Improved carbon brush holder

A carbon brush holder and conductive holder technology, applied in current collectors, electrical components, rotary current collectors, etc., can solve problems such as increased impedance and arc discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

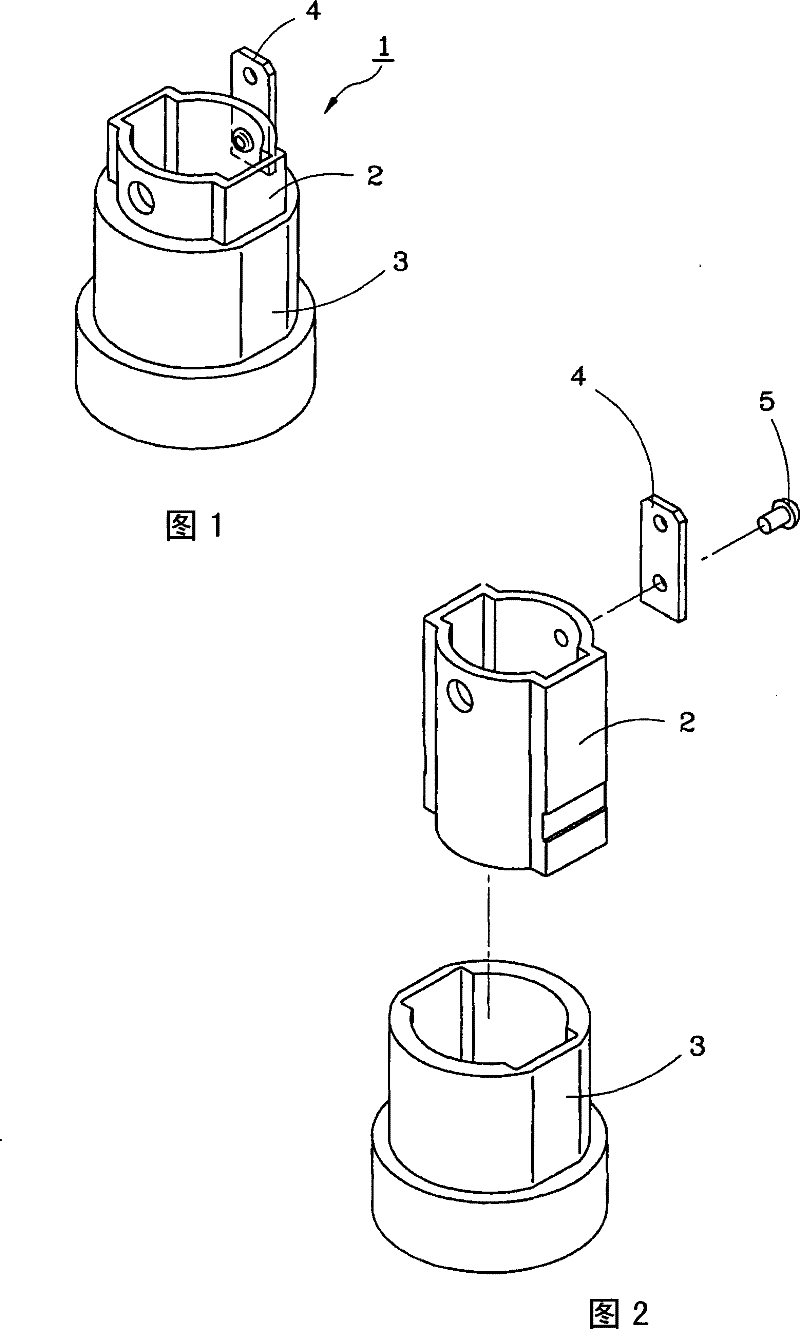

[0023] see Image 6 and Figure 7 As shown, the carbon brush holder 100 provided by a preferred embodiment of the present invention is mainly composed of a conductive holder 20 , a terminal piece 30 , a rivet 40 and an insulating holder 50 .

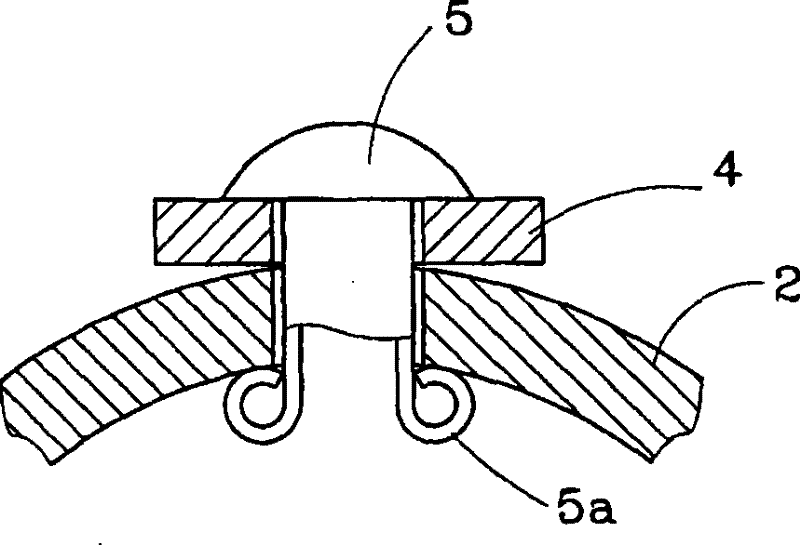

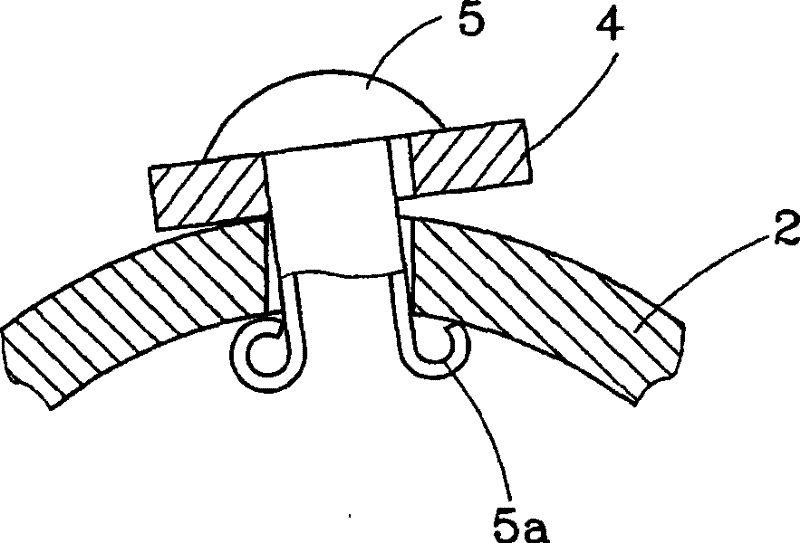

[0024] The insulating seat 50 is a cylinder made of bakelite or other insulating materials, and has a hole in its center. The conductive base 20 is made of copper or other conductive materials, its shape is consistent with the hole of the insulating base 50 , and can be inserted into the insulating base 50 for fixing. The conductive seat 20 has a part exposed on the insulating seat 50 , and a through hole 21 and a fixing hole 22 are disposed on the exposed part. The conductive end piece 30 defines a fixing hole 31 . The rivet 40 has a head 41 and a post 42. After the post 42 passes through the fixing hole 31 of the conductive end piece 30 and the fixing hole 22 of the conductive base 20, a rivet gun (not shown) is used to The column ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com