Patents

Literature

38results about How to "The movement method is clear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

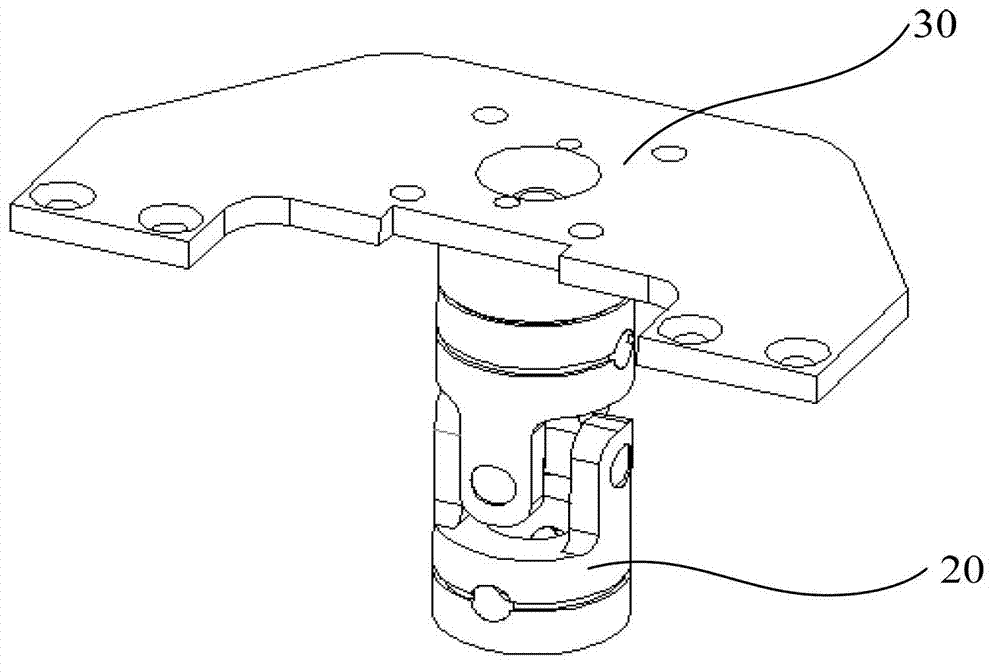

