Electric iron with steam collection chamber

A technology for electric iron and steam collection, which is applied to hand irons, washing devices, textiles and papermaking, etc., can solve the problems of increasing energy consumption, affecting ironing, and high temperature, and achieves the effect of preventing dripping and solving dripping phenomenon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to clearly illustrate the solutions in the present invention, preferred embodiments are given below and detailed descriptions are given in conjunction with the accompanying drawings. The following description is merely exemplary in nature and is not intended to limit the application or uses of the present disclosure. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

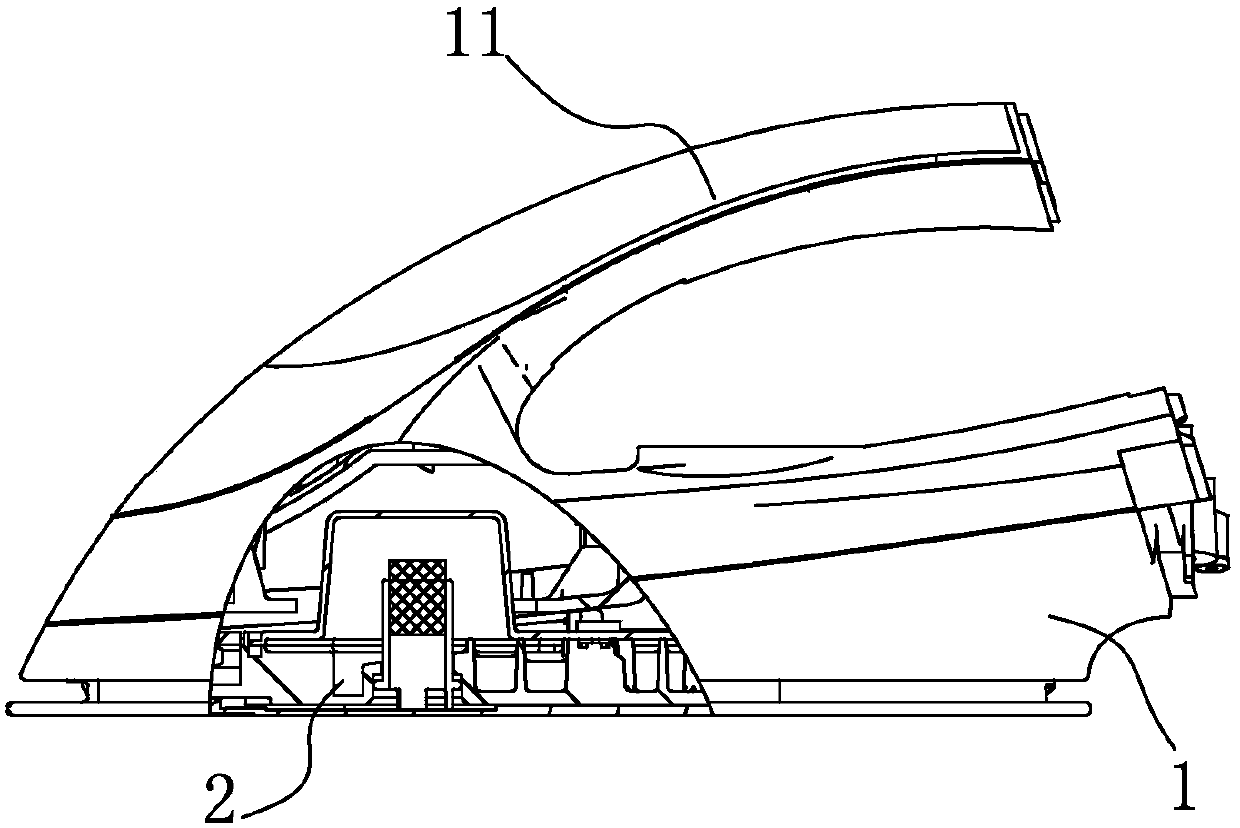

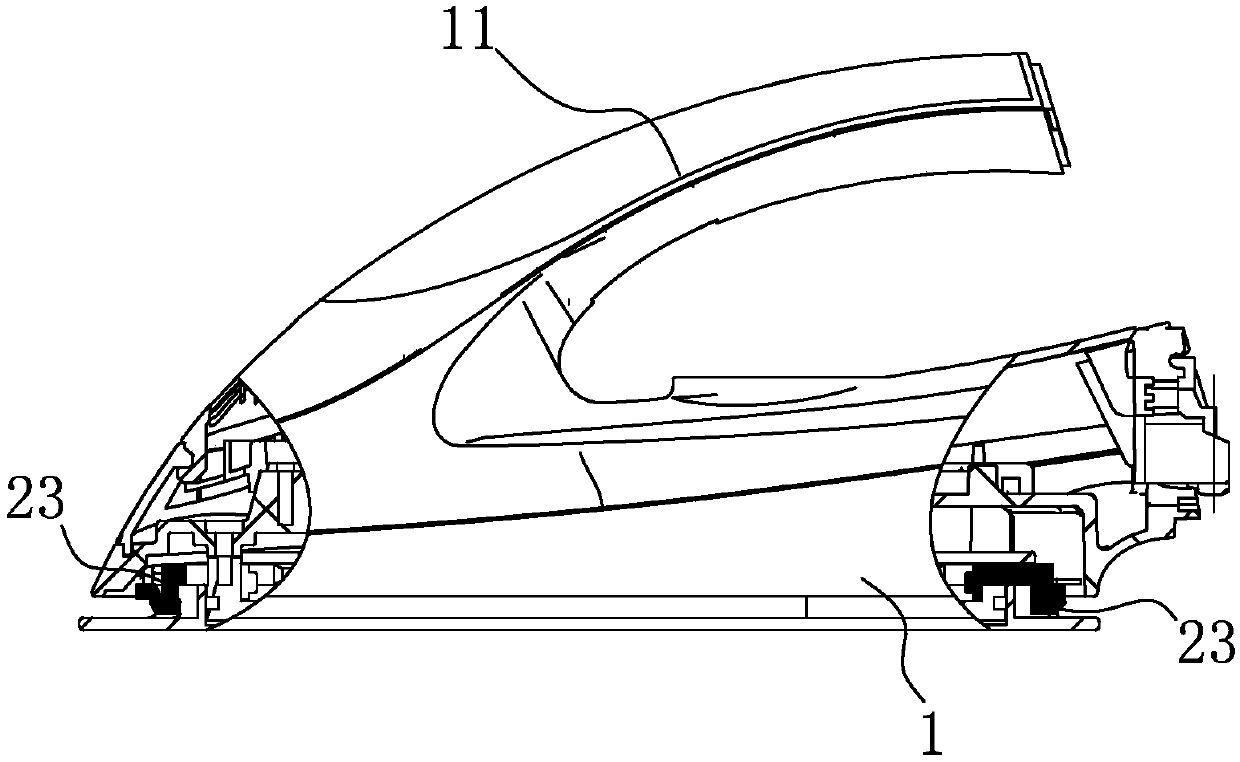

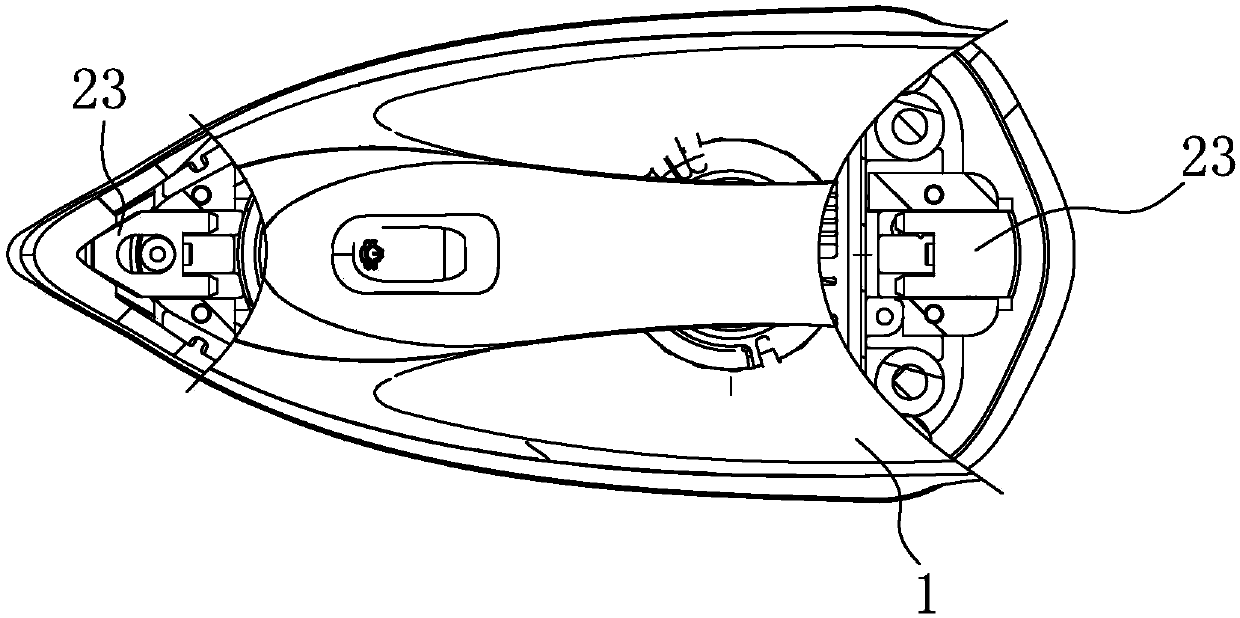

[0029] Such as Figure 1 to Figure 12 As shown, an electric iron with a steam collecting chamber provided by the present invention includes a casing 1 and a bottom plate 2 connected to the casing 1, a handle 11 is arranged on the casing 1, and the bottom plate 2 is provided with a vaporization chamber 25, the bottom plate 2 is also provided with a steam collection chamber 4, the steam collection chamber 4 communicates with the vaporization chamber 25, and the bottom of the steam collection chamber 4 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com