Spring-open type fuel tank lock

A pop-up, fuel tank technology, applied in the field of fuel tank locks, can solve problems such as inability to apply, affecting the maneuverability of motorcycle 1, affecting driving safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of a preferred embodiment with reference to the drawings.

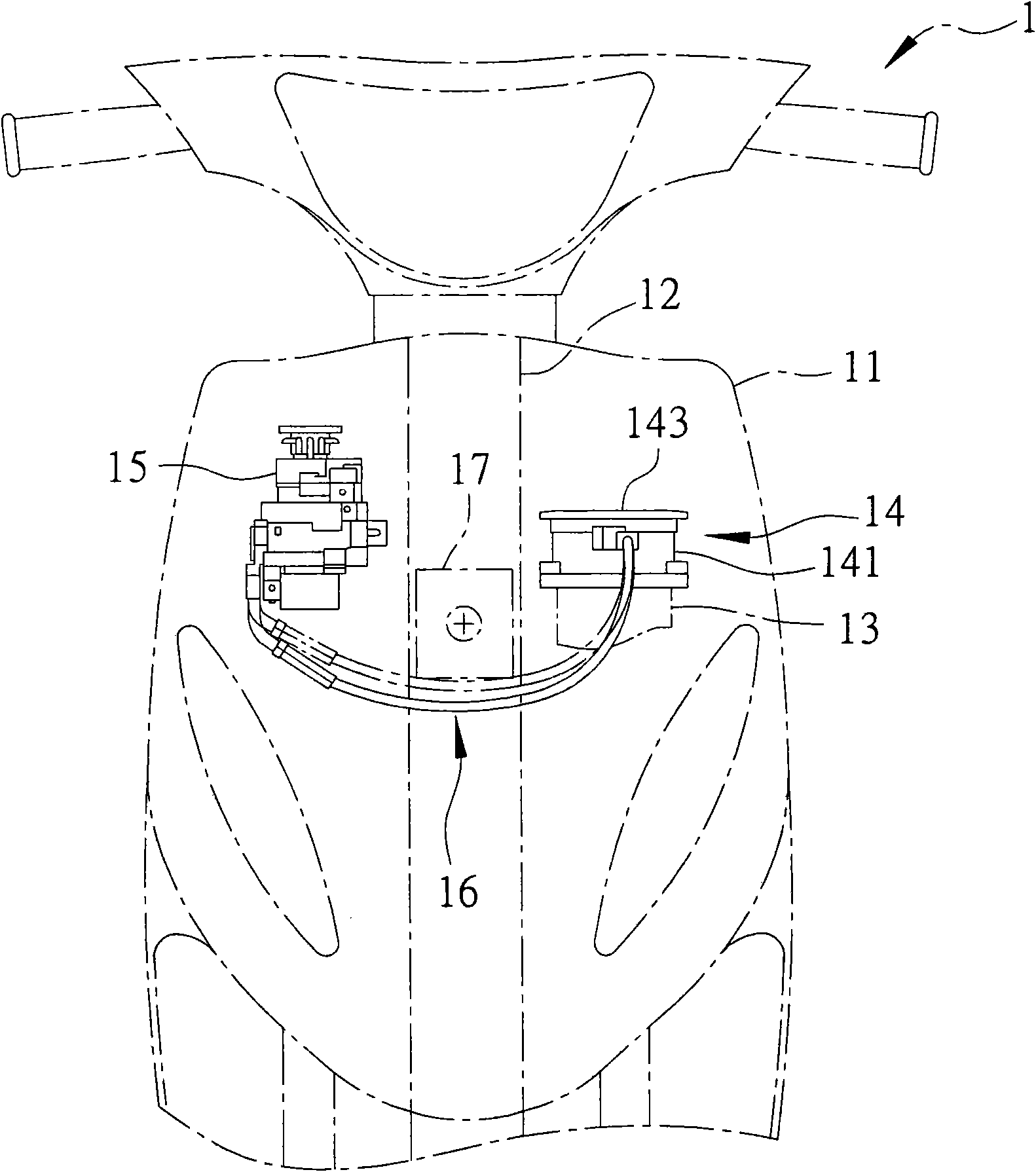

[0038] refer to Figure 4 , 5 , the preferred embodiment of the flick-open fuel tank lock 2 of the present invention is installed on a motorcycle 3, and the motorcycle 3 includes a car shell 31, a head pipe 32 that passes through the car shell 31, and is located at An oil filler 33 and a switch lock 34 on both sides of the head pipe 32 , and a coupling frame 35 arranged on the head pipe 32 for connecting the vehicle shell 31 and the head pipe 32 .