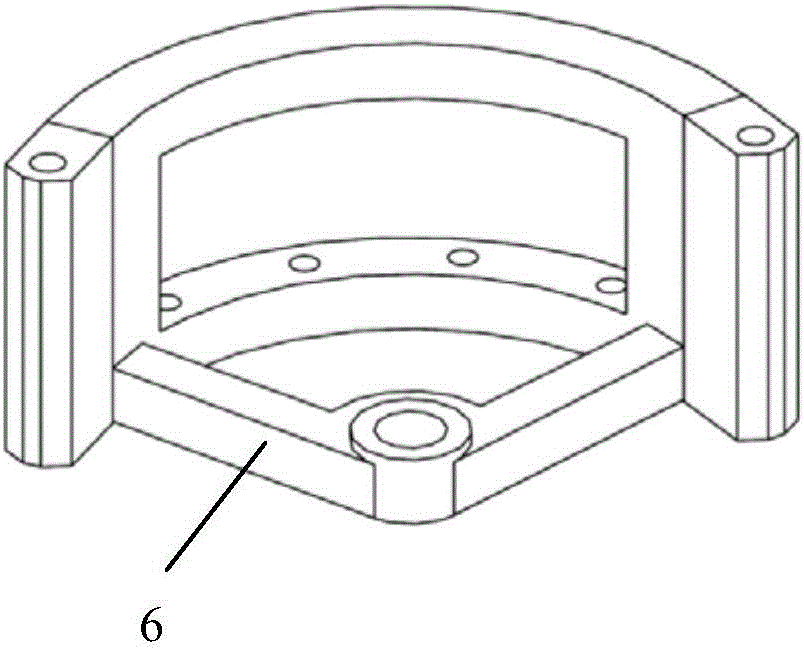

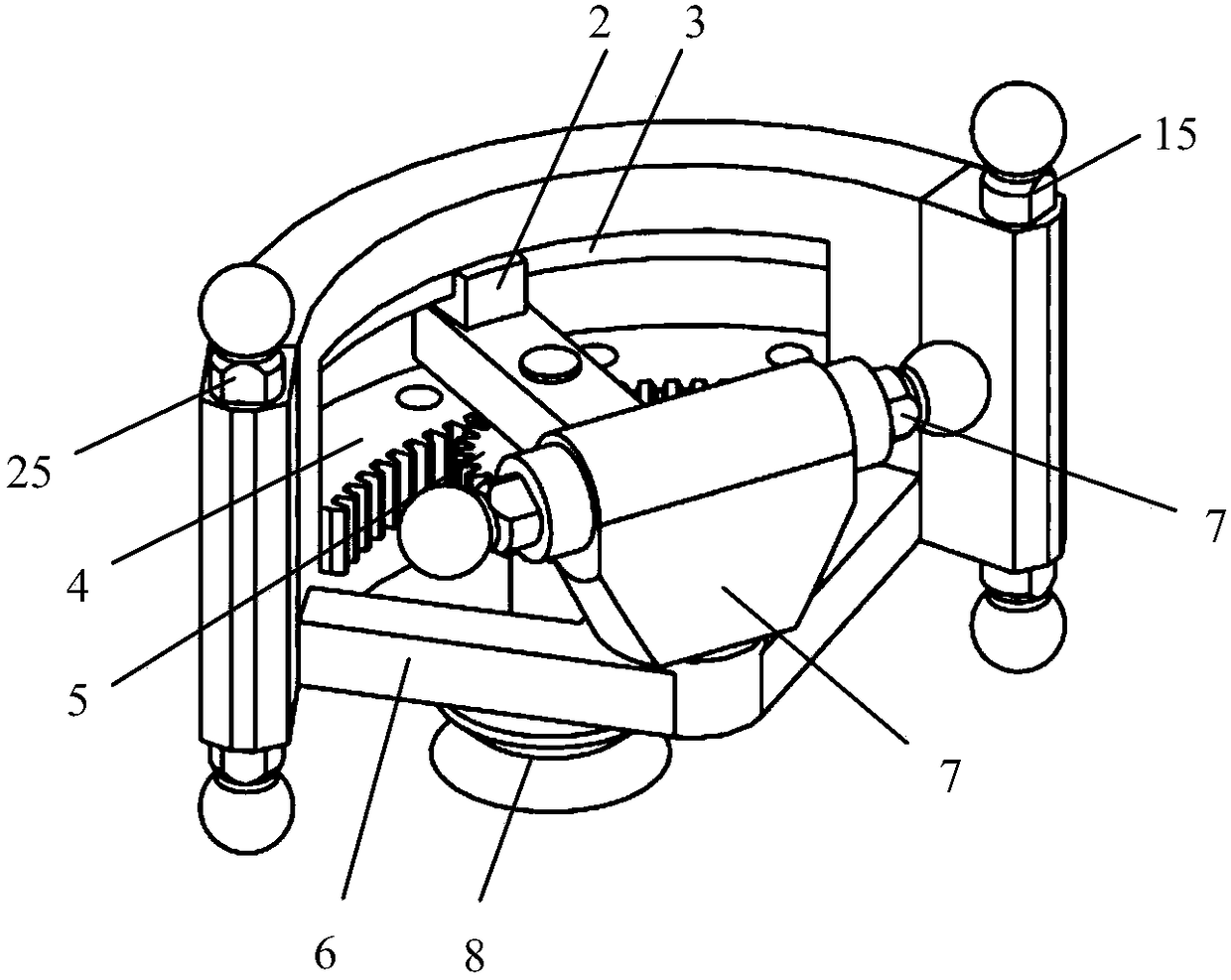

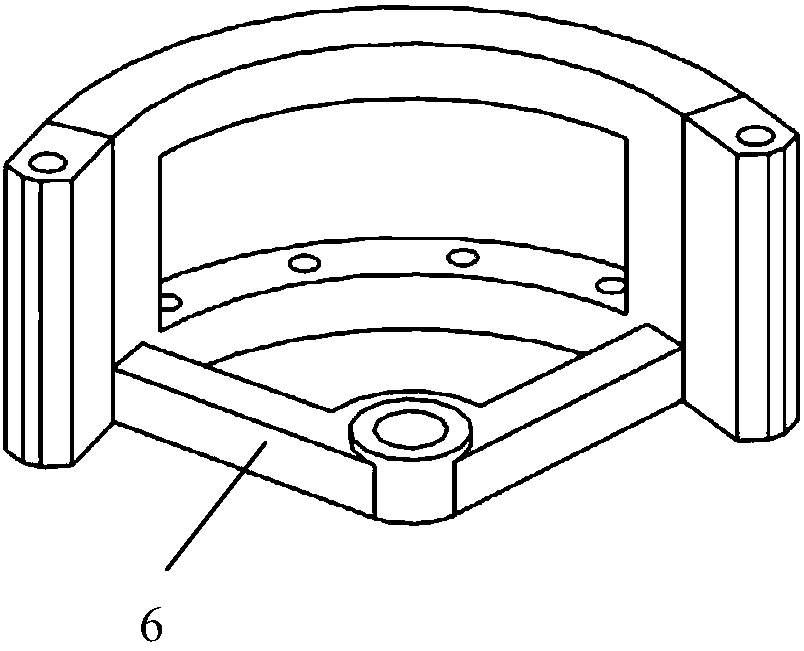

Parallel mechanism with three-dimensional translation and one-dimensional rotation

