Drum-type omni-directional turned mass damper

A technology of tuning quality, shock absorption and damping, which is applied in the direction of shock resistance and building components, can solve the problems of high cost, poor effect, and unfavorable wide application of the tuning system, and achieves the effect of flexible layout, simple production and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing:

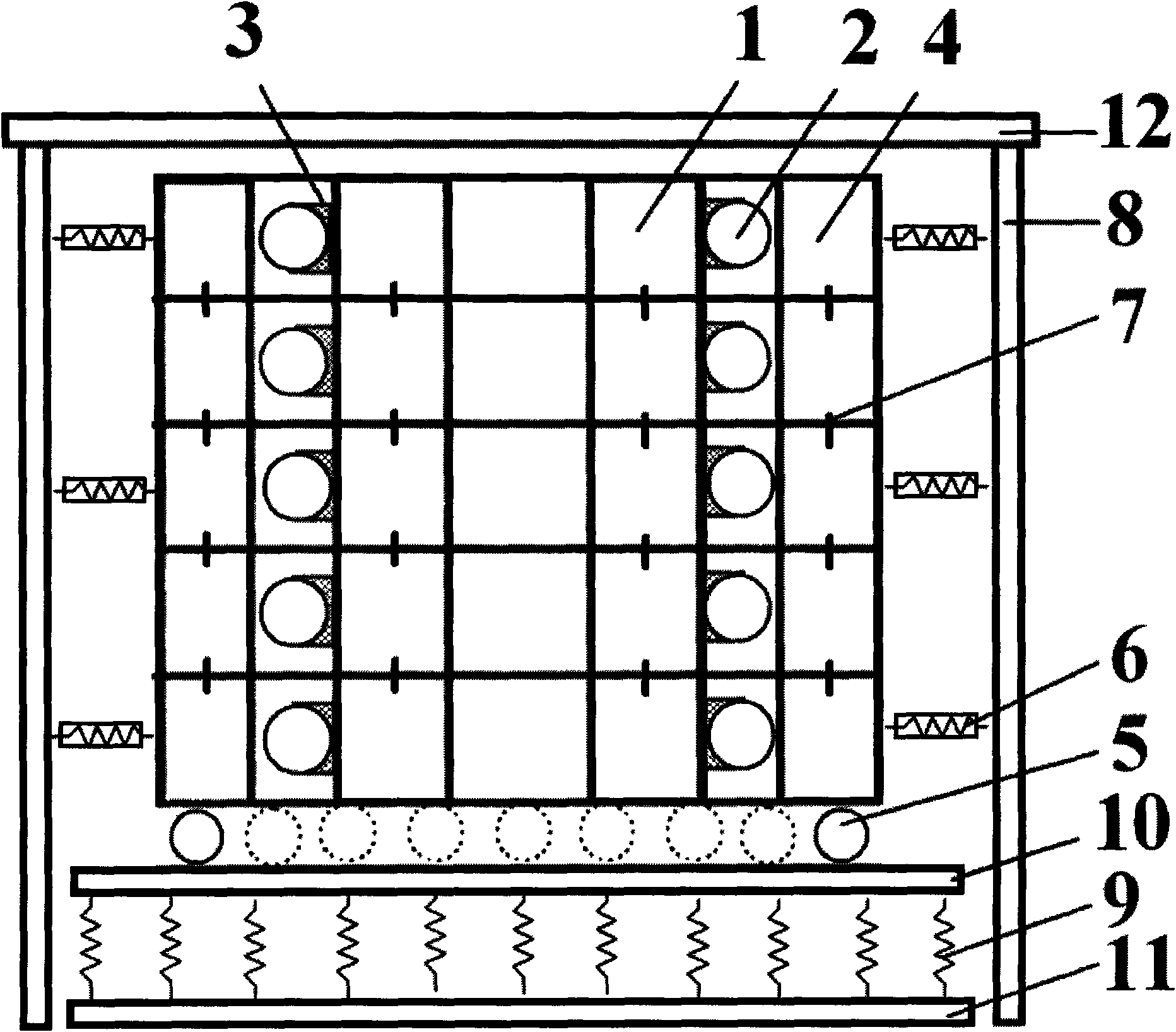

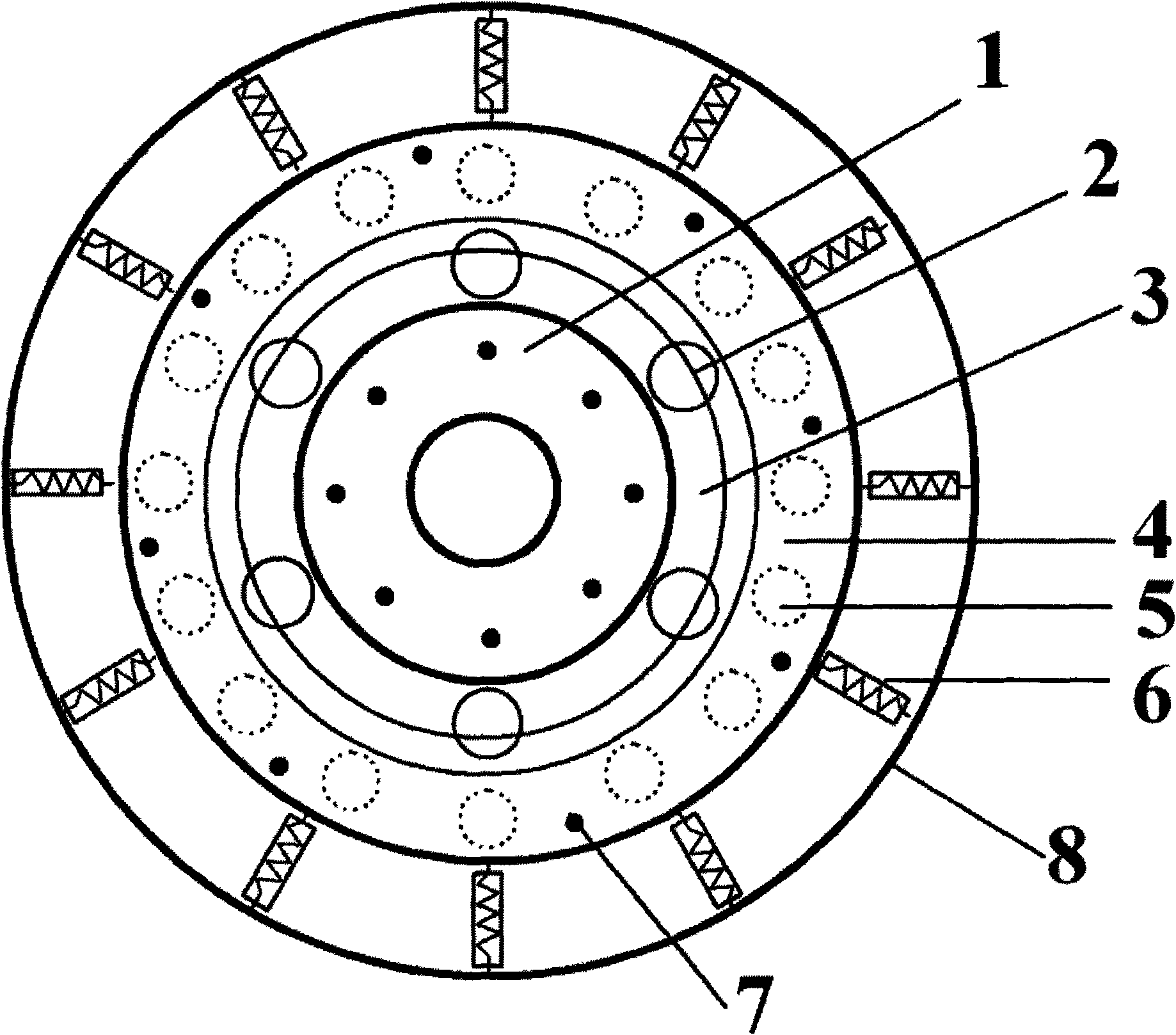

