Production process of halogen-free flame-retardant socket granules

A production process and socket technology, which is applied to the production process of halogen-free flame retardant socket pellets, can solve the problems of poor flame retardant application effect, etc., and achieve the effects of good processing fluidity, promotion of char formation, and prevention of molten droplets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

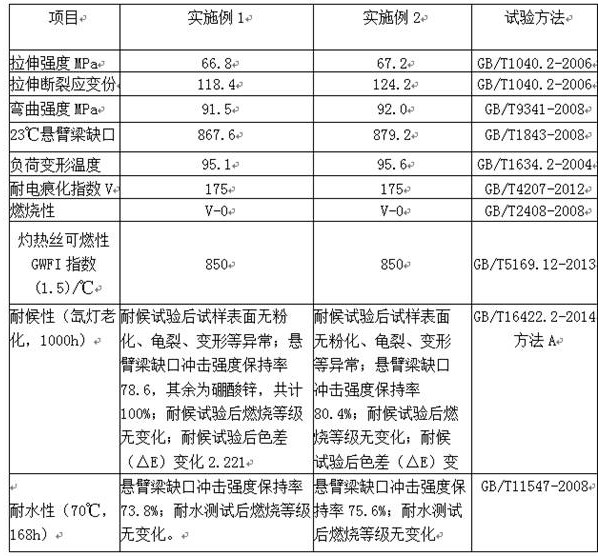

Embodiment 1

[0020] The first step is to weigh the following components according to parts by weight: 93 parts of LEXAN 101R PC polycarbonate resin, 1 part of Wacker SILRES604 phenyl methyl silicone resin, 1 part of phenyl phosphate, and phenyl phosphate is Suzhou Daba CR-741 bisphenol A bis(diphenyl phosphate), 0.5 part of titanium dioxide, 2 parts of AT-H841 phenolic resin sulfonate sodium salt, 0.5 part of light stabilizer, the light stabilizer is 2-(2 '-Hydroxyphenyl) benzotriazole UV-328, 0.5 part of ADDIMER 697 processing aid, 1.5 part of Dongzhuan ZB-2335 zinc borate; in the second step, the weighed materials are mixed evenly and dried at 100°C, The drying time is 4h; in the third step, the temperature of the first section of the extruder is 155℃, the temperature of the second section is 230℃, the temperature of the other sections is 235℃, the speed of the main machine is 200r / min, and the feeding frequency is 10r / min, extrusion blending and granulation: twin-screw extrusion granul...

Embodiment 2

[0022] The first step, weigh the following components according to weight percentage: 86 parts of LEXAN 101R PC polycarbonate resin, 0.5 part of Wacker SILRES604 phenyl methyl silicone resin, 5 parts of phenyl phosphate, the phenyl phosphate is Suzhou University Eight mixtures of CR-741 bisphenol A bis(diphenyl phosphate) and Lihai Petrochemical triphenyl phosphate by weight of 1:2, 1 part of Chuntai R103 titanium dioxide, 3.2 parts of Taixing HT-207 zinc borate, 4 parts of AT-H841 phenolic resin sulfonic acid sodium salt, 0.1 part of light stabilizer, the light stabilizer is 2-hydroxy-4-n-octyloxybenzophenone brand UV-531, 2-(2'-hydroxyphenyl ) 1:2 mixture of benzotriazole brand UV-328 by weight, 0.2 part of ADDIMER RC75 processing aid; the second step, the weighed material is mixed and dried at 110 ° C, drying time 5h; the third Step. The temperature of the first stage of Zhejiang Wutian Machinery extruder is 180 °C, the temperature of the second stage is 235 °C, the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com