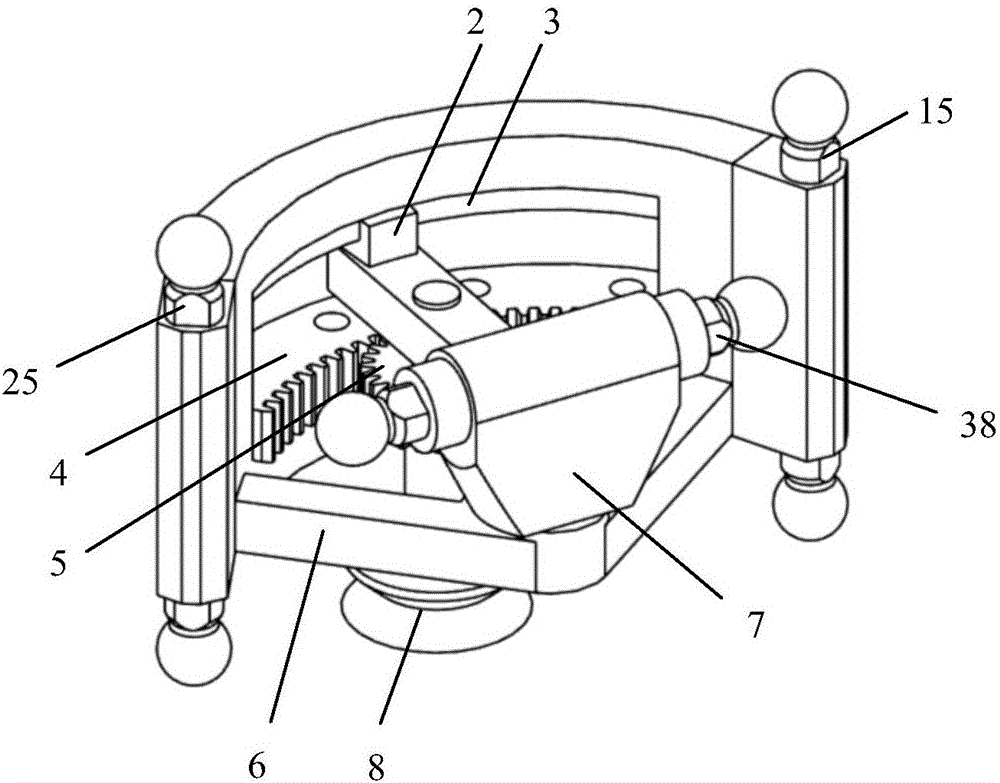

InactiveCN102069497AIncrease stiffnessImprove stabilityProgramme-controlled manipulatorEngineeringMechanical engineering

