Mould dumping gear for automatic plastics soaking equipment

A technology of flipping mechanism and mold, applied in coating and other directions, can solve the problems of high labor intensity and low production efficiency of workers, and achieve the effect of reducing labor intensity of workers, improving production efficiency and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention is described in further detail by the following examples.

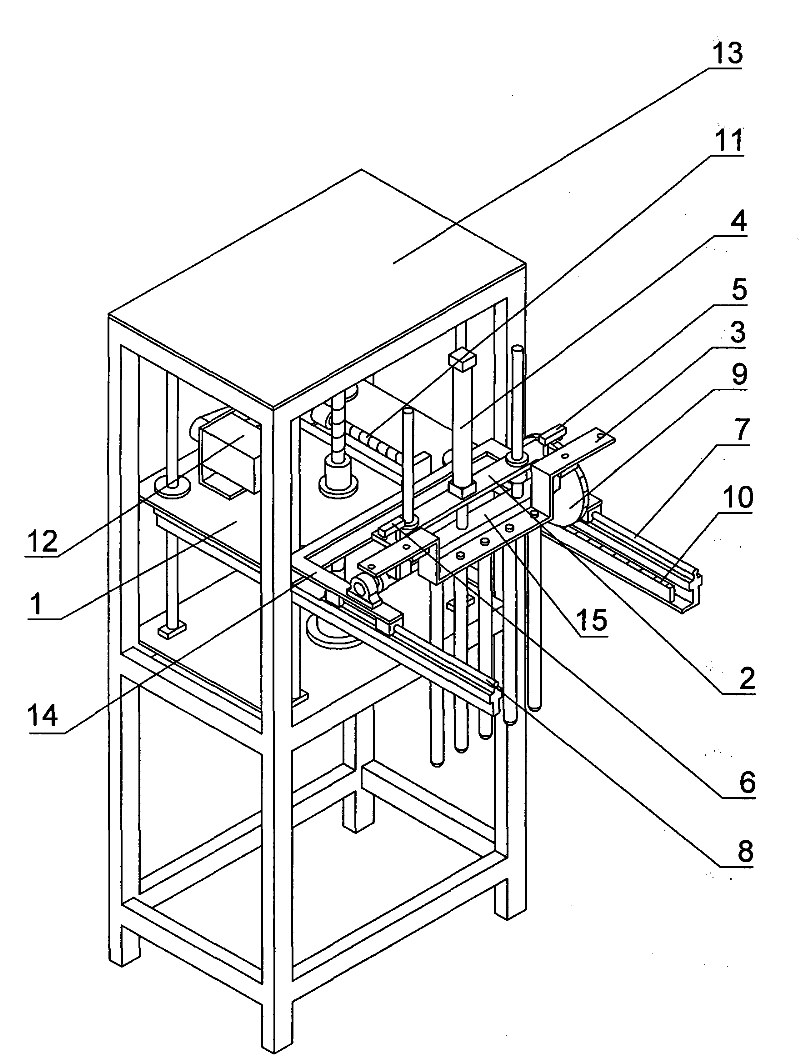

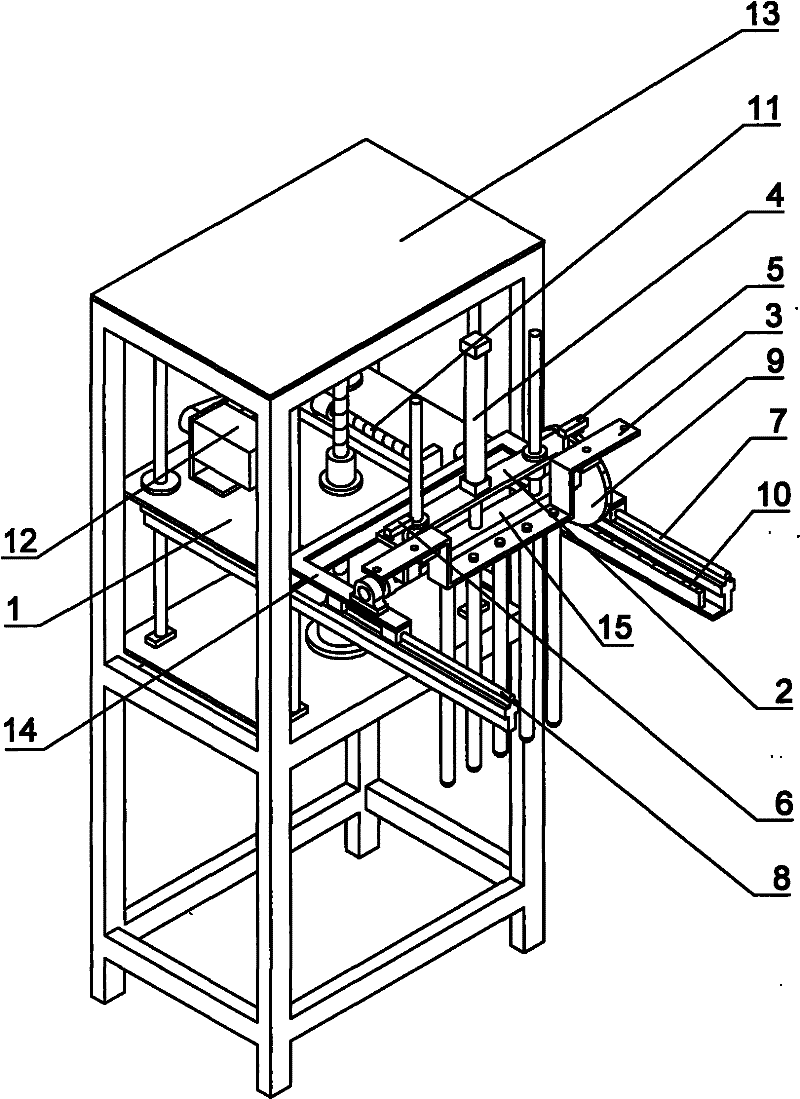

[0012] see figure 1 As shown, a mold turnover mechanism for automatic plastic dipping equipment consists of a lifter frame 13, a base plate 1, a first guide rail 7, a second guide rail 8, a guide rail seat 14, a mold plate 2, a mold 3, a lifting cylinder 4, The 1st rotary cylinder 5, the 2nd rotary cylinder 6, gear 9, rack 10, rotating shaft 15, upper and lower elevating mechanisms on the base plate, guide rail seat 14 front and rear motion drive mechanisms. One end of the first and second guide rails 7 and 8 is respectively connected to the same side of the base plate 1, the guide rail seat 14 is mounted on the first and second guide rails 7 and 8 and connected in a sliding manner, and the mold plate 2 is fixed on the Rail seat 14 both sides. The cross-section of the middle section of the rotating shaft 15 is rectangular, and the piston end of the lifting cylinder 4 installed in the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com