Timepiece component and method for making same

A component and clock technology, applied in the field of clock components and its manufacturing, can solve the problems of fragility and lack of plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

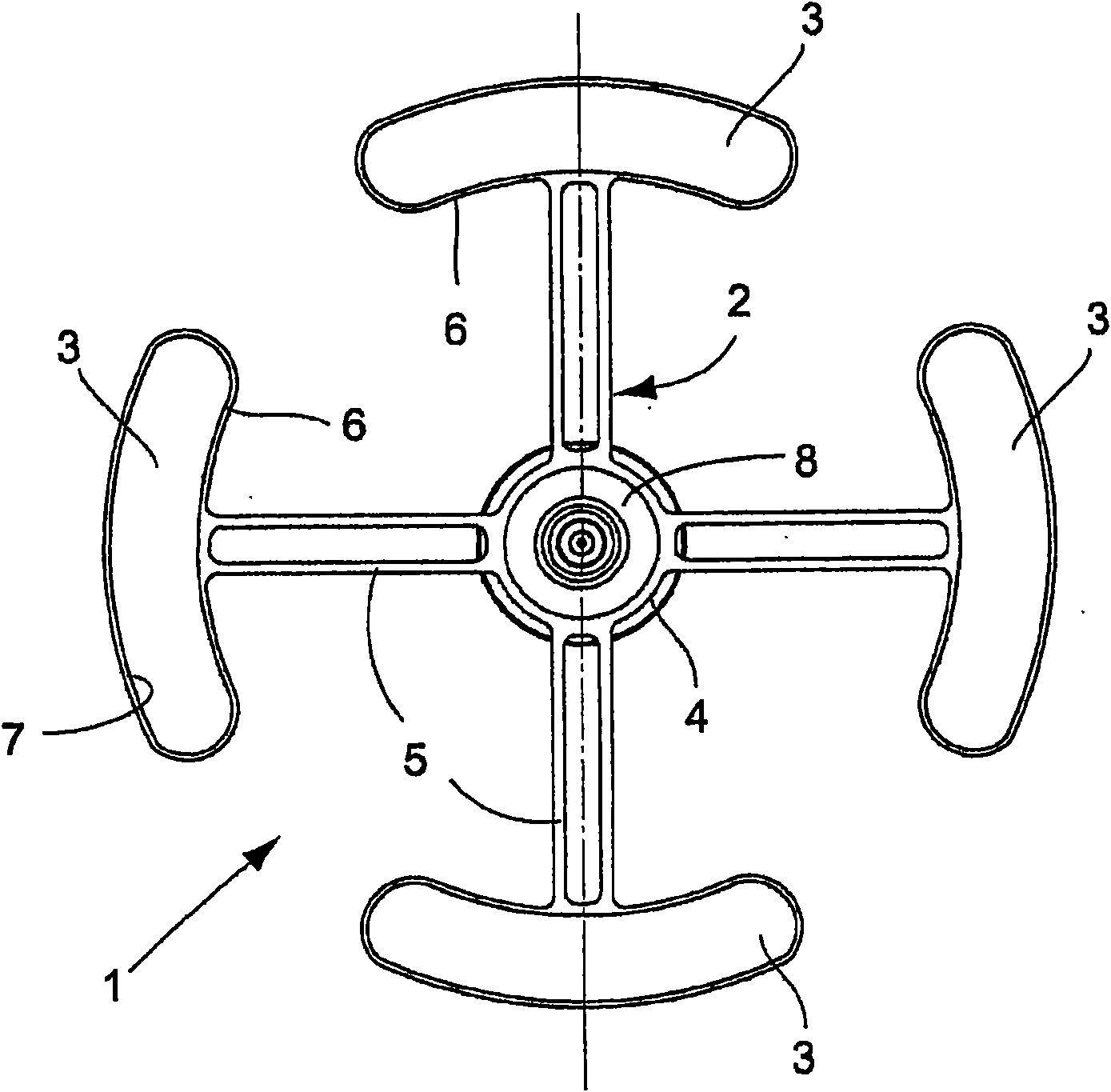

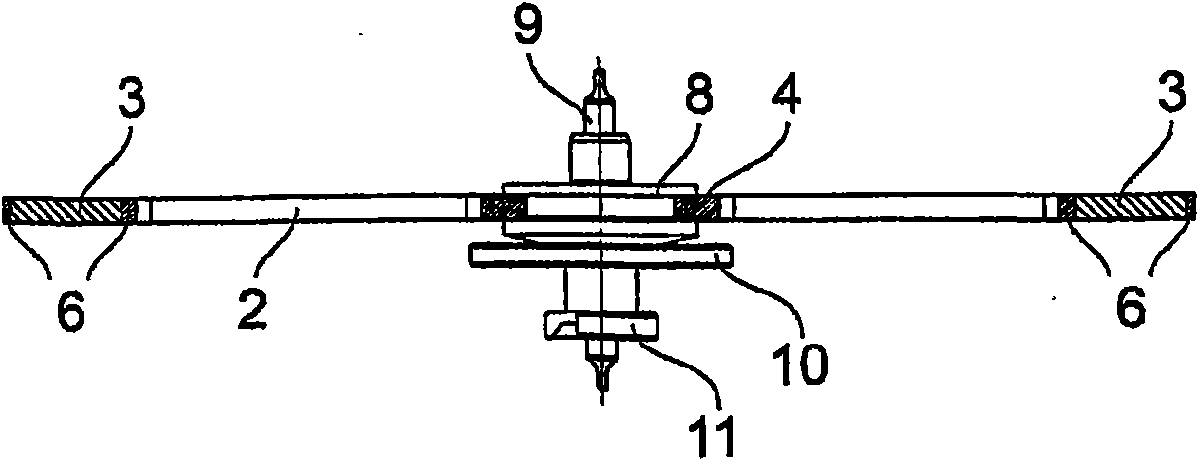

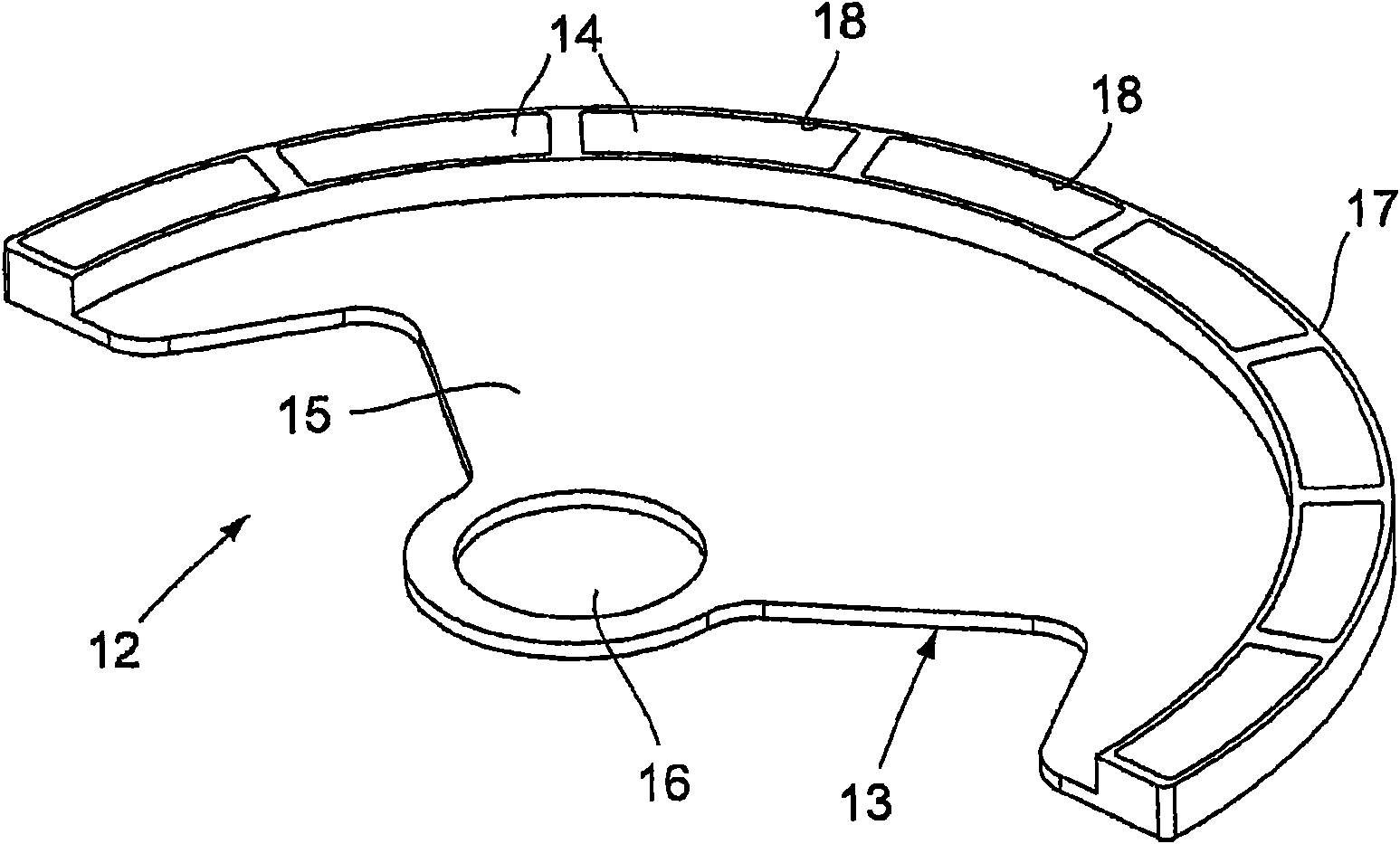

[0021] reference figure 1 According to the present invention, a balance (balance, balance device) 1 for a clock movement (movement) includes a main silicon structure 2 and a metal element 3. The silicon structure 2 includes an annular central part 4, arms 5 extending radially from the central part 4, and a closed contour 6 at the ends of these arms 5, the contour 6 defining a through cavity 7, such as a bean shape. The cavities 7 are respectively filled with metal elements 3 and form separate edge sections with these elements 3.

[0022] The metal element 3 is formed of a material having a higher density than silicon. Thus, they make the periphery of the balance 1 heavier and increase the inertia of the balance to achieve the required inertia. The inner part of the balance wheel 1 formed by the central part 4 and the arm 5 is very light because it is formed of silicon and it is largely hollow. Since the internal components of the balance wheel have less influence on the inertia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com