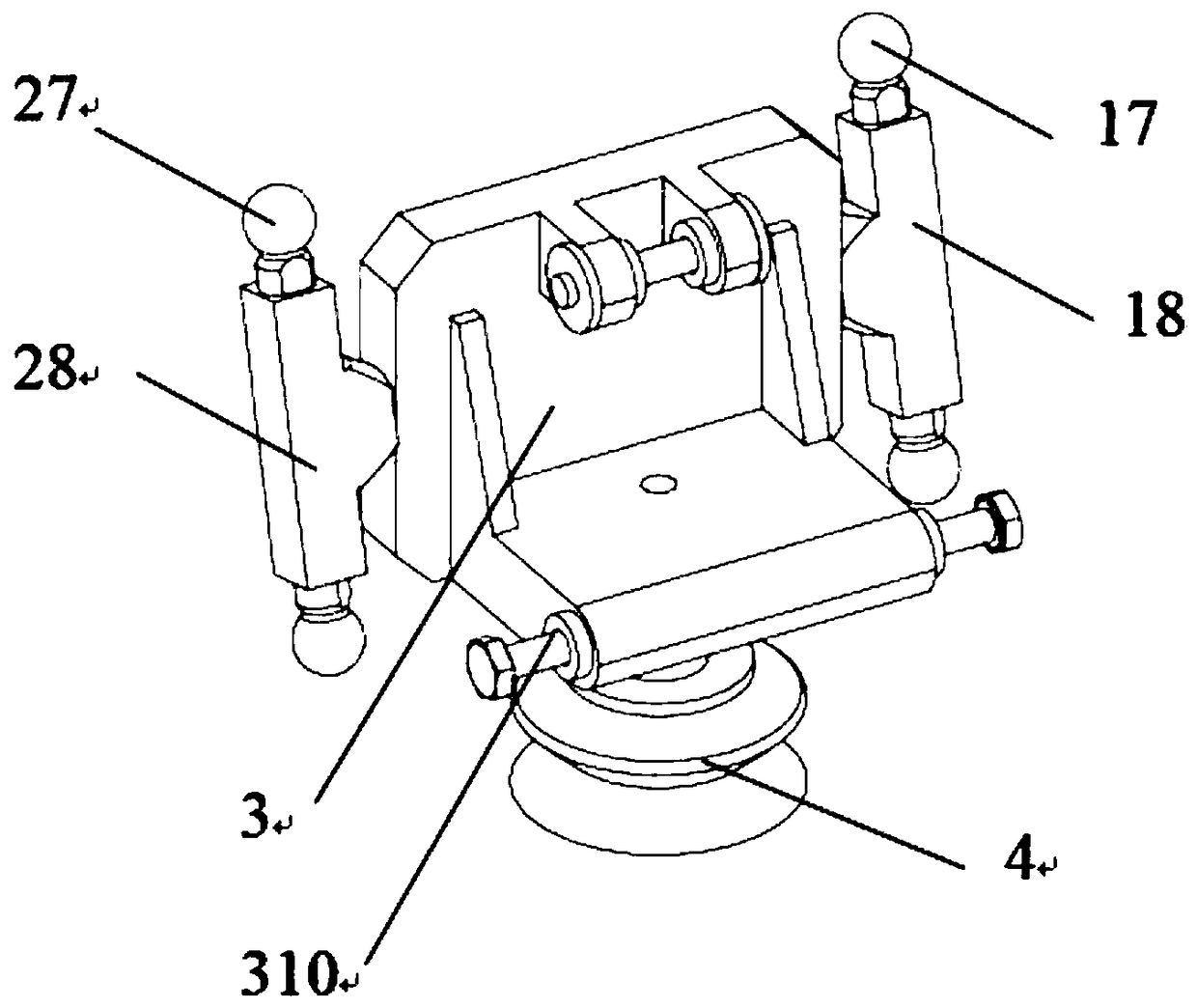

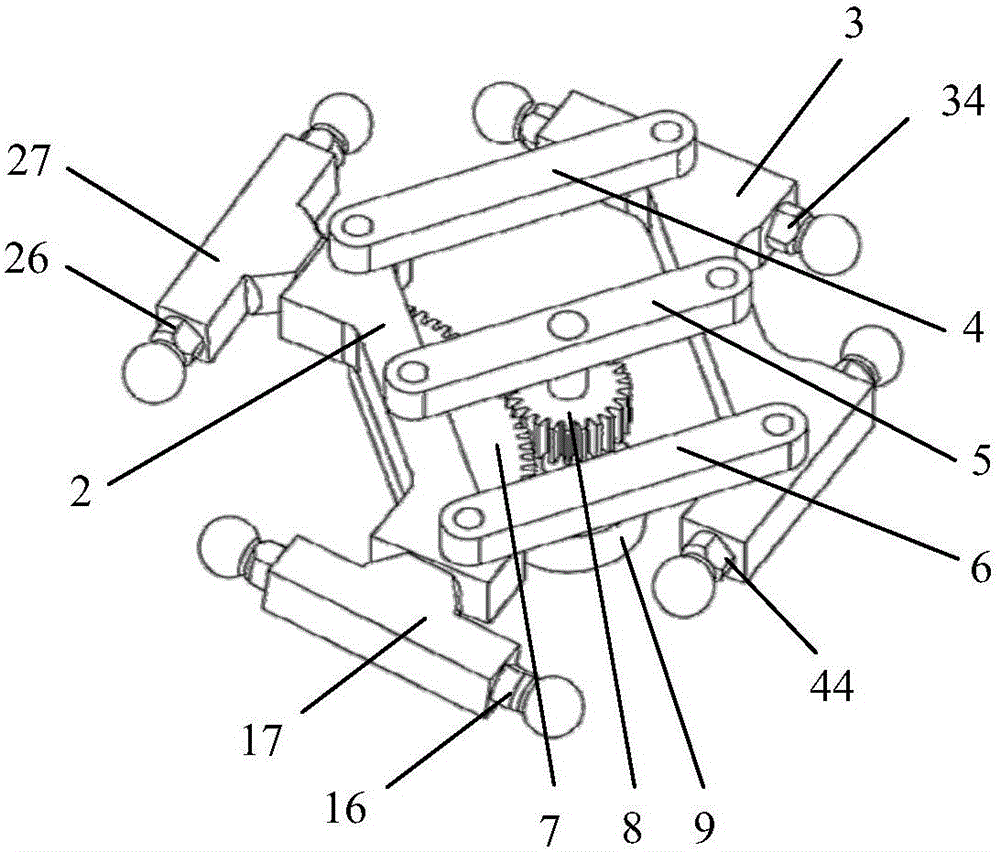

The invention discloses a parallel mechanism with three-dimensional translation and one-dimensional rotation, which comprises a fixed mount, a moving platform and four branched chains which are symmetrically arranged between the fixed mount and the moving platform and have same structures, wherein the moving platform comprises a main platform and a secondary platform which are horizontally arranged on the same centre line; the main platform is a closed structure; the secondary platform is embedded into the main platform; the main platform and the secondary platform are connected through a rotating mechanism; the rotating mechanism comprises a nut which is fixedly connected with the secondary platform and a screw which is rotatablely connected with the main platform through a bearing; the nut and the screw form a screw pair; the centre line of the screw is coincident with the vertical axis of the moving platform; the main platform is fixedly connected with a guide rod; and the secondary platform is glidingly connected with the guide rod. The parallel mechanism has a compact structure and high rigidity and stability; a guide mechanism and the rotating mechanism are designed light, thereby, the motion quality is reduced, high-speed capture is easy to realize and the requirements of the complicated capture and release operations are met.

