Electric flange turner

A flanging machine, electric technology, applied in the direction of metal processing equipment, feeding devices, manufacturing tools, etc., can solve the problems of unreliable quality, falling off of pipes and flanges, high cost, etc., and achieve rapid mass production and uniform circumferential direction , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

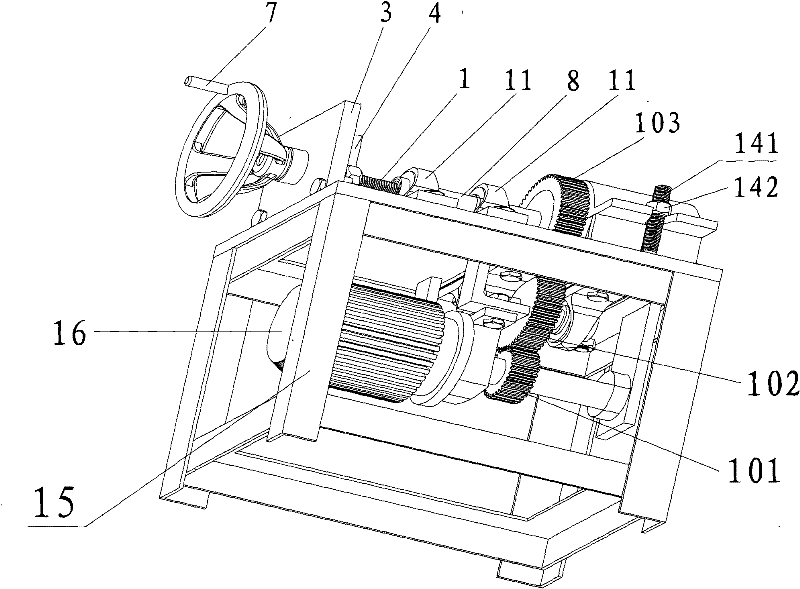

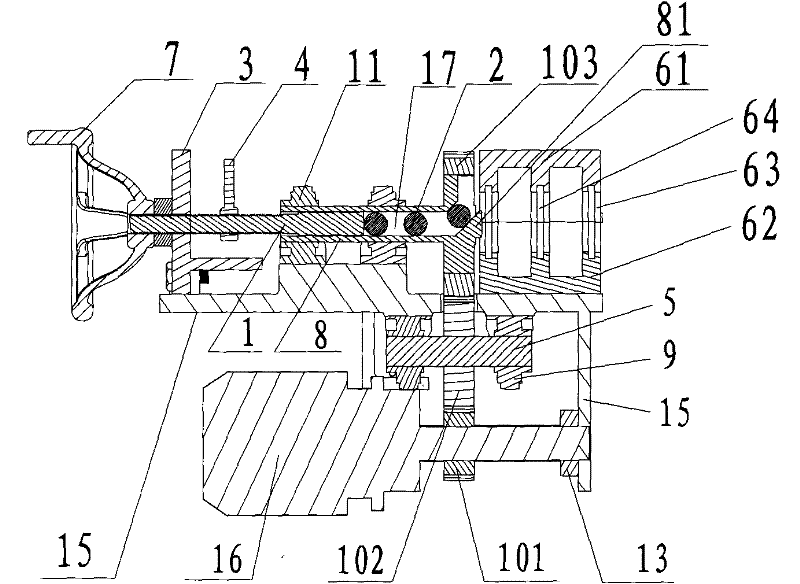

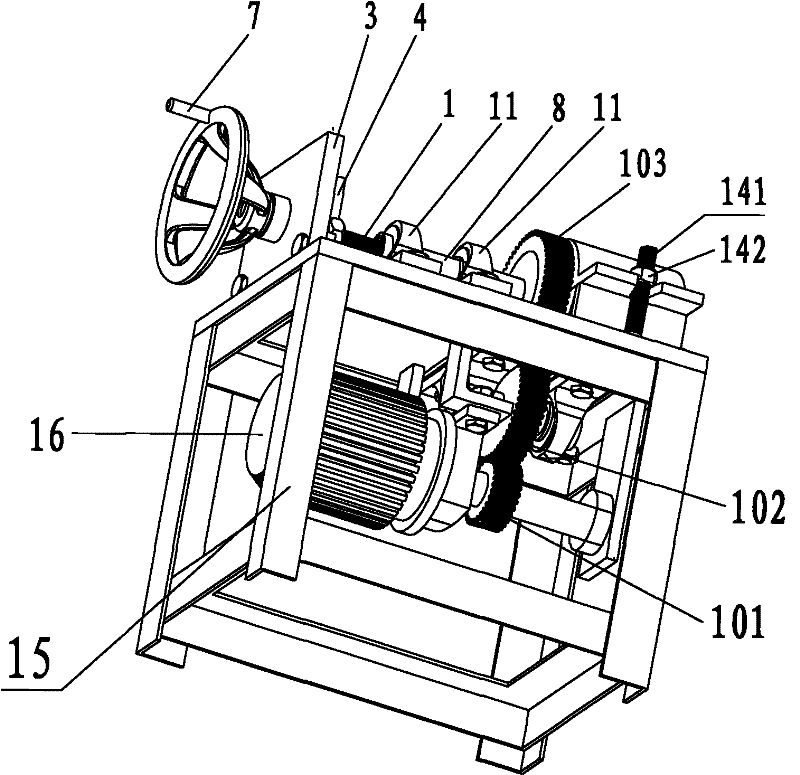

[0026] see figure 1 and 2 , the present invention is provided with frame 15, feeding device and clamp, and feeding device and clamp are located on frame 15.

[0027] Frame 15 is provided with 4 legs and table top, adopts angle steel to weld.

[0028] The feeding device is provided with a motor 16, a gear transmission mechanism, a rotating roller 8, flanging balls 2 (3 pieces) and a propelling rod 1. Motor 16 is installed on the frame 15, and the output shaft front end of motor 16 is supported on the frame 15 by bearing 13, and transmission mechanism is provided with first gear 101, second gear 102 and the 3rd gear 103, and first gear 101 and motor 16 The output shaft is connected, the first gear 101 meshes with the second gear 102, the gear shaft 5 of the second gear 102 is installed through the seat bearing 9, the second gear 102 meshes with the third gear 103, and the third gear 103 is sleeved on the rotating roller 8 on. The rotating roller 8 is installed on the frame 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com