Anti-leakage high-voltage electricity leading-in rod

A high-voltage, anti-leakage technology, applied in the direction of electric/magnetic refining, electric/magnetic dehydration/emulsification, etc., can solve the problems of electrode cable breakdown, creepage ablation, etc., to prolong the service life, The effect of preventing breakdown and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

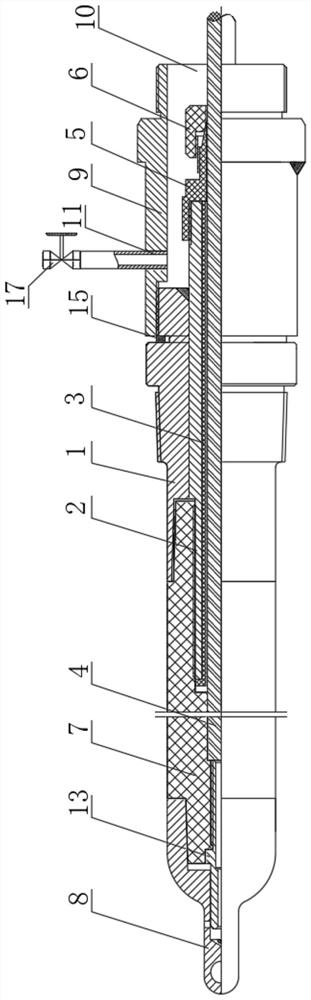

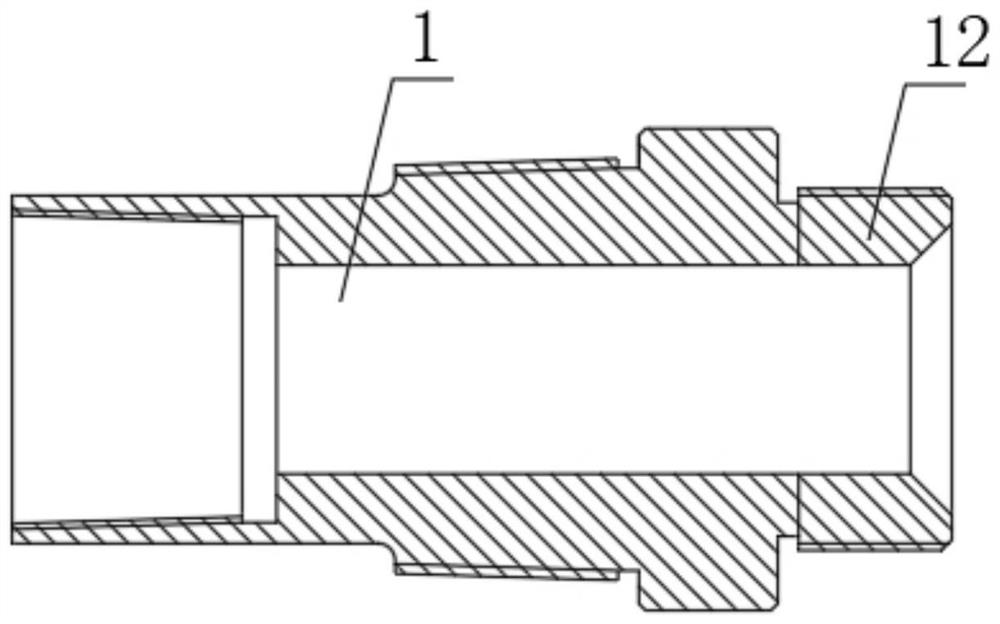

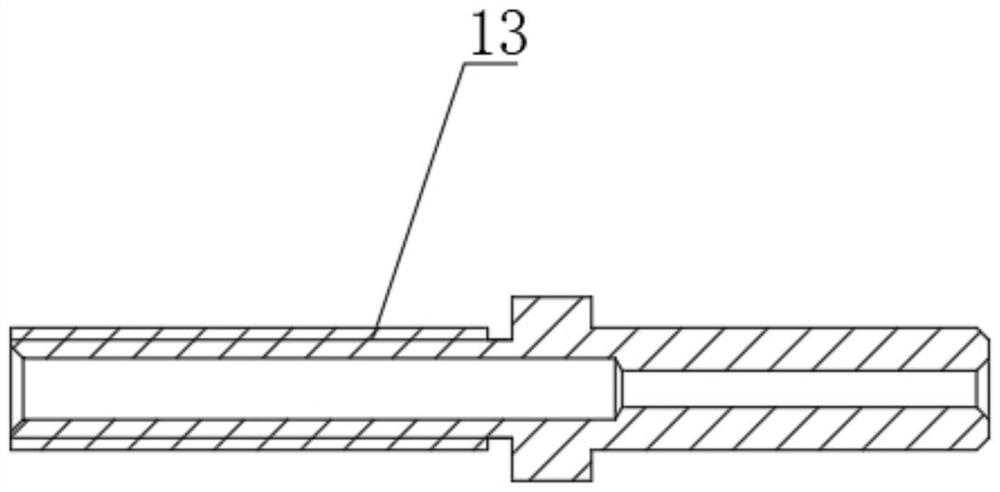

[0025] see Figure 1-Figure 8 , the present invention provides an anti-leakage high-voltage electric lead-in rod, including a joint seat 1 and an inner liner 2, the inner liner 2 is threadedly mounted on the inner side of the joint seat 1, and an inner bushing 3 is installed on the inner side of the inner liner 2, specifically When setting, in order to facilitate the connection with the inner bushing 3, the side of the inner bushing 3 is provided with an extension part 14 that cooperates with the inner lining 2. The extension part 14 is arranged in a circular shape, and is convenient for the cable 4 to pass through; The inner side of the bushing 3 is provided with a cable 4, one side of the inner bushing 3 is connected with a locking bolt 5, and the end of the locking bolt 5 is connected with a locking nut 6, and the cooperation of the locking bolt 5 and the locking nut 6, It is convenient to fasten the cable 4 and prevent it from being pulled off during use. One side of the j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com