Owner:TIANJIN UNIV

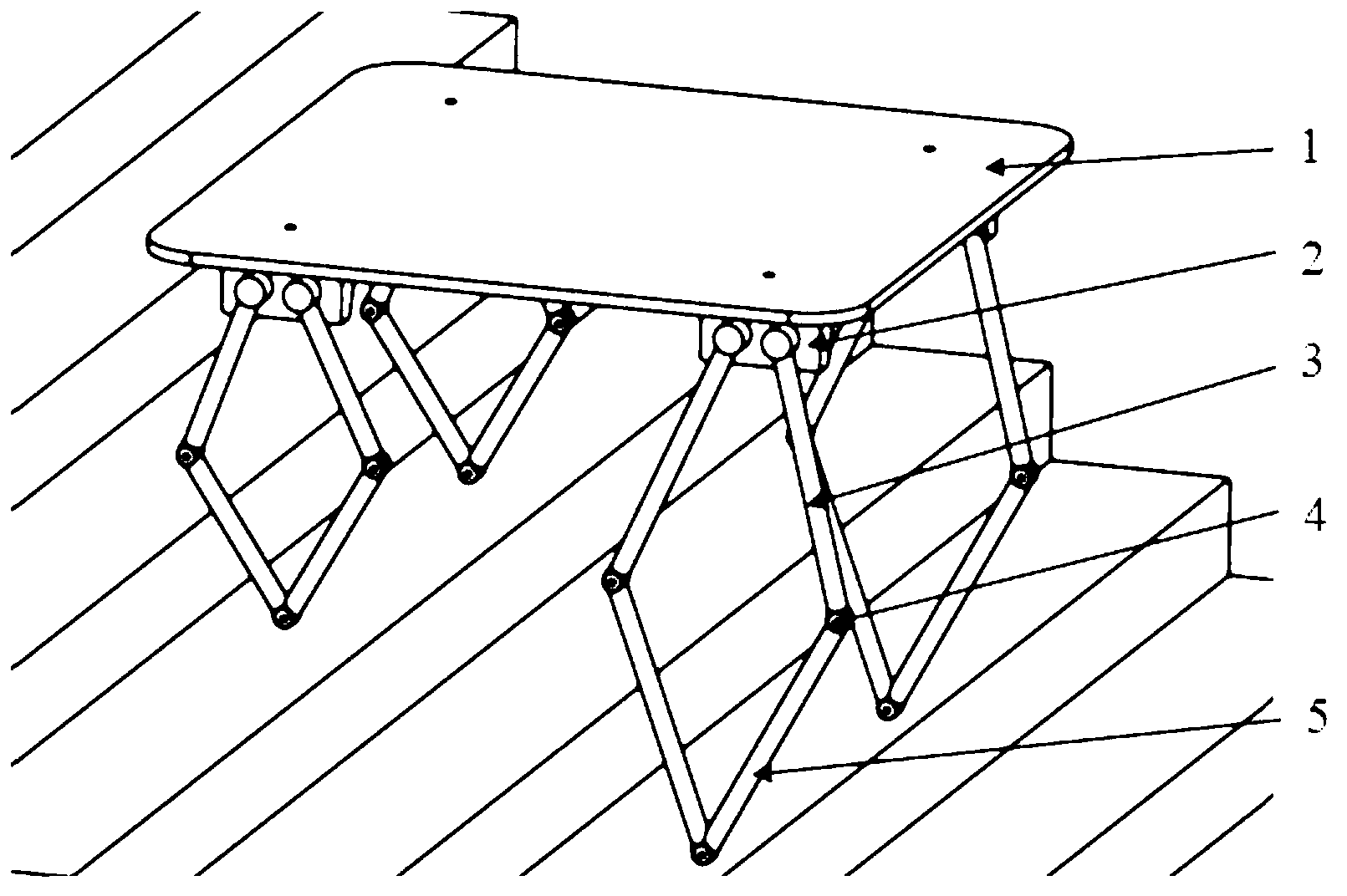

