Ecological bag reinforced retaining wall

A technology of ecological bags and retaining walls, applied in the field of retaining walls, can solve problems such as displacement, deformation and falling off, and structural instability of retaining walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

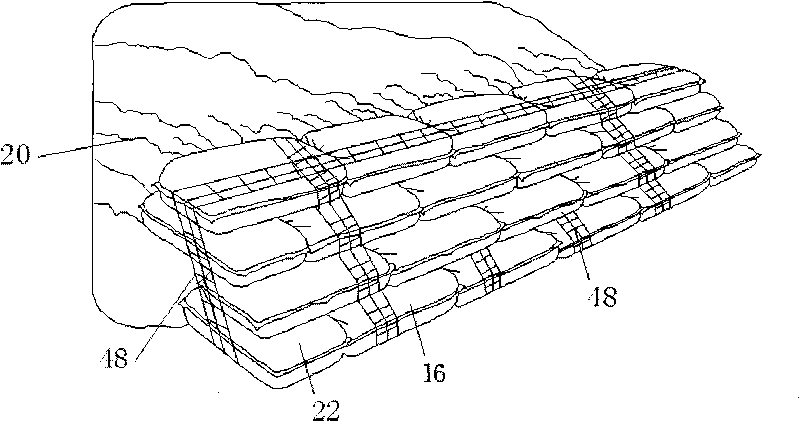

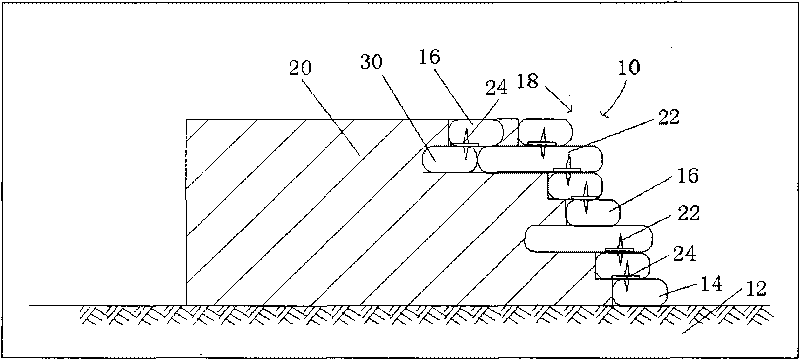

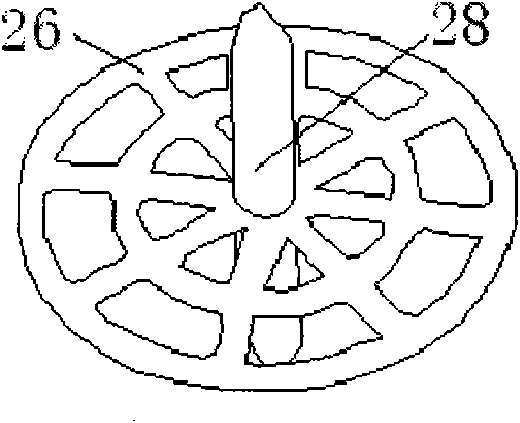

[0039] Such as figure 1 A perspective view of the stiffened retaining wall structure 10 of the present invention, figure 2 As shown in the sectional view of the stiffened retaining wall, the body of wall 18 of the stiffened retaining wall of the present invention is close to the filling material 20, including multi-layer ecological bags 16 stacked upwards from the ground 12 to connect adjacent ecological bags 16 disc connection buckle 24, and along the vertical direction and horizontal direction binding or / and the reinforcement grid 48 of weaving ecological bag. The ecological bag is best made of materials with strong corrosion resistance, anti-aging, non-toxic, and reusable materials, which can save resources and reduce environmental pollution at the same time. Connecting buckle 24 connects adjacent ecological bags 16, so that the whole retaining wall forms a whole, and the retaining wall body of wall can be built into vertical (not shown in the figure) as required or have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com