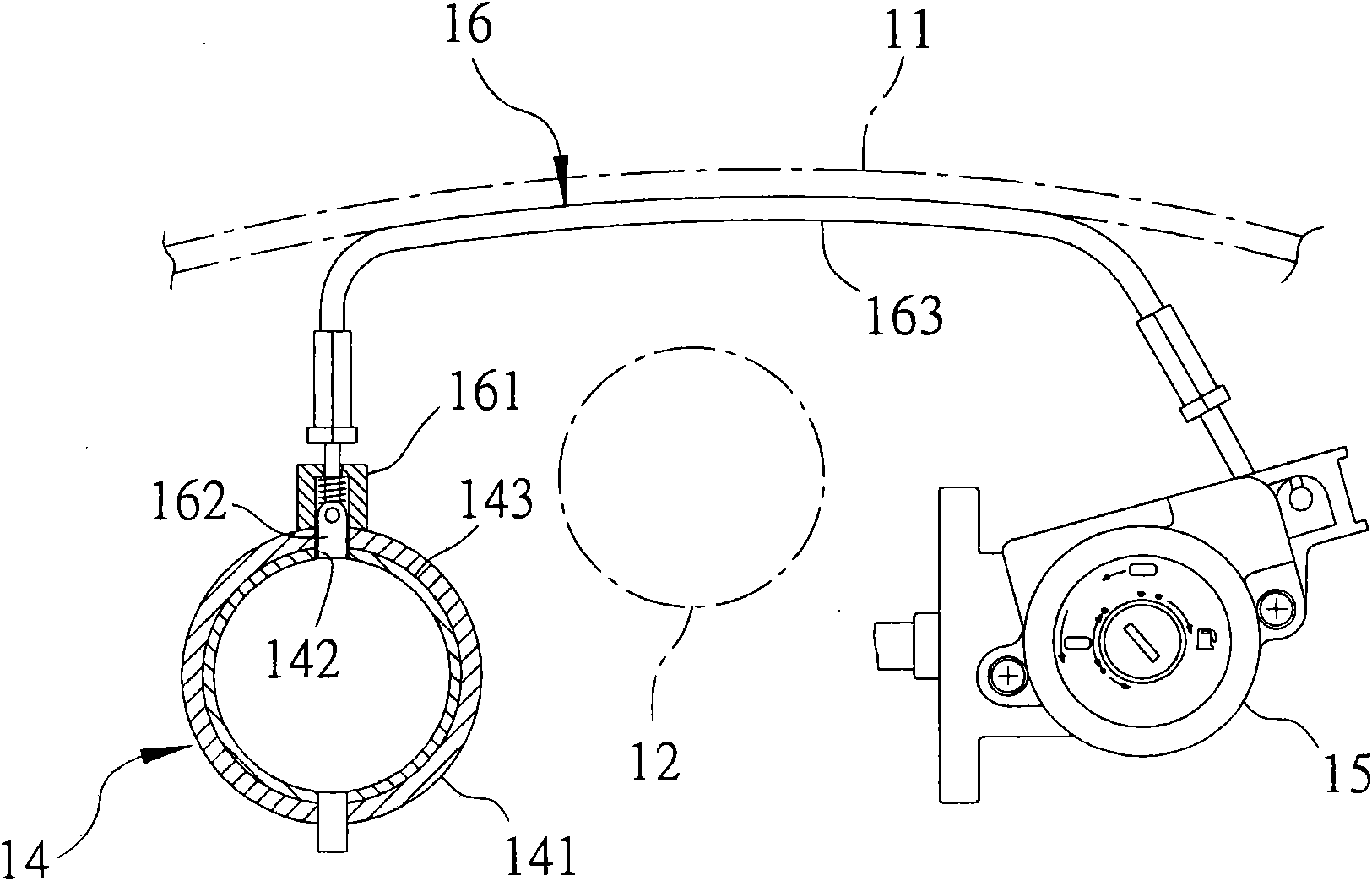

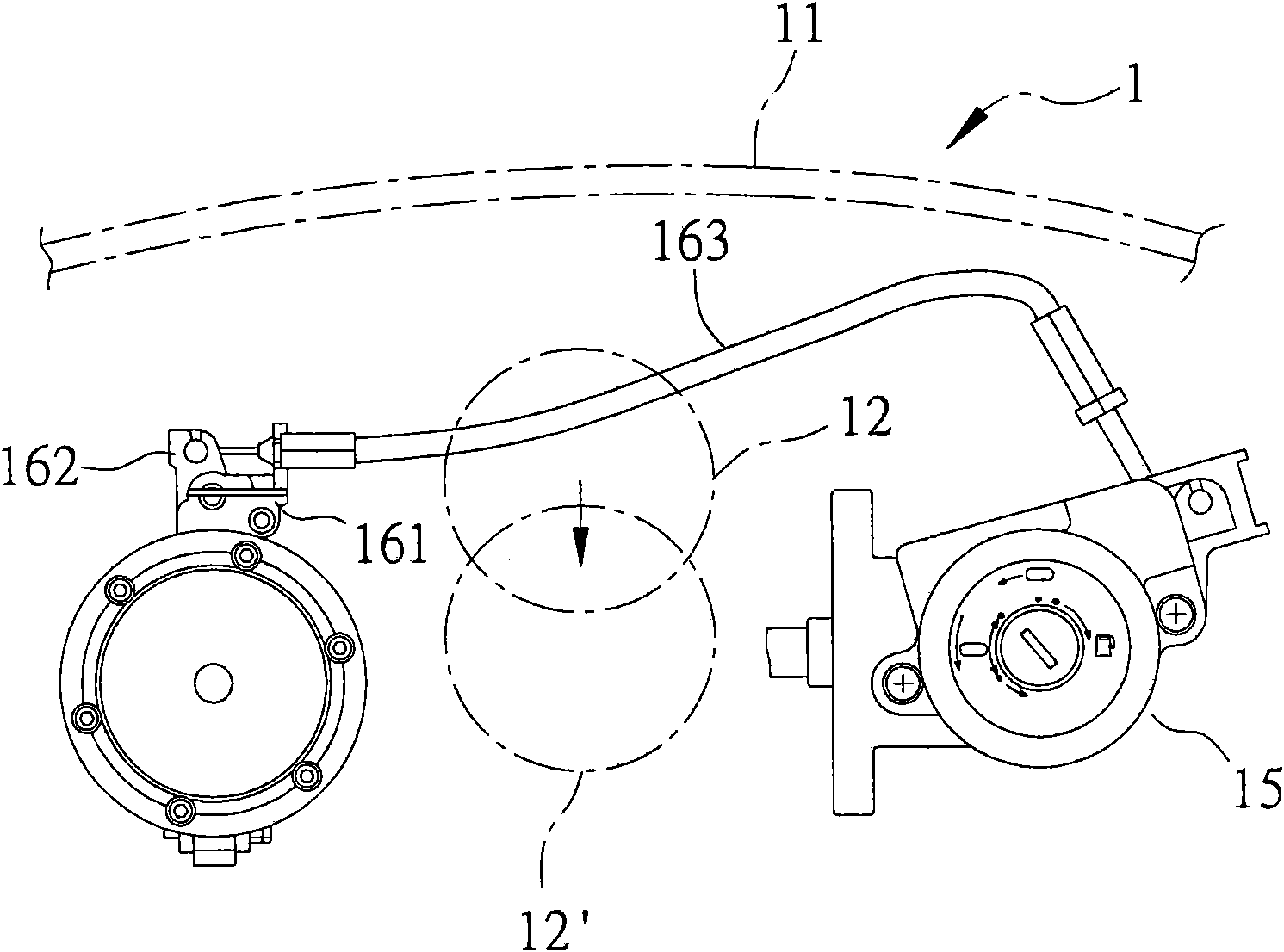

[0039] refer to Image 6 The pop-up fuel tank lock 2 includes a hollow joint seat 21 arranged on the oil filler port 33, a fuel tank cap 22 pivotally arranged on the joint seat 21, and a lock for locking the fuel tank cap 22. Locking unit 23.

[0040] refer to Figure 4 , 5 , 6, the combination seat 21 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com