Parallel mechanism with three-dimensional translation and one-dimensional rotation

A three-dimensional translation and parallel technology, applied in the field of robots, to achieve the effect of clear movement mode, improved rigidity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

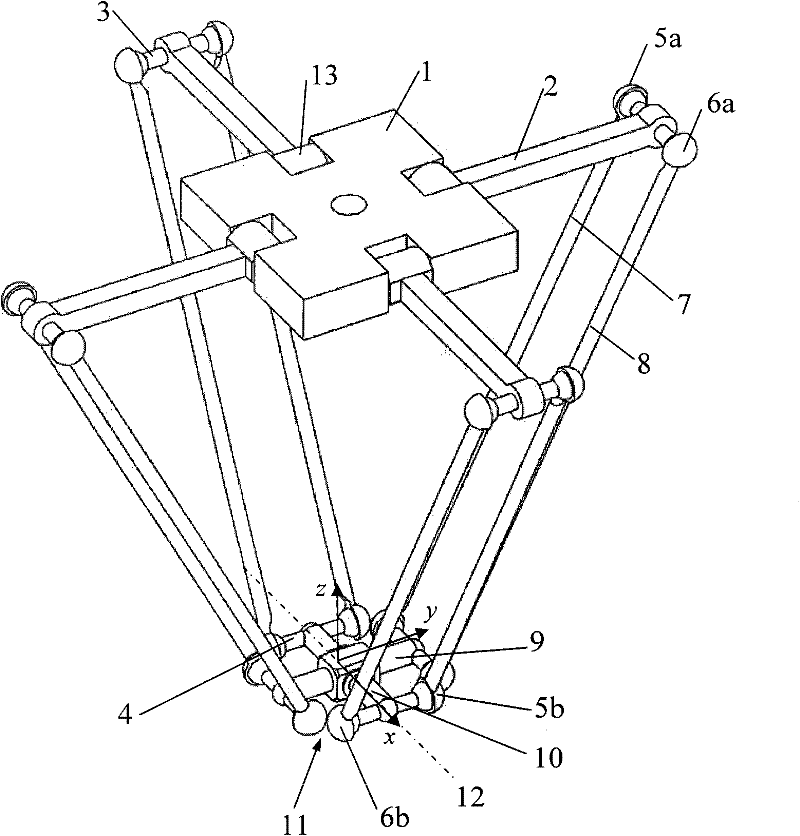

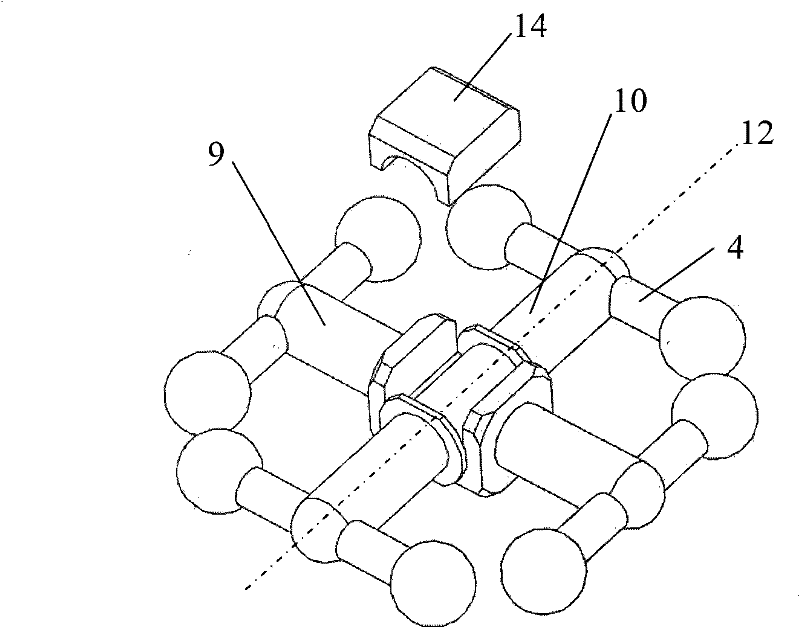

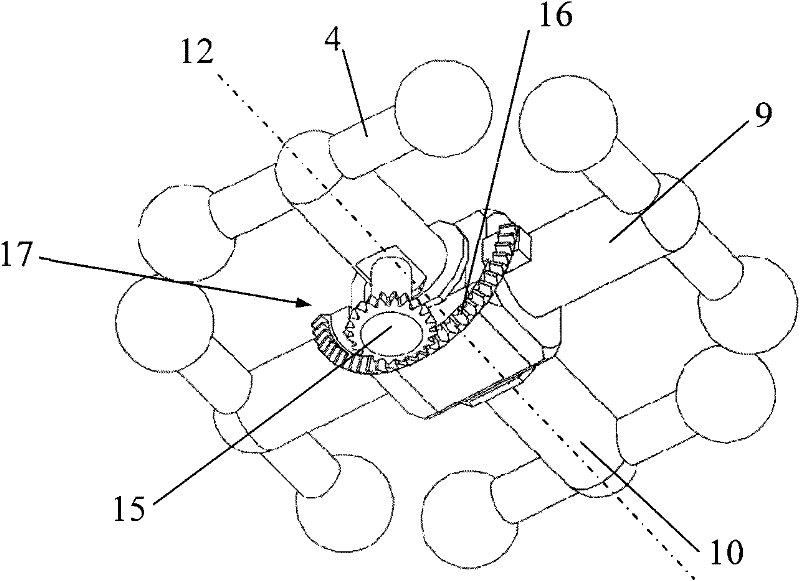

[0016] see Figure 1 ~ Figure 2 , a parallel mechanism with three-dimensional translation and one-dimensional rotation in the present invention, comprising a fixed frame 1, a moving platform 11, and four branch chains with the same structure symmetrically arranged between the fixed frame 1 and the moving platform 11; each The branch chain is composed of the near frame bar 2, the far frame bar I 7, the far frame bar II 8 and the upper connecting shaft 3 connecting the near frame bar 2 and the far frame bar I 7 and the far frame bar II 8. One end of the near frame rod 2 is affixed to the driving end 13 of the fixed frame 1, and the other end is affixed to the upper connecting shaft 3; the far frame rod I 7 and the far frame rod II 8 are arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com