Optimized register control process in a sheet-fed printing press

A printing press, sheet-fed technology, applied in printing presses, general parts of printing machinery, printing, etc., can solve the problems of different moving paths, without considering overprint adjustment, etc., to achieve the effect of rapid adjustment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

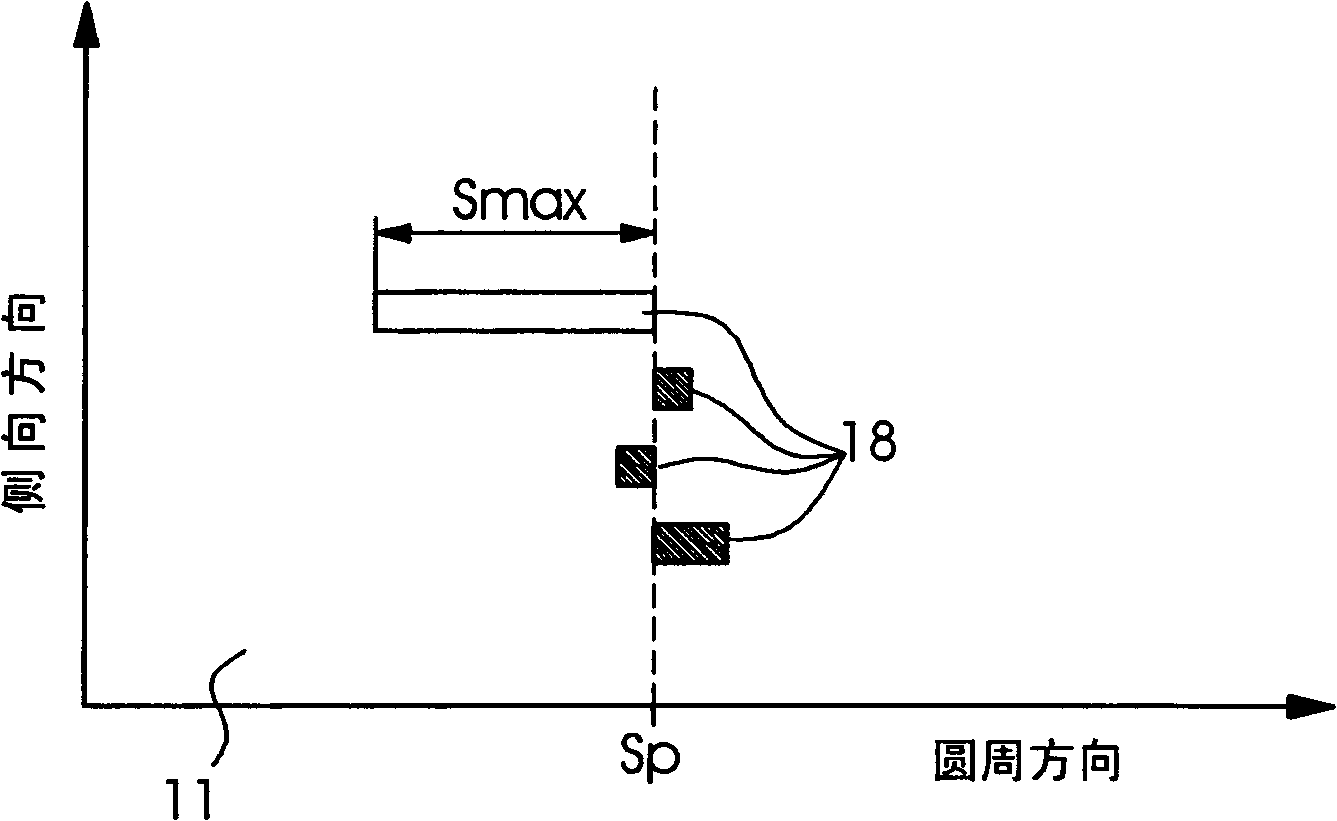

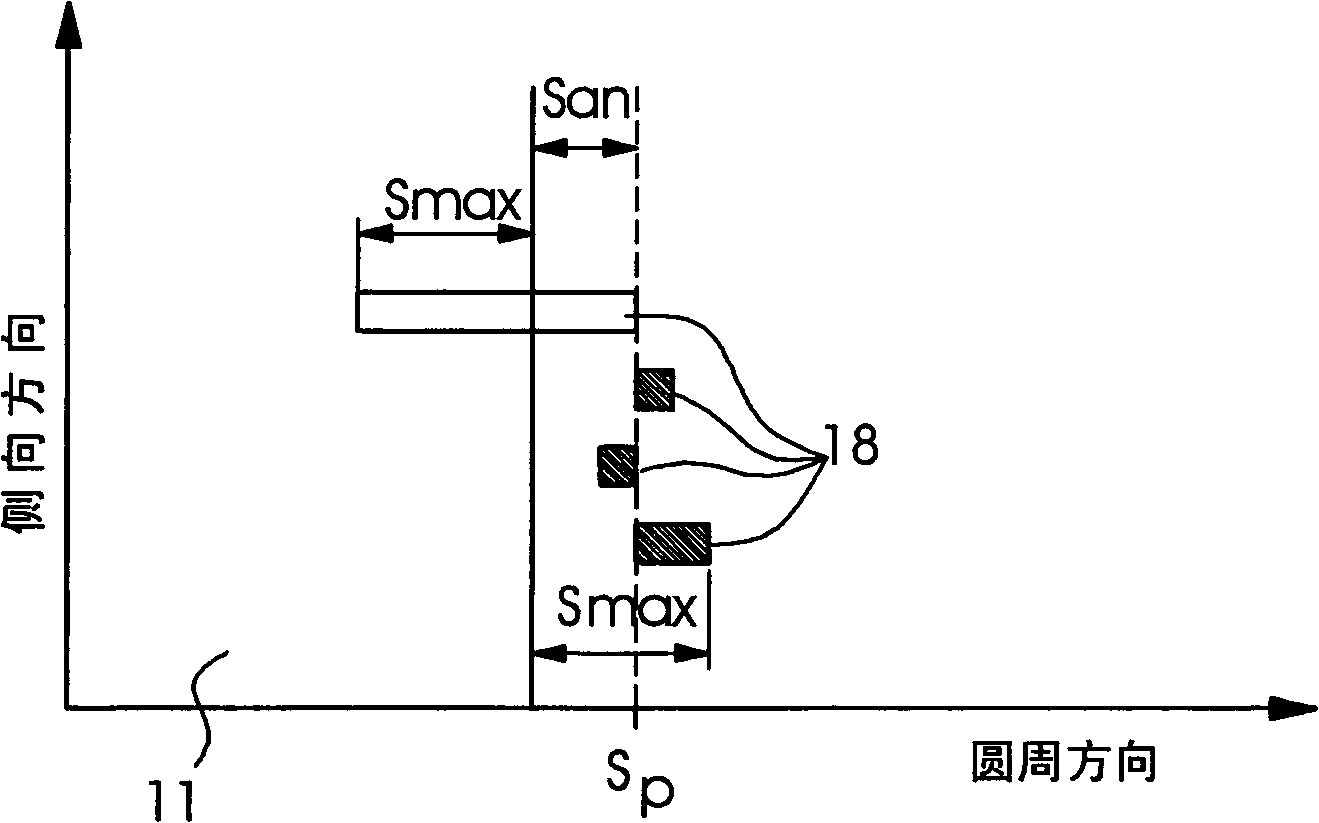

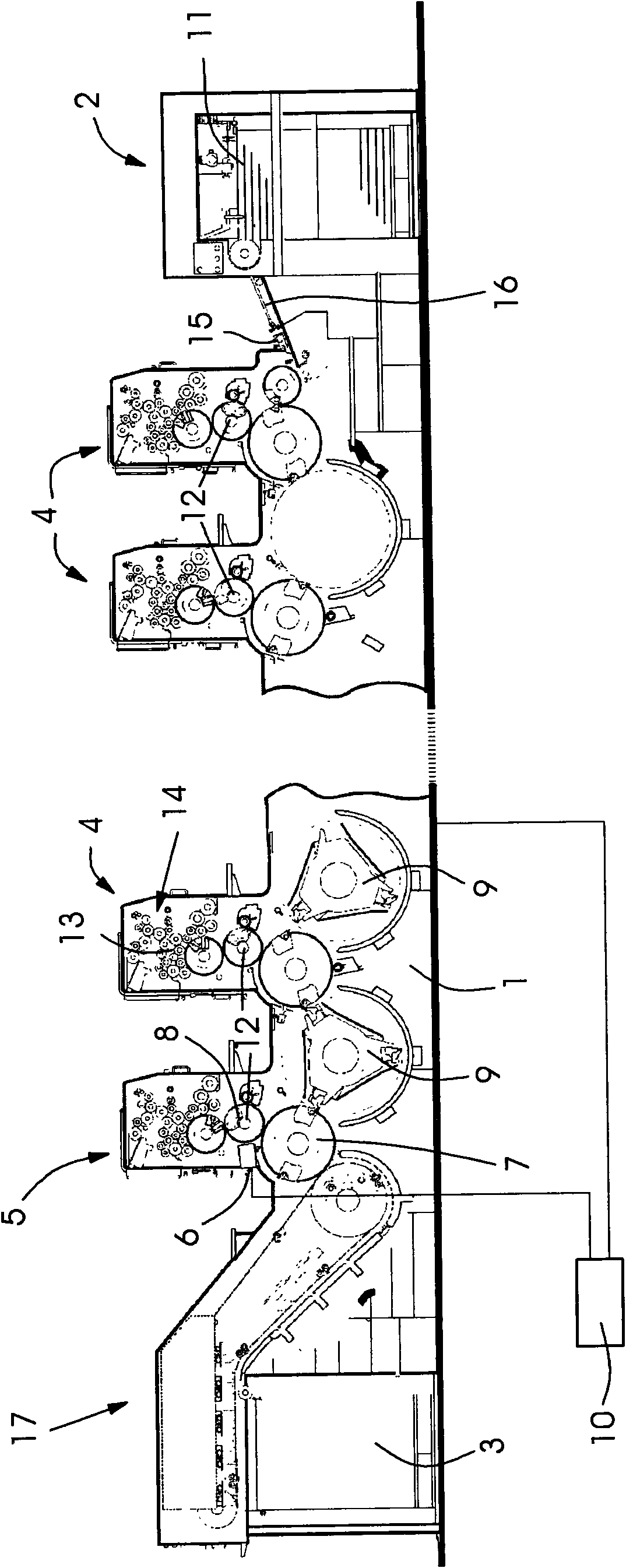

[0018] exist figure 1 A sheet 11 is shown in the image 3 Measured by the register sensor 6 in the sheet-fed printing press 1 shown in . The deviation 18 determined here is relative to the specified position Sp which gives the desired position of the printed image in the circumferential direction relative to the side edge of the sheet 11 . exist figure 1 In , the largest deviation from a given position Sp is found at the color separation "yellow" of the printed color. In this case, the maximum deviation 18 is characterized by Smax. To thereby place all separations in figure 1 In order for the coordination and overprinting to be corrected precisely at a given position Sp, the yellow separation must be corrected with the maximum travel path Smax. This means that the much longer travel path Smax compared to the other color separations determines the entire length of the adjustment process, so that a very long adjustment process is required. This approach corresponds to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com