Sensor assembling seat and assembling method thereof

An assembly method and sensor technology, applied in the direction of instruments, measuring devices, measuring instrument components, etc., can solve the problems of low efficiency, messiness, and many wires, so as to reduce the probability of defective products, improve assembly efficiency, and reduce assembly processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

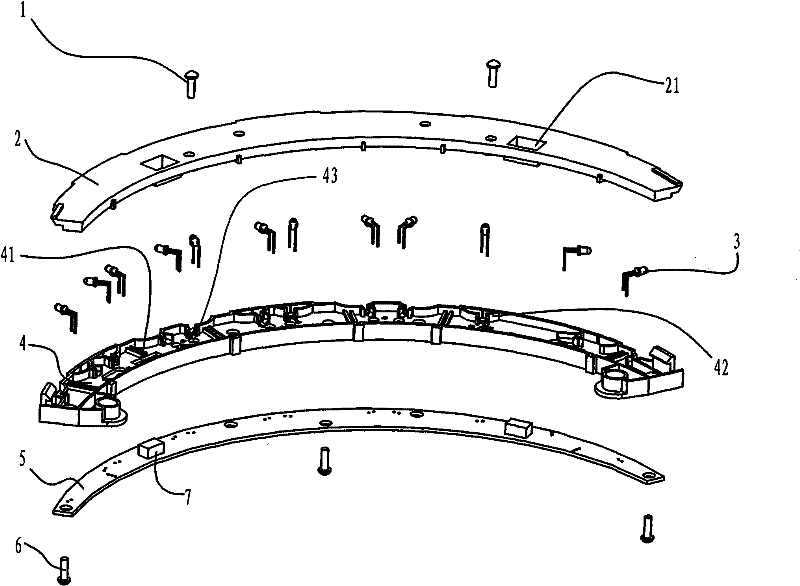

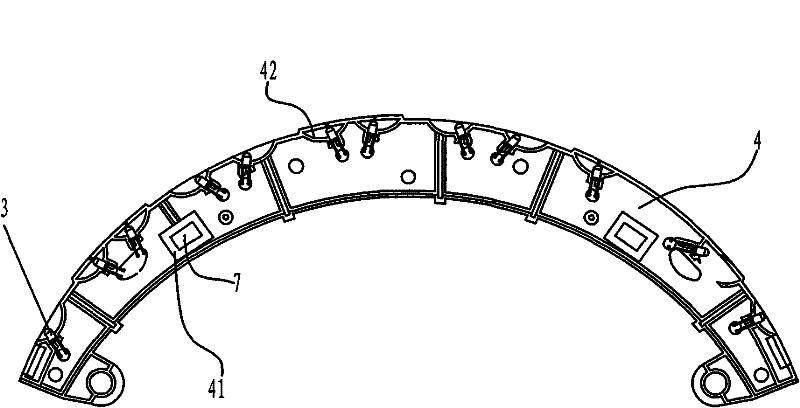

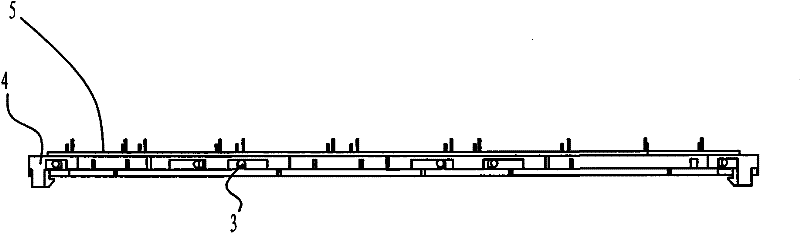

[0027] like figure 1 , the sensor mounting seat in the best embodiment of the present invention comprises a sensor base 4 and a sensor circuit board 5, a plurality of sensors 3 can be installed on the sensor base 4, and receive external signals through the sensors 3, such as For video signals, audio signals, etc., the sensor circuit board 5 is provided with a signal output socket 7 that outputs external signals received by the sensor 3 to the processor. In this embodiment, the signal output socket 7 is in the shape of a rectangular cube and is supported on the On the sensor circuit board 5. A sensor upper cover 2 for covering the sensor base 4 is also arranged above the sensor base 4. The sensor base 4 is arranged between the sensor upper cover 2 and the sensor circuit board 5, and is connected by screws. 1 is fixed so that the sensor upper cover 2, the sensor base 4 and the sensor circuit board 5 are fixedly connected together after assembly, and the sensor base 4 is also pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com