Floating platform for operation in regions exposed to extreme weather conditions

A floating platform and operation technology, applied to buoys, ship parts, floating buildings, etc., can solve the problem that the connection work is easily affected by weather conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

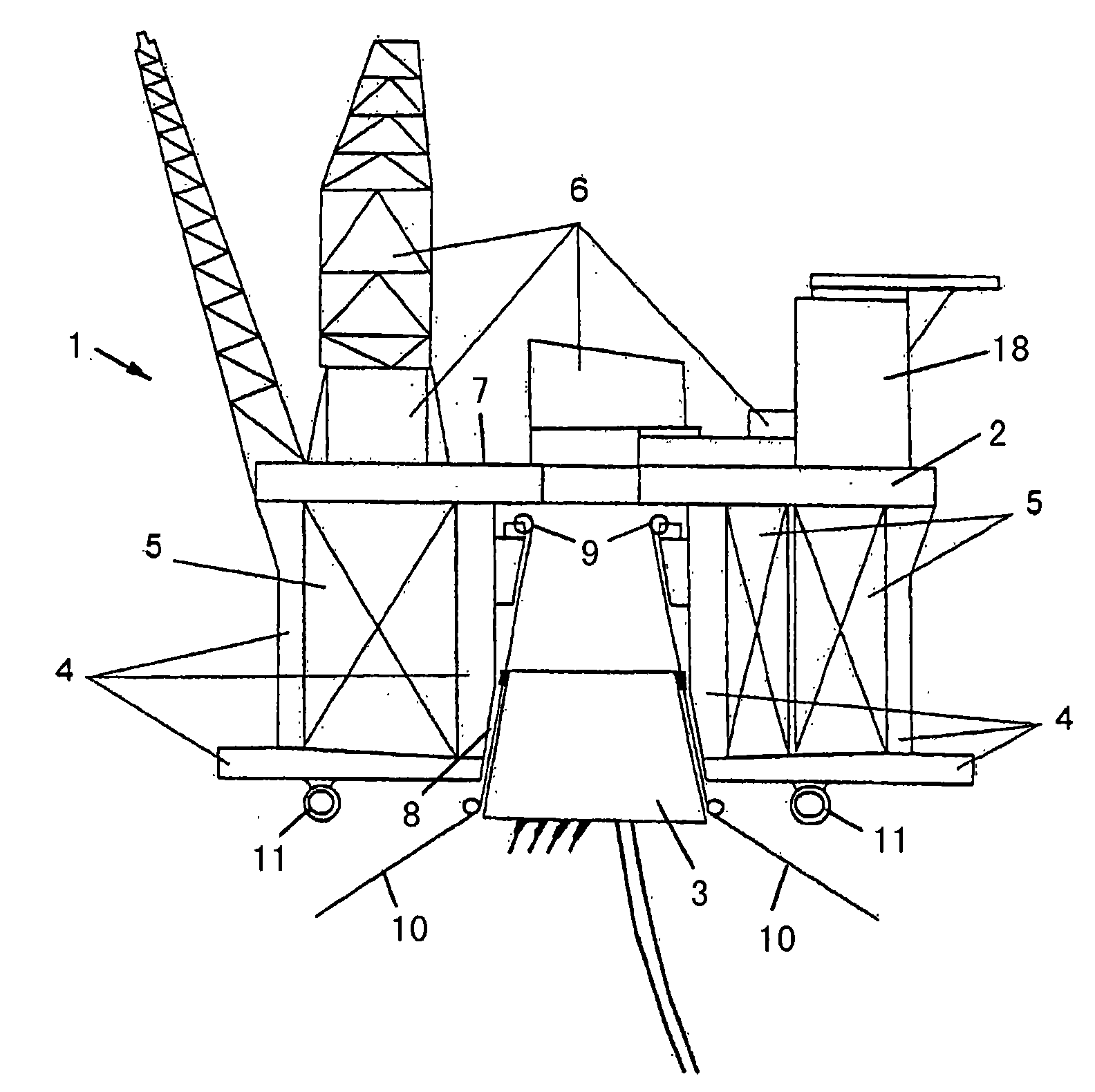

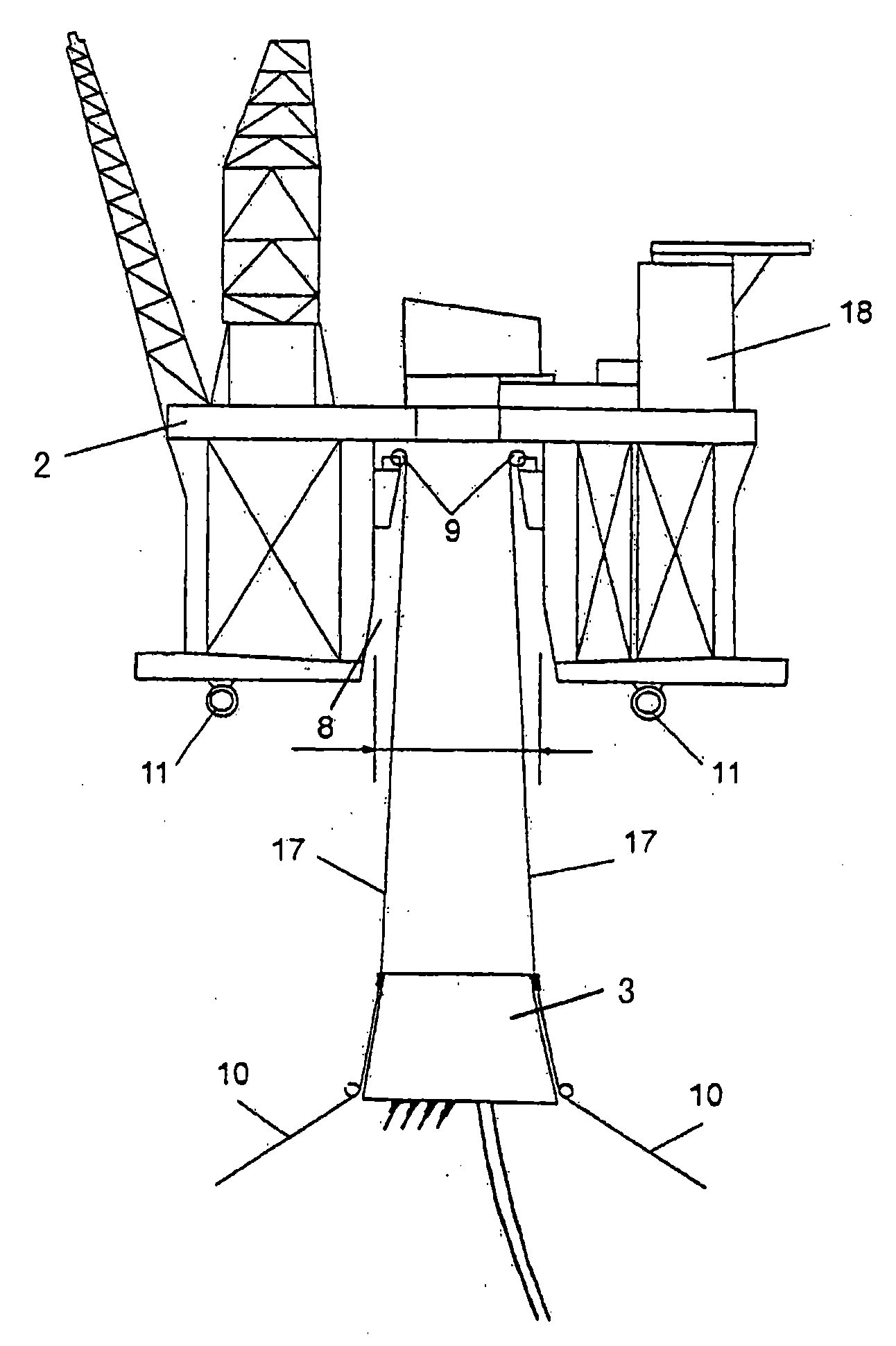

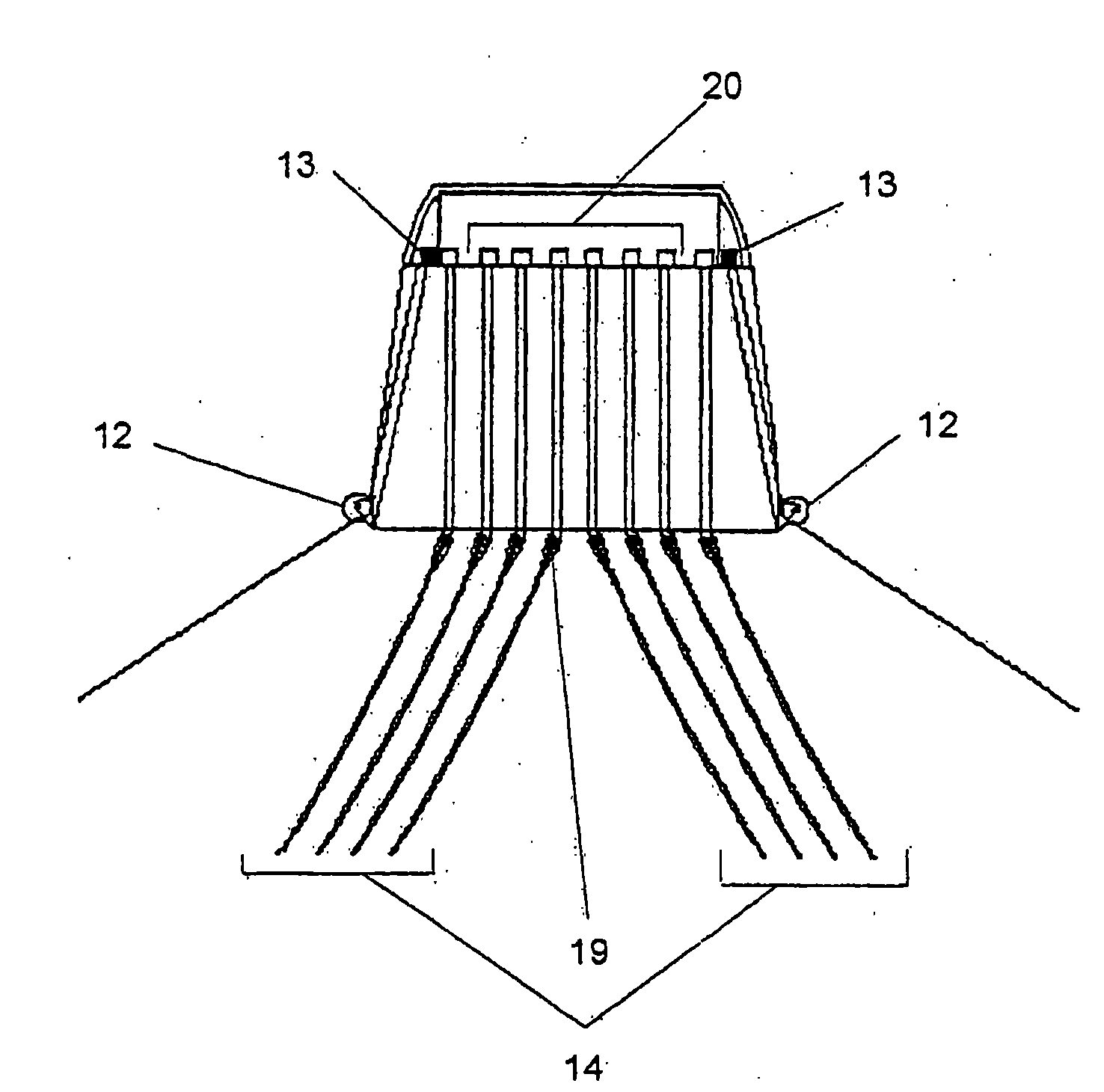

[0015] Such as figure 1 and figure 2 As shown, the illustrated embodiment of a platform building 1 according to the invention comprises a main platform 2 and mooring means comprising a submerged mooring buoy 3 . In a corresponding manner as in the introductoryly described patent specification, the main platform 2 is designed as a vertical, substantially flat-bottomed cylinder. Platforms may have circular or polygonal cross-sections.

[0016] Unlike previously known platforms, the cylinder in this case is provided with a vertical shaft 8 in the center, the lower end of which is adapted to receive and releasably lock the mooring buoy 3 . The platform has two walls and possibly two bottoms used as ballast tanks 4 . They are divided into a sufficient number of bins to ensure handling of damage stability etc. A packing storage tank 5 is provided inside the ballast tank for storing hydrocarbons. Below the living quarters 18 on the main deck 7 there will be an engine room and v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com