Composite covered yarn, and manufacturing method and use thereof

A technology of covering yarn and filter material, applied in the direction of separation method, chemical instrument and method, yarn, etc., to achieve the effect of maintaining original strength, low cost, improving performance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

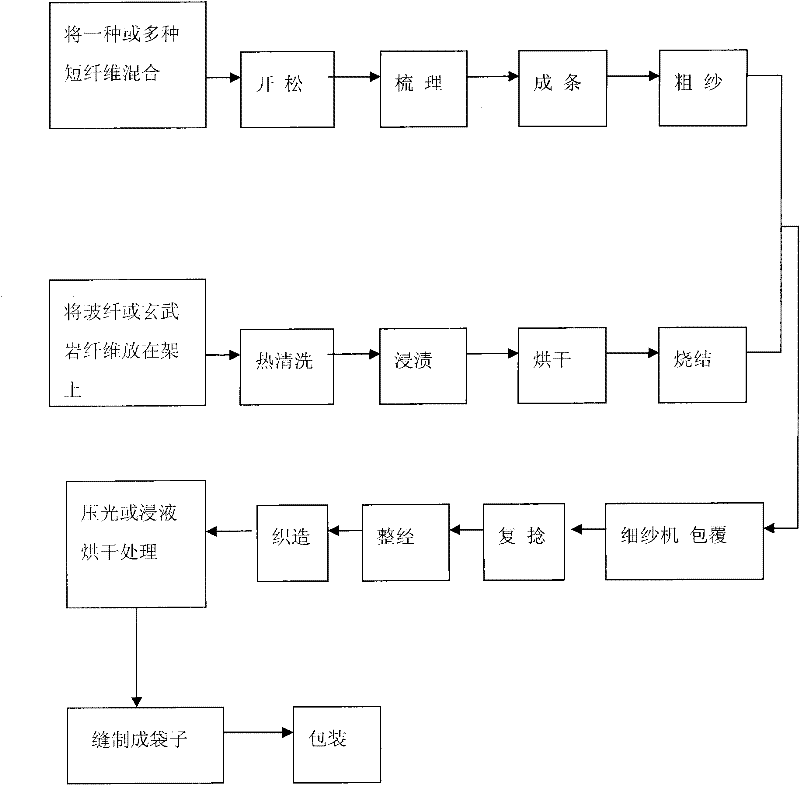

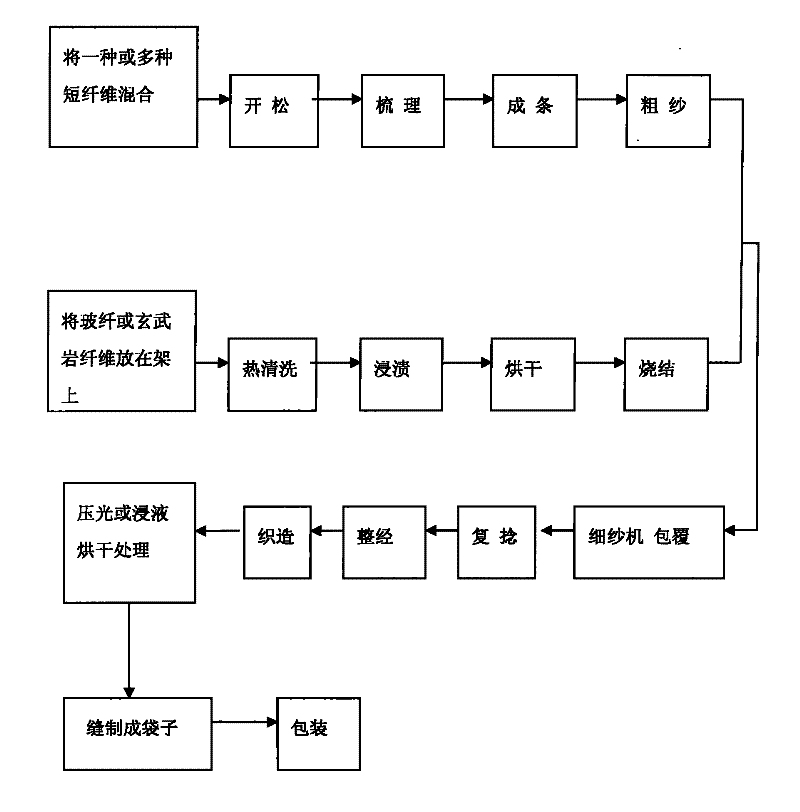

Method used

Image

Examples

Embodiment Construction

[0034] According to the performance of various fibers, choose different collocations to meet the needs of various industries or working conditions. According to various typical matching methods in practical applications of filter materials made of composite covered yarns:

[0035] (1) For the dust removal filter material of the coal-fired boiler in the power plant, glass fiber is treated with PTFE as the reinforcement rib of the inner layer, and +PPS short fiber is used as the covering yarn.

[0036] (2) Dust removal filter material for waste incineration industry, made of glass fiber yarn or basalt yarn or blended yarn of glass fiber and metal wire or blended yarn of basalt fiber and metal wire or blended yarn of glass fiber and PTFE long fiber For reinforcing ribs, use PTFE or PPS or aramid staple fiber or blended fiber of P84 or above fiber as covering yarn.

[0037] (3) Dust removal filter material for cement industry, use glass fiber yarn or basalt yarn or metal wire or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com