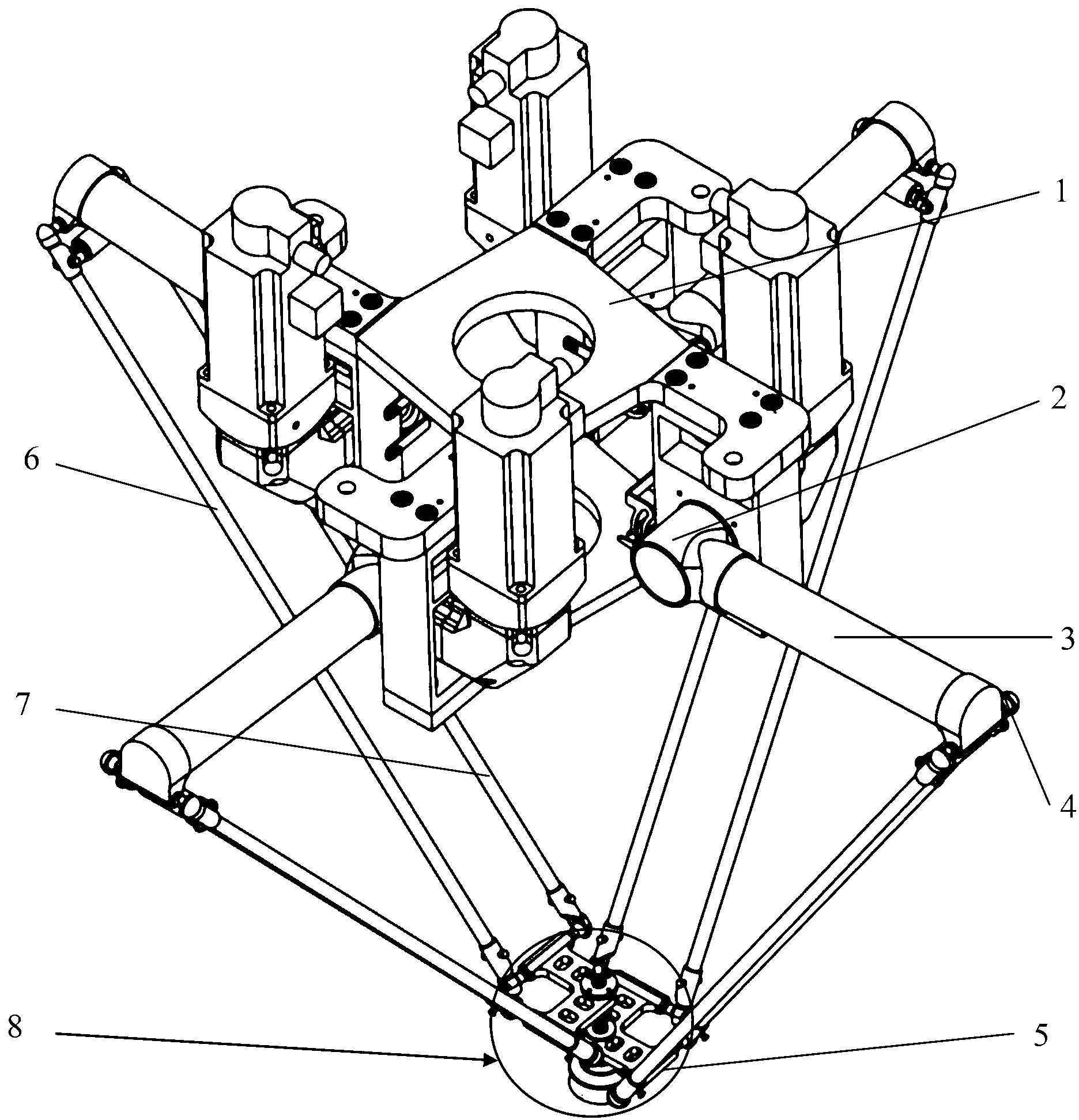

