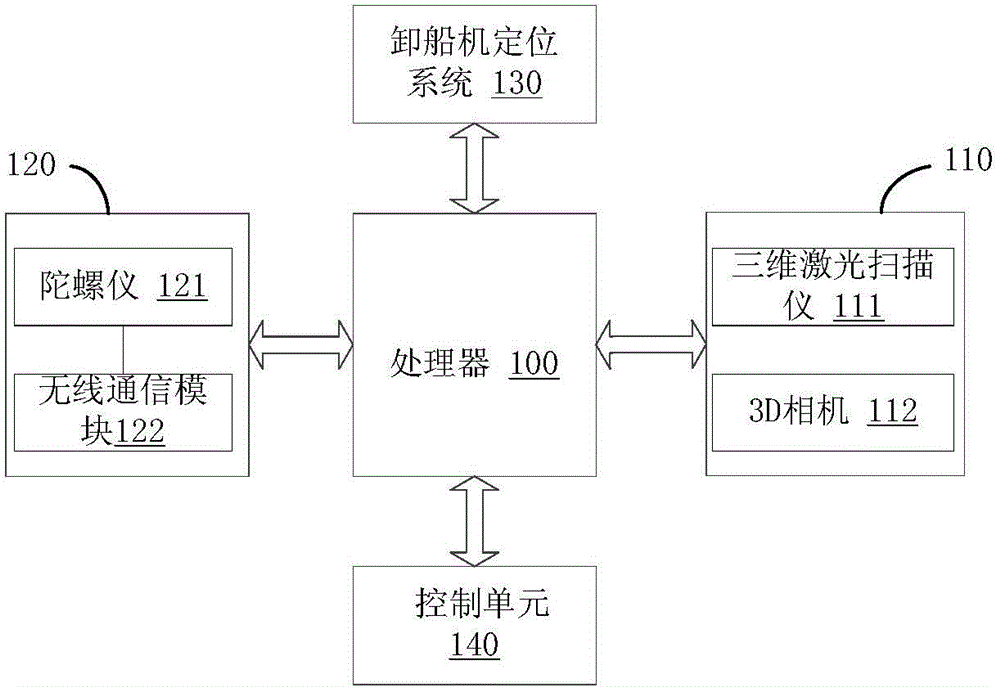

Ship unloader control system and control method

A control system and ship unloader technology, applied in the direction of load hanging components, transportation and packaging, can solve the problems of high operation error and low grasping efficiency, reduce the probability of accidental collision, improve safety and intelligence level, the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

