Method for manufacturing printed circuit board with half-edge hole

A technology of printed circuit boards and half-side holes, which is applied in the fields of printed circuit, printed circuit manufacturing, and multilayer circuit manufacturing. drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

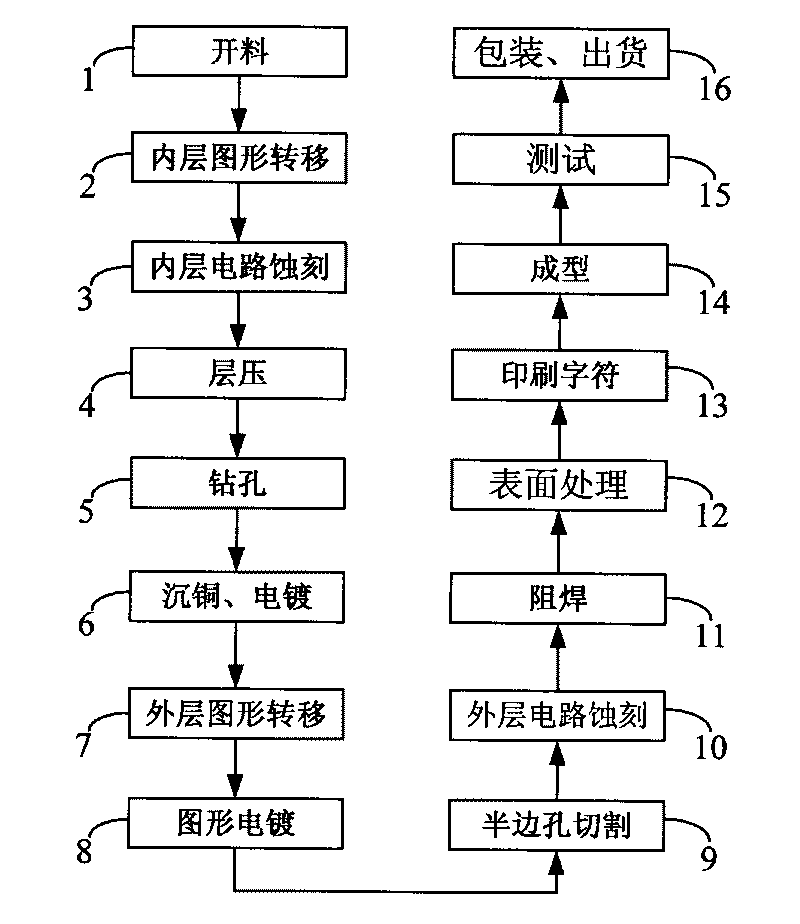

[0024] Embodiments of the present invention will now be described with reference to the drawings, first referring to figure 1 , a method for making a printed circuit board with a half hole in the present embodiment, comprising the steps of:

[0025] (1) The circuit board raw materials of each layer of circuit are cut to form a raw material substrate.

[0026] (2) Transfer the inner layer pattern to each inner layer circuit board to form the inner layer circuit pattern. Since printed circuit boards are usually multi-layer circuit technology, the circuit lines on different layers are different. Therefore, it is necessary to control its circuit lines through the production equipment on each layer, and transfer the inner layer graphics, that is, to make the inner layer circuit graphics.

[0027] (3) Etching the circuit pattern of the inner layer.

[0028] (4) Each layer of the circuit board is then laminated to form a multilayer circuit board.

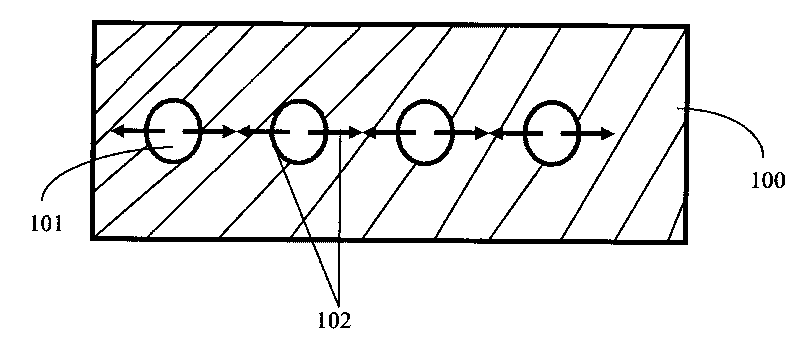

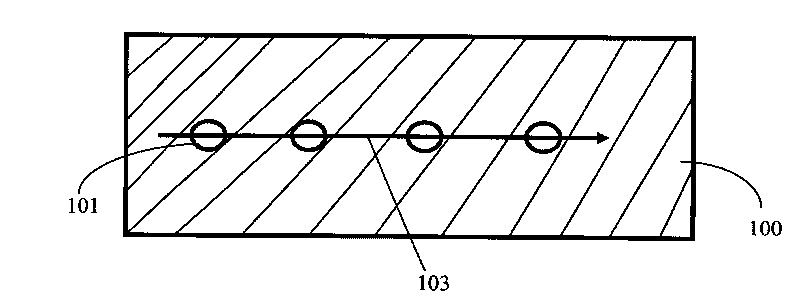

[0029] (5) Drill holes on the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com