Household appliances shell and injection moulding method thereof

A technology for injection molding and household appliances, which is applied to electrical equipment shells/cabinets/drawers, household appliances, household components, etc. It can solve the problems of high cost of mold development, high technical threshold, and large capital demand for two-color injection molding, and reach the market. The effect of low risk, low technical threshold and low capital investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention are described in detail below in conjunction with accompanying drawings:

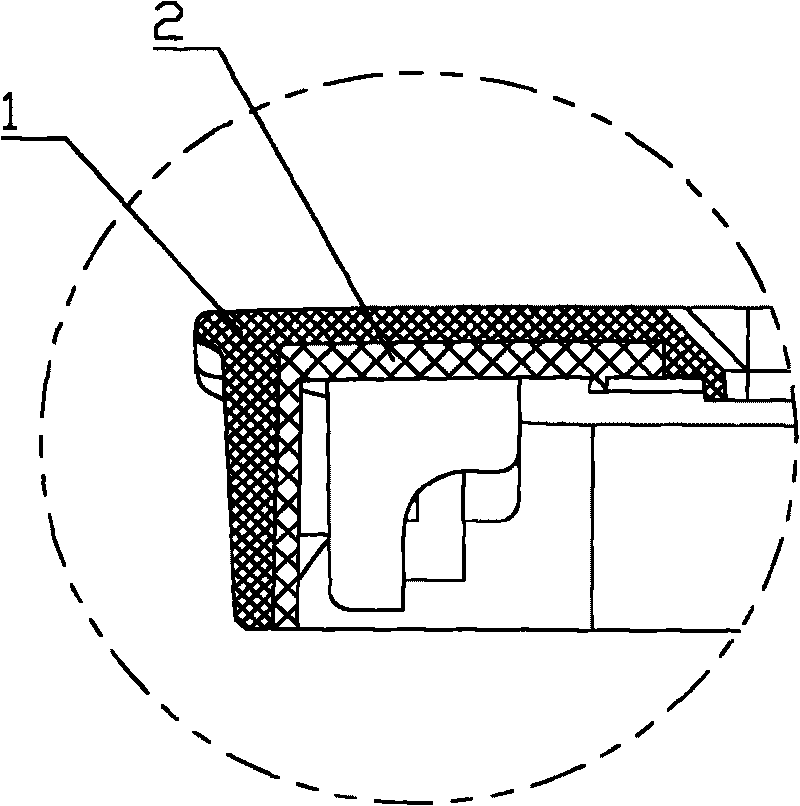

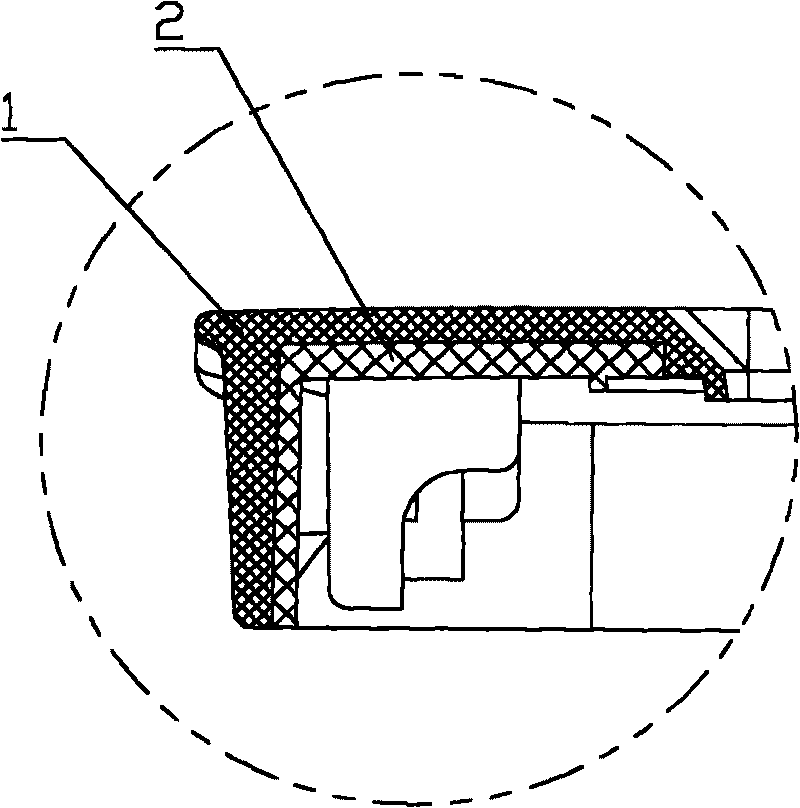

[0021] Such as figure 1 As shown, a casing of a household appliance, the casing includes a first layer 1 of the casing and a second layer 2 of the casing, wherein the first layer 1 of the casing is a transparent layer, the second layer 2 of the casing is a translucent layer, and the casing The first layer 1 and the second layer 2 of the casing are successively solidified and integrally injection molded. In this embodiment, the first layer 1 of the casing is the outer layer, and the second layer 2 of the casing is the inner layer.

[0022] The injection molding method of the foregoing shell comprises the steps:

[0023] A. Inject the first layer 1 of the shell in the first set of molds; B. Take out the first layer 1 of the shell from the first set of molds and put it into the cavity of the second set of molds; C. The second shell layer 2 is injected into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com