edge of the normal-stress-bearing cover 1 is connected to the aircraft skin through a supporting plate nut 3 and a bolt 6, and the bearing The normal stress cover 1 is provided with a rectangular, circular, square or elliptical opening, which is characterized in that the opening in the normal stress cover 1 is equipped with a quick release cover 2, and the shape of the quick release cover 2 is the same as The shape of the opening provided in the normal stress opening cover 1 matches, and is connected with the normal stress opening cover 1 through the hinge 5 and the force lock 4, so that the quick release cover 2 covers the inner opening of the normal stress opening cover 1 .

[0009] The load-bearing quick-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com