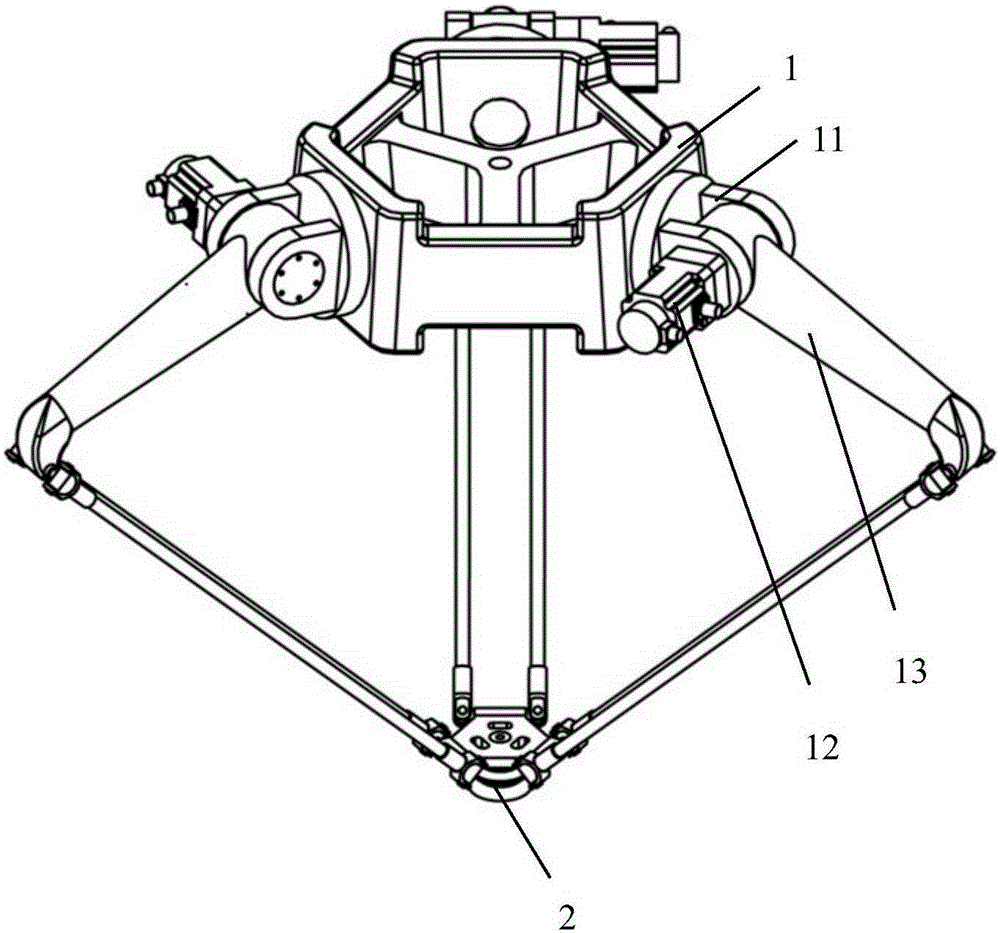