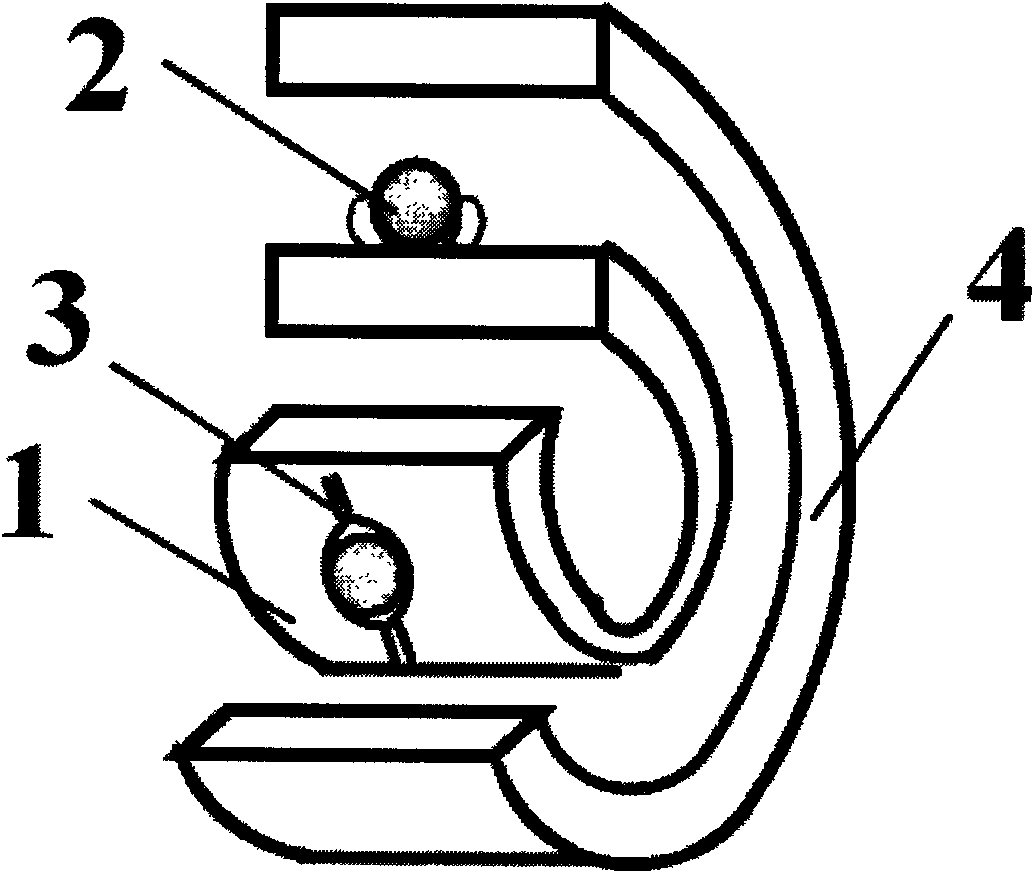

[0023] Such as figure 1 , figure 2 As shown, this embodiment includes a top cover plate 12 , an outer wall sleeve 8 , and a sleeve structure arranged inside the outer wall sleeve 8 from top to bottom, an inner horizontal steel partition 10 and an outer horizontal partition 11 . All parts can be steel material or alloy material. The top cover 12 is connected with the upper structure, and the outer wall sleeve 8 is a cylindrical structure with a circular cross section, and its upper end surface is connected with the lower surface of the top cover 12 . The sleeve type structure includes the inner ring core tube 1, the outer ring core tube 4, the steel ball holder 3 and the steel ball 2. The inner ring core tube 1 and the outer ring core tube 4 have the same structure. The vertical direction is composed of rivets 7 superimposed and fixed together. The structure of the core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com