Vine tea beverage filling machine using electrostatic rectification to prevent airflow from blowing out output fluid

A filling machine and airflow technology, applied in the field of beverage filling, can solve the problems of dripping, no flow, stains, etc., and achieve the effect of assisting filling work and good filling work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

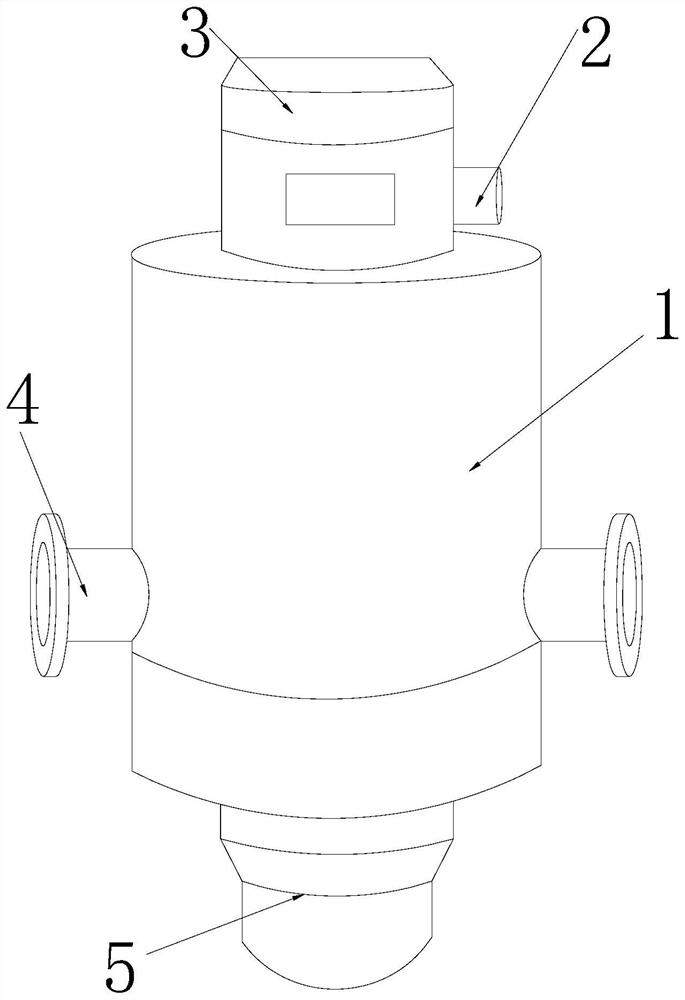

[0029] see figure 1 , the present invention provides a rattan tea beverage filling machine that utilizes electrostatic rectification to prevent the airflow from blowing away the output fluid. The loading device 5 is located inside the device housing 1 and is movably connected with the device housing 1. The output pipe 4 is arranged at the left and right ends of the device housing 1 and connected through the device housing 1. The power frame 3 is connected to the device housing 1. The shells 1 are perpendicular to each other and the embedded device shell 1 is movably connected with the movable filling device 5. The air pipe 2 is located on the right end face of the power frame 3 and is connected with the power frame 3 at the same time. The air pipe 2 is made of through-hole plastic The cylindrical structure of the through-hole type can not be blocked when the airflow enters through the through-hole cylindrical structure, so that it can output power better.

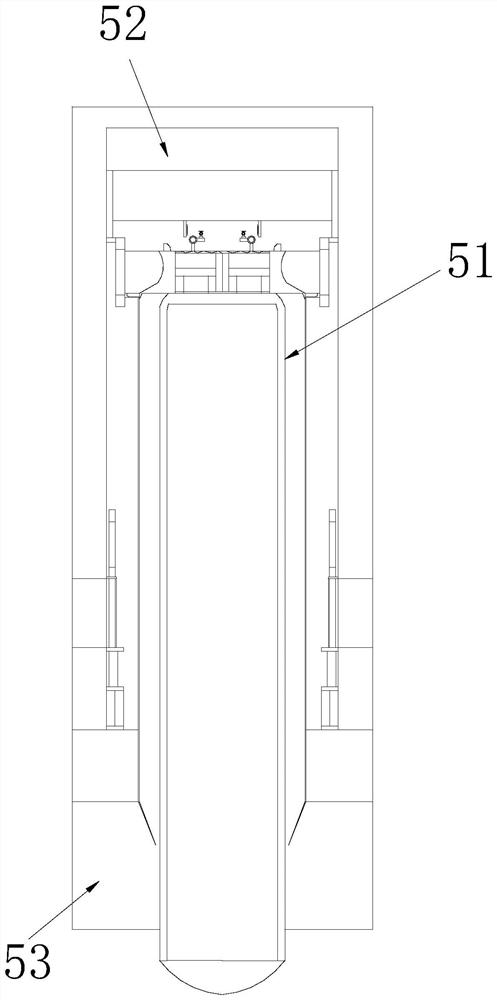

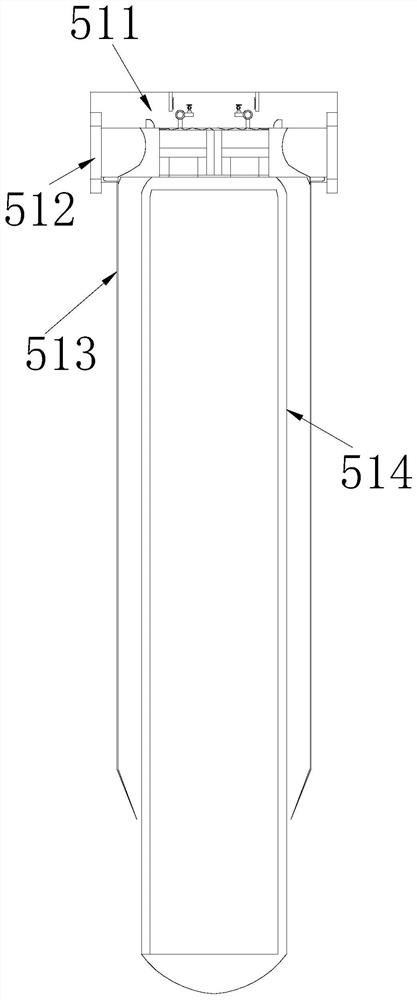

[0030] see figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com