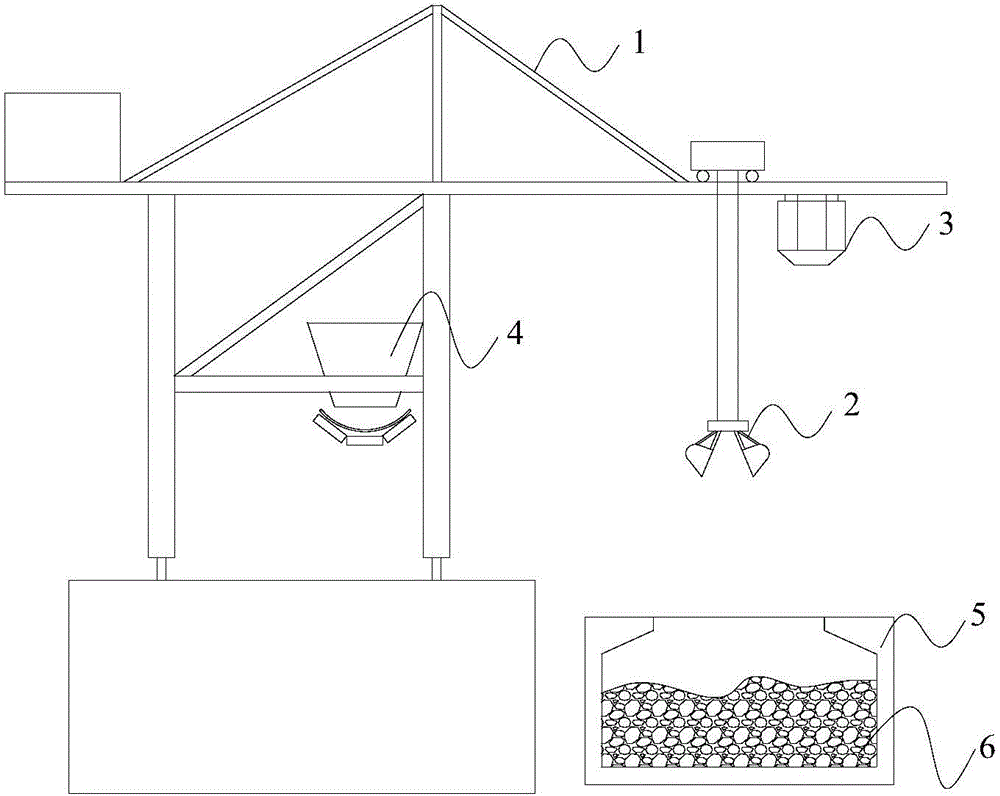

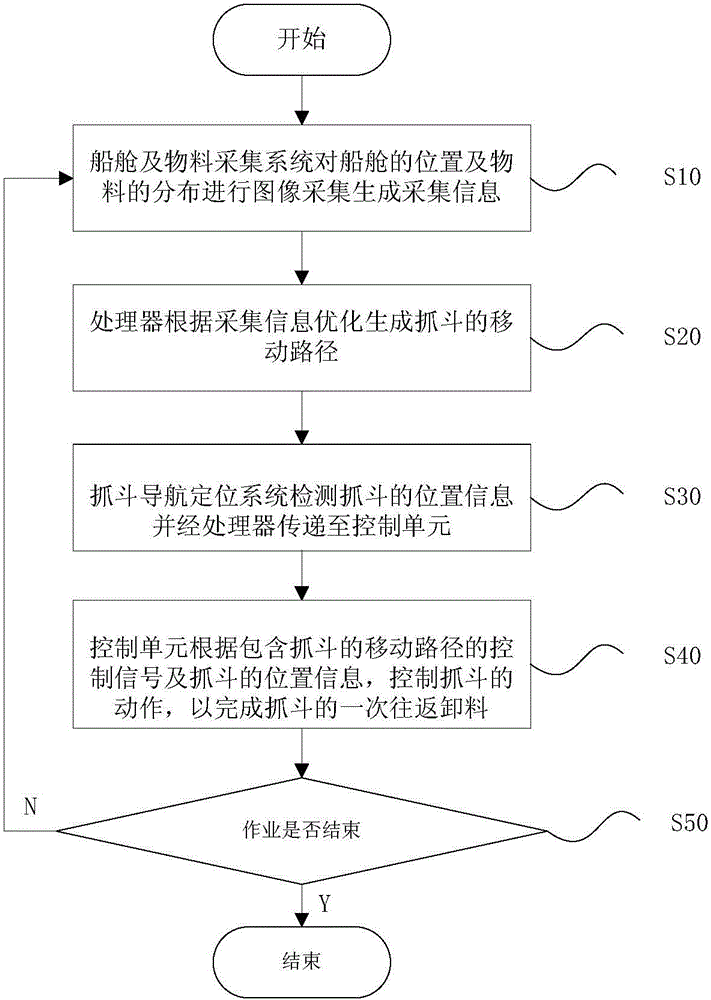

[0040] refer to figure 2 Firstly, briefly introduce the ship unloader using the ship unloader control system and control method of the preferred embodiment of the present invention. When the cargo ship is in port, the ship unloader body 1 moves to the operation destination under the action of the cart, and unloads the ship. The grab bucket 2 of the machine grabs the material 6 in the cabin 5 from a high place. After grabbing the material, the grab bucket 2 moves to the top of the grab bucket discharge bin 4 under the control of the driving mechanism, and the material 6 is released by the grab bucket. Material bin 4 falls on the ground conveying device and is transported away. However, the control of the existing grab bucket 2 requires the driver t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com