Conveying roller shaft

A technology of conveying rollers and conveying roller tables, which is applied in the direction of conveyor objects, rollers, transportation and packaging, etc., which can solve the problems of inconvenient installation, complicated processing, and high noise, and achieve convenient processing, reduce pollution, and reduce noise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention will be further described below in conjunction with the embodiments in the accompanying drawings.

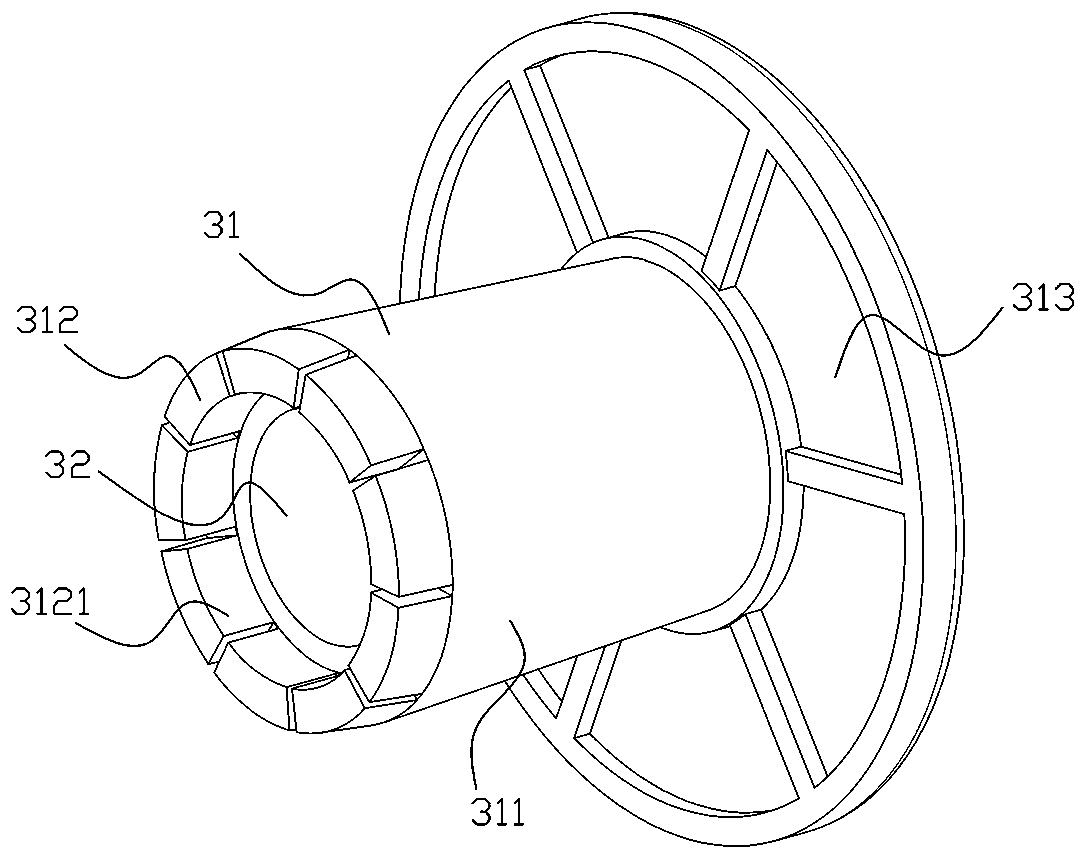

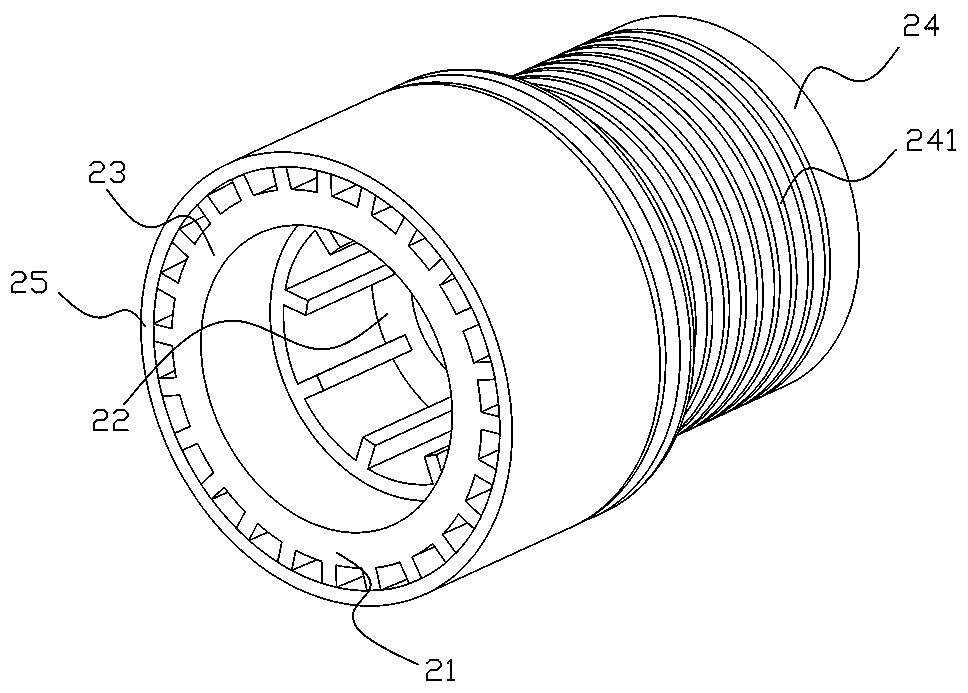

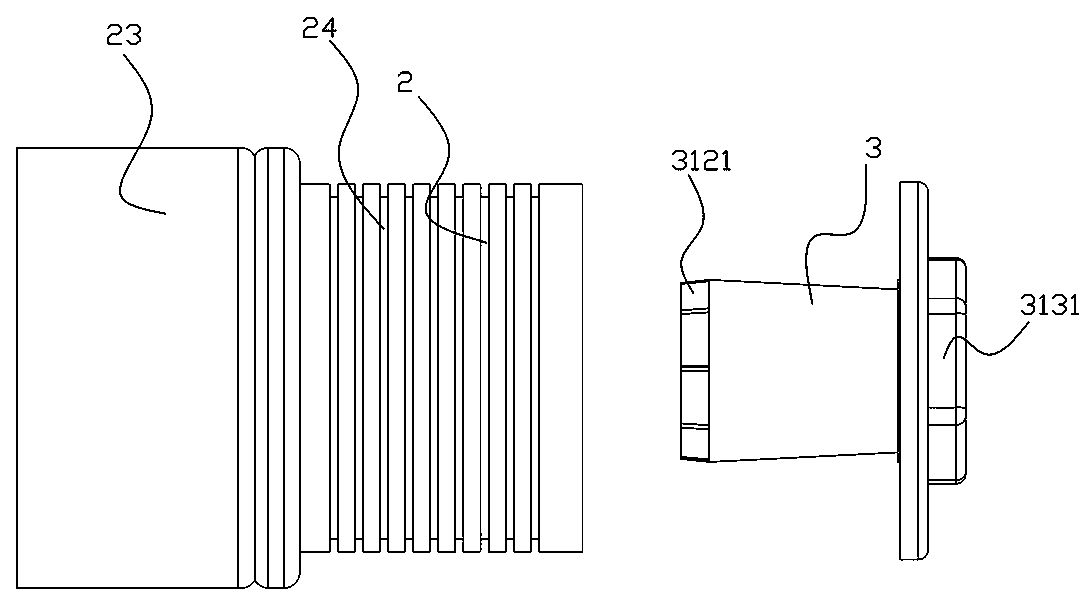

[0024] Such as Figure 1 to Figure 4 The conveying roller shaft shown includes a drum 1 and an inner sleeve 2 located on the side of the drum 1, the end of the inner sleeve 2 is provided with a connecting piece 3, and one end of the connecting piece 3 is fixed on the frame of the conveying roller table. It is characterized in that: the inner shaft sleeve 2 includes a sleeve body 21 and a retaining ring 22 inside the sleeve body 21 , the connector 3 includes a connecting body 31 and a threaded body 32 inside the connecting body 31 , and the threaded body 32 is provided with internal threads. The retaining ring 22 can be an annular structure that is integrally injection molded and connected or interference-connected in the sleeve body 21 , or can be a bearing inner ring structure of a bearing disposed in the sleeve body 21 . The threaded body 32 has a first m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com