Plastic pipe electric end bending machine

A technology of plastic pipe and edge bending machine, applied in the direction of tubular goods, other household appliances, household appliances, etc., can solve the problems of processing pipe length limitation, uneven welding, waste of energy, etc., to achieve rapid mass production, small equipment , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

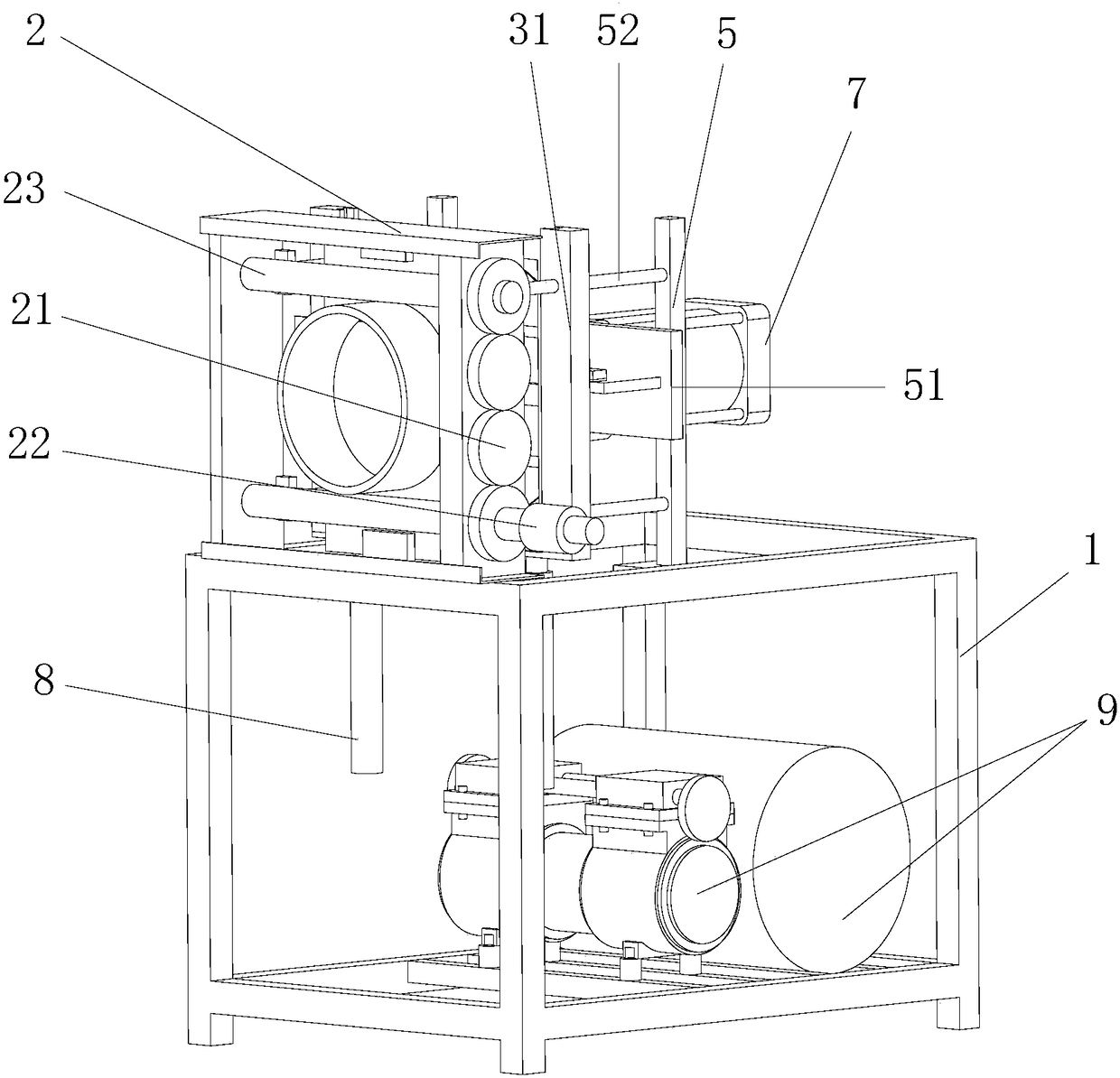

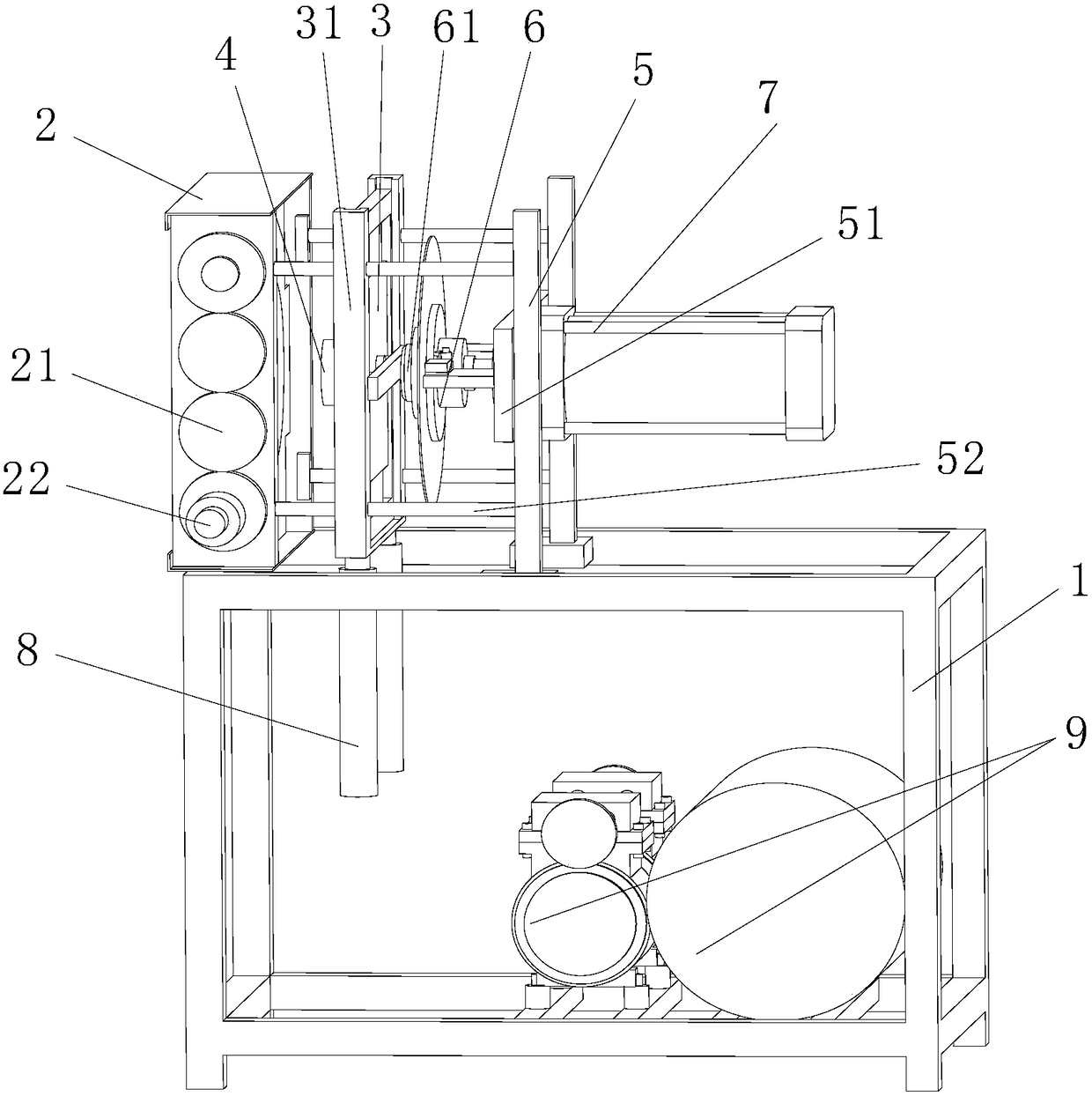

[0019] see figure 1 and 2 , the present embodiment is provided with machine base 1, fixture 2, heating plate 3, heating plate 4, slide rail device 5, extruded forming plate 6, first push-pull cylinder 7, second push-pull cylinder 8, air compressor 9 and cooling device .

[0020] The fixture 2 is installed on the machine base 1, the heating plate 4 and the heating plate 3 are arranged behind the fixture 2, the extruded forming plate 6 is arranged behind the heating plate 3, and the extruded forming plate 6 is provided with a lining head 61 and surrounding the lining head An annular groove for curved edge forming, the first push-pull cylinder 7 is installed on the base 1 through the slide rail device 5, the piston of the second push-pull cylinder 8 is connected with the bottom of the heating plate 3, the piston of the first push-pull cylinder 7 is connected with the bottom of the heating plate 3 The rear end of the extruded disk 6 is connected, and the extruded disk 6 is slida...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com