Drip-proof connection head applied to water tap

An anti-drip, faucet technology, applied in the field of faucets, can solve the problems of high maintenance cost, only the faucet can be replaced, and the valve core is easy to wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

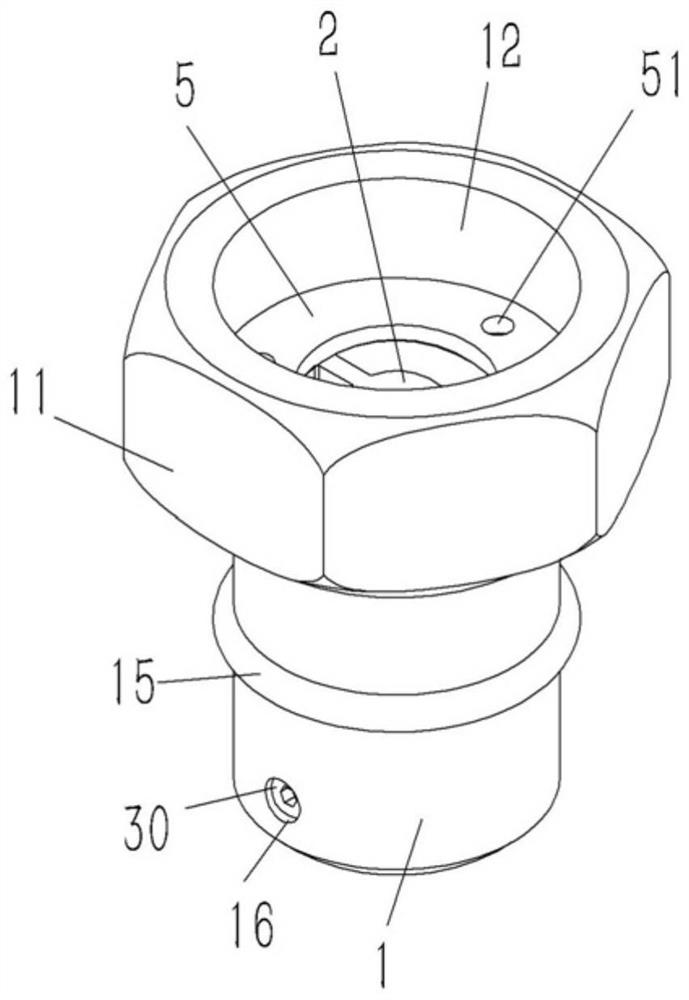

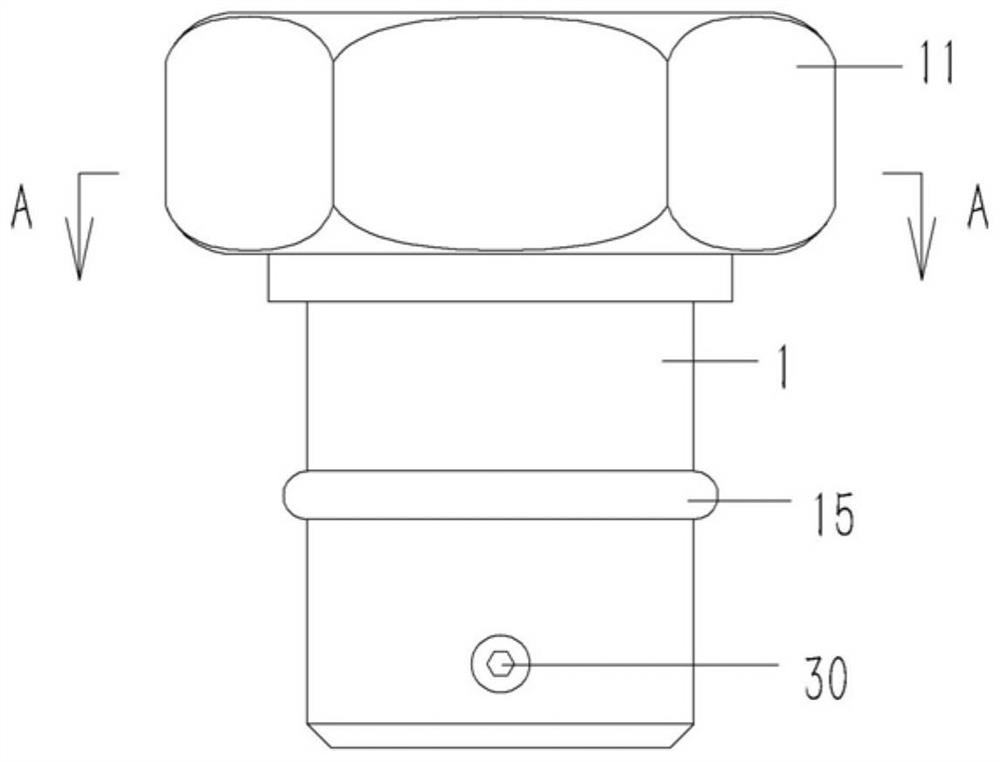

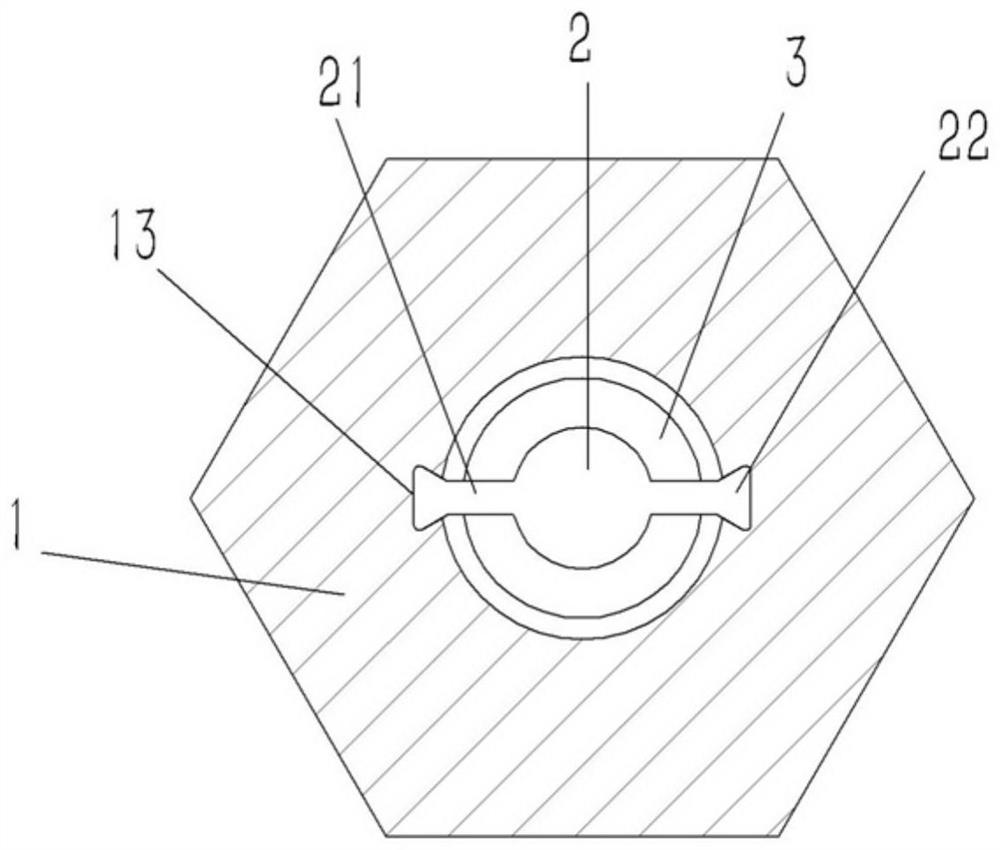

[0020] Example: see Figures 1 to 5 As shown, a drip-proof joint applied to a faucet includes a circular connecting pipe 1, a regular hexagonal knob head 11 is formed on the upper end of the connecting pipe 1, and a threaded hole communicating with the inner hole of the connecting pipe 1 is formed in the knob head 11. 12. A dovetail groove 13 penetrating through the bottom surface of the threaded hole 12 is formed on the inner wall opposite to the upper end of the connecting pipe 1, a circular impact plate 2 is inserted at the upper end of the connecting pipe 1, and spoke rods are formed on the outer walls on both sides opposite to the impact plate 2. 21. A dovetail-shaped guide block 22 is formed on the outer end of the spoke rod 21, and the guide block 22 is inserted into the dovetail groove 13 of the connecting pipe 1; a circular protruding ring 14 is formed on the inner wall of the connecting pipe 1 on the lower side of the dovetail groove 13, The middle part of the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com