A method for non-destructive testing of bolt working load using low-frequency guided waves

A technology of working load and non-destructive testing, which is applied in the direction of measuring force, measuring devices, instruments, etc., to achieve the effects of strong operability, low testing cost and high testing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

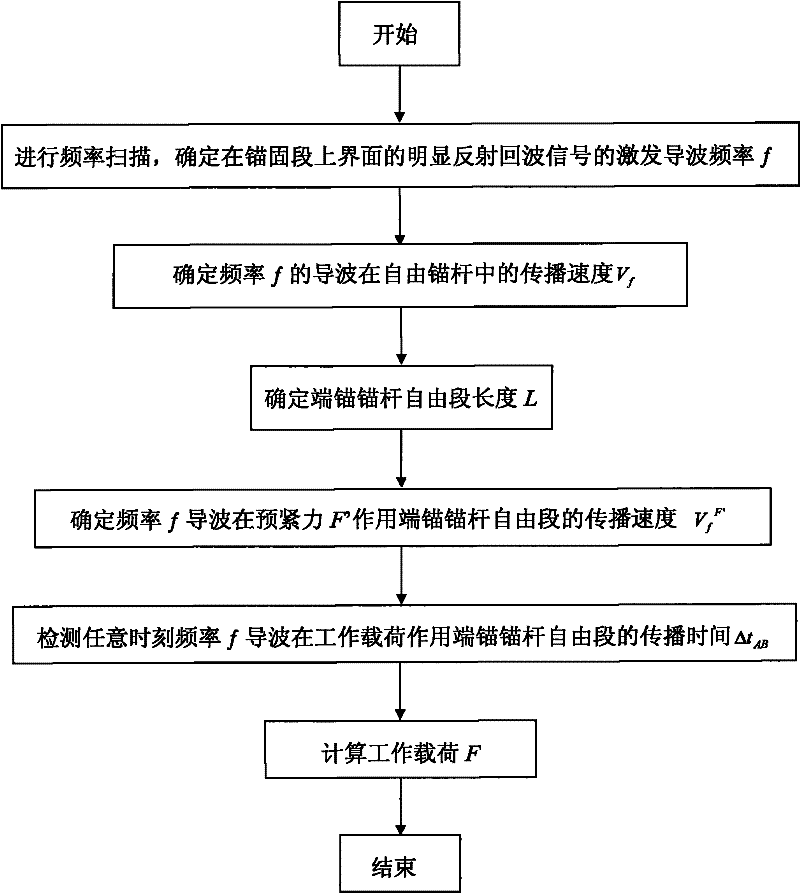

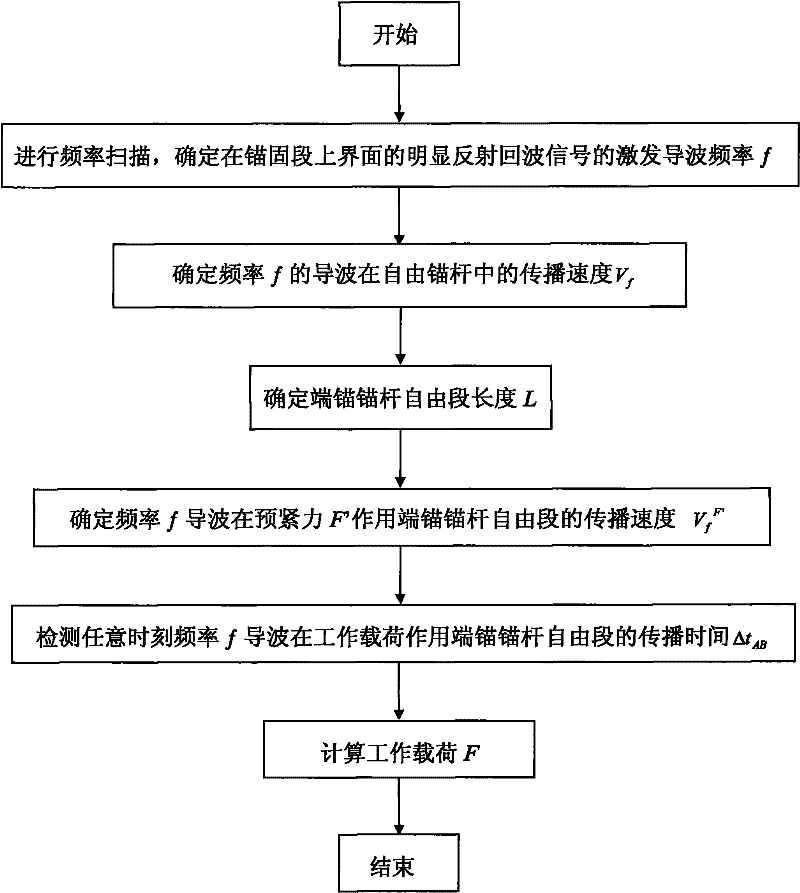

Method used

Image

Examples

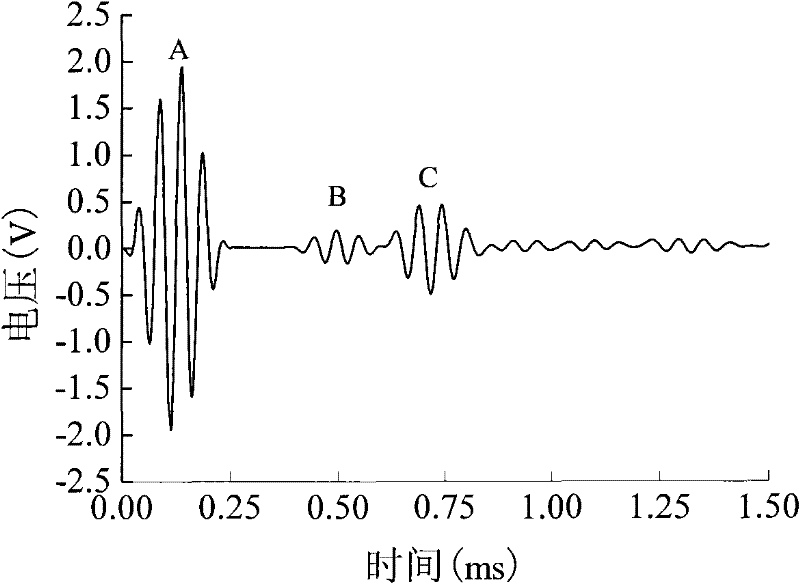

Embodiment 1

[0042] Using a guided wave with a frequency of 50kHz to detect a free bolt, the measured V f =5010.4m / s, according to step 3, the frequency of 50kHz guided wave is measured at the propagation time t=3.992e-4s of the free section of the end anchor and bolt without working load, and then the length of the free section of the end anchor and bolt is determined L= 1m. Apply a preloading force F'=40kN to the anchorage bolt to be tested, and the propagation time Δt of the guided wave at the free section of the anchorage bolt at the end of the preloading force AB '=3.995e-4s, then the propagation velocity V of the guided wave at the free section of the anchor bolt at the end of the pretightening force is obtained by step 4 f F '=5008.8m / s. Measure the time Δt of the guided wave propagating in the free section of the anchor bolt under the action of the working load F AB =4.001e-4, the working load F=100.628kN is calculated from step five, and the actual value of the working load is ...

Embodiment 2

[0044] Using a guided wave with a frequency of 60kHz to detect a free bolt, the measured V f =4936m / s, according to step 3, the propagation time t=4.051e-4s of the guided wave with a frequency of 60kHz in the free section of the end anchor bolt without working load is determined, and then the length of the free section of the end anchor bolt L=1m is determined . Apply a preloading force F'=40kN to the anchorage bolt to be tested, and the propagation time Δt of the guided wave at the free section of the anchorage bolt at the end of the preloading force AB '=4.055e-4s, then the propagation velocity V of the guided wave at the free section of the anchor bolt at the end of the pretightening force is obtained by step 4 f F '=4934.4m / s. Measure the time Δt of the guided wave propagating in the free section of the anchor bolt under the action of the working load F AB=4.0615e-4s, the working load F=102.2kN is obtained from step 5, and the actual value of the working load is 100kN,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com