Fixing seat of needle selector of circular knitting machine

A needle selector and circular knitting technology, which is applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of increasing the failure rate of circular knitting machines, high requirements on installation accuracy and processing accuracy, and achieves the requirements for reducing processing accuracy and reducing Requirements for installation accuracy and the effect of preventing excessive damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

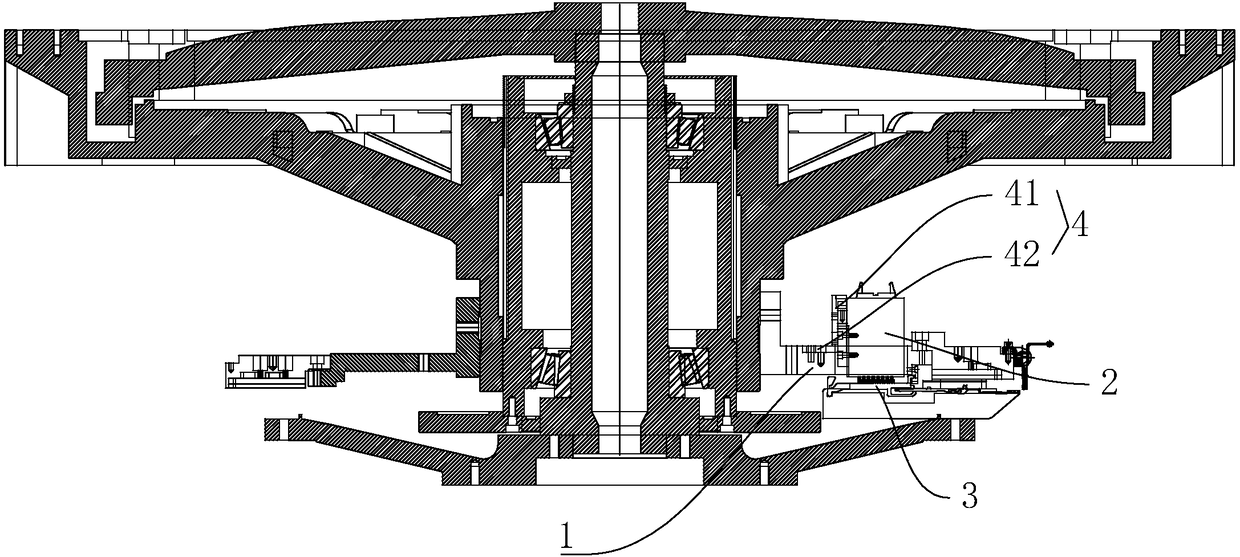

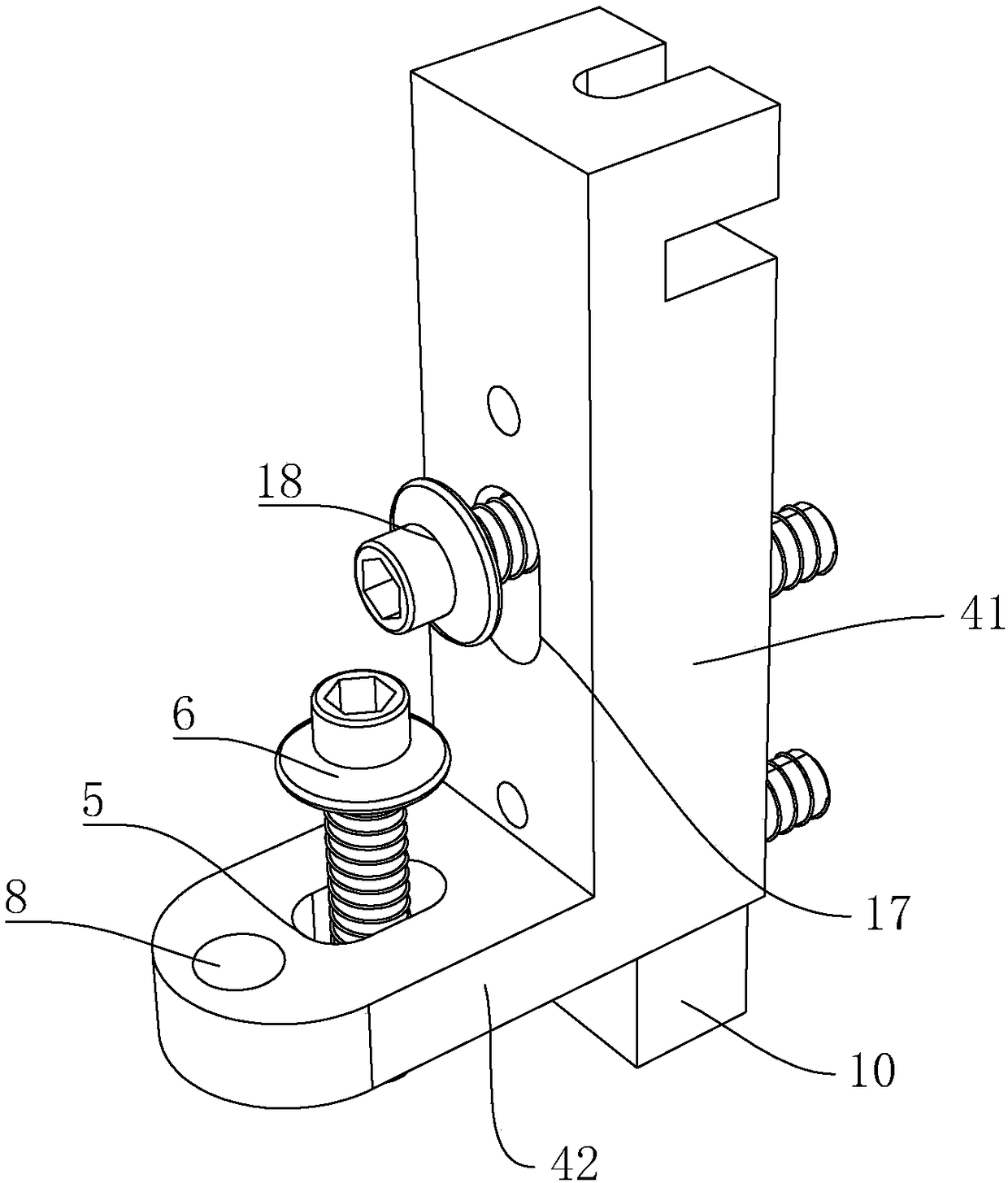

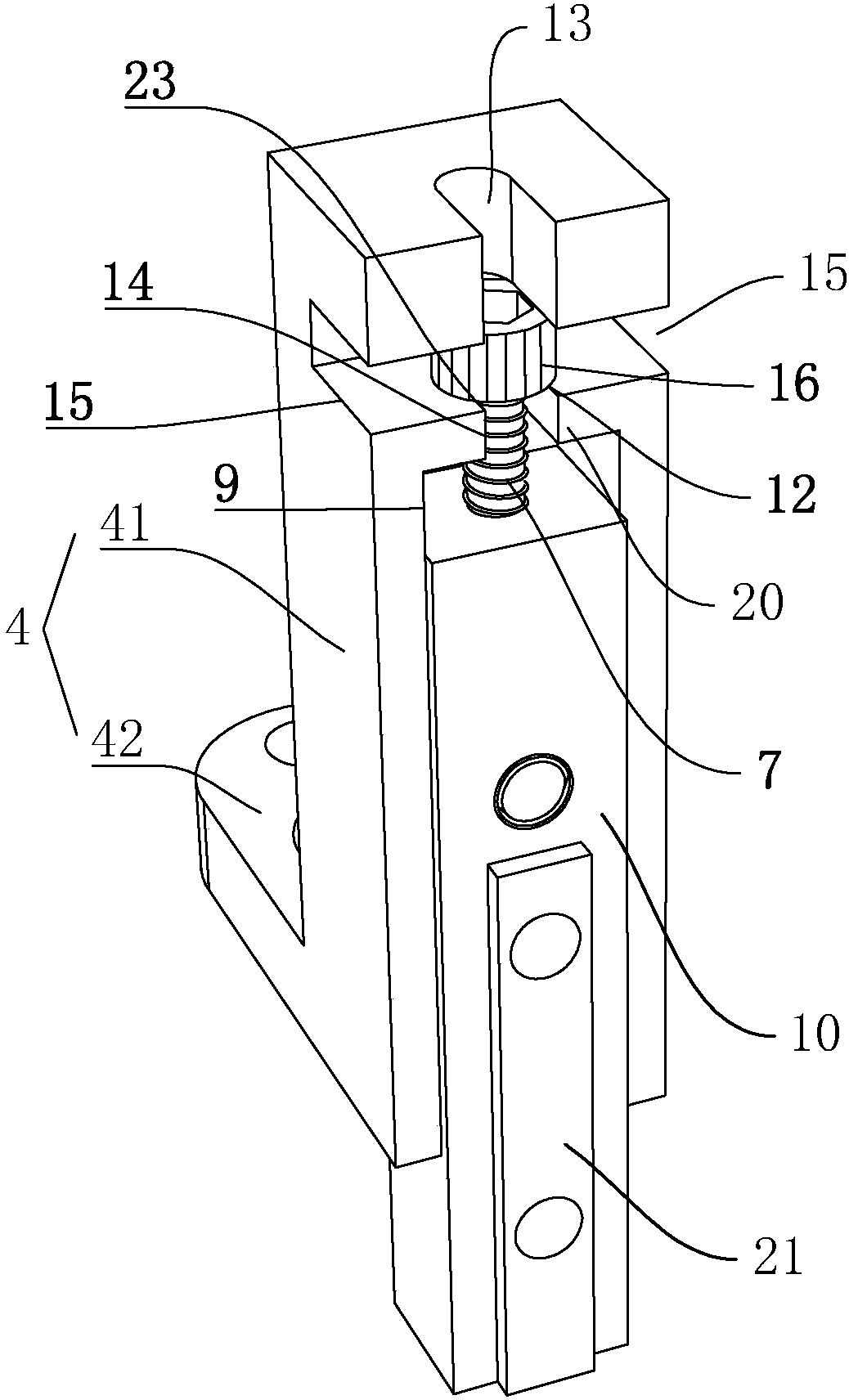

[0034] A fixing seat for the needle selector 2 of a large circular knitting machine, refer to figure 1 , including a horizontally arranged middle kernel 1, a jacquard sheet 3 arranged parallel to the middle kernel 1 is arranged below the middle kernel 1, and the jacquard sheet 3 and the middle kernel 1 are dislocated. The upper surface of Zhongren 1 is provided with an L-shaped seat body 4, and the L-shaped seat body 4 is separately named as a horizontal portion 42 arranged horizontally and a vertical portion 41 arranged vertically. A needle selector 2 is provided on the other side of the vertical part 41 relative to the horizontal part 42, and the needle selector 2 is located directly above the jacquard piece 3; 3 contact positions for a tighter fit.

[0035] refer to figure 2 , the upper surface of the horizontal part 42 is provided with a circular posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com