A high chromium roll spray quenching process

A technology of spray quenching and processing technology, which is applied in the direction of quenching devices, manufacturing tools, furnace types, etc., to achieve good quenching effect and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

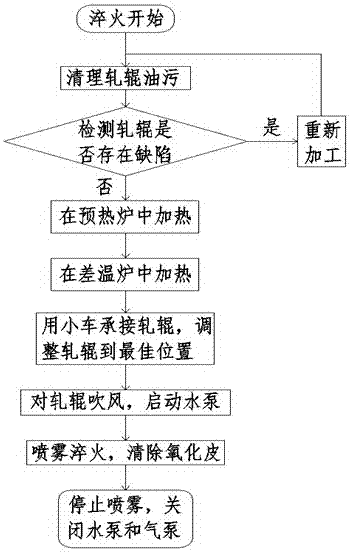

[0033] A high chromium roll quenching method, comprising the following steps,

[0034] Step A, cleaning the roll surface of the roll, cleaning the oil stain on the roll surface of the roll;

[0035] Step B, checking the roll surface defects, checking whether there are casting defects on the roll surface and the end surface of the rolls, reprocessing the rolls with casting defects, and performing heat treatment on the rolls without casting defects. Casting defects include sand holes, pores, slag inclusions, cracks, bumps, and scratches.

[0036] Step C, heat treatment of the rolls in the furnace, first preheat the rolls in the preheating furnace, the preheating time is 57 hours, the preheating temperature is 510 °C, after the preheating is completed, transfer the rolls to the differential temperature furnace for temperature difference Heating, the heating time is 2.5 hours, and the heating temperature is 850°C. After the heating is completed, the rolls are released from the fu...

Embodiment 2

[0040] A high chromium roll quenching method, comprising the following steps,

[0041] Step A, cleaning the roll surface of the roll, cleaning the oil stain on the roll surface of the roll;

[0042] Step B, checking the roll surface defects, checking whether there are casting defects on the roll surface and the end surface of the rolls, reprocessing the rolls with casting defects, and performing heat treatment on the rolls without casting defects. Casting defects include sand holes, pores, slag inclusions, cracks, bumps, and scratches.

[0043] Step C, heat treatment of the rolls in the furnace, first preheat the rolls in the preheating furnace, the preheating time is 63 hours, the preheating temperature is 590 °C, after the preheating is completed, transfer the rolls to the differential temperature furnace for temperature difference Heating, the heating time is 2.3 hours, and the heating temperature is 1000°C. After the heating is completed, the rolls are released from the f...

Embodiment 3

[0047] A high chromium roll quenching method, comprising the following steps,

[0048] Step A, cleaning the roll surface of the roll, cleaning the oil stain on the roll surface of the roll;

[0049] Step B, checking the roll surface defects, checking whether there are casting defects on the roll surface and the end surface of the rolls, reprocessing the rolls with casting defects, and performing heat treatment on the rolls without casting defects. Casting defects include sand holes, pores, slag inclusions, cracks, bumps, and scratches.

[0050] Step C, heat treatment of the roll in the furnace, first preheat the roll in the preheating furnace, the preheating time is 60 hours, the preheating temperature is 550 °C, after the preheating is completed, transfer the roll to the differential temperature furnace for temperature difference Heating, the heating time is 3 hours, and the heating temperature is 900°C. After the heating is completed, the rolls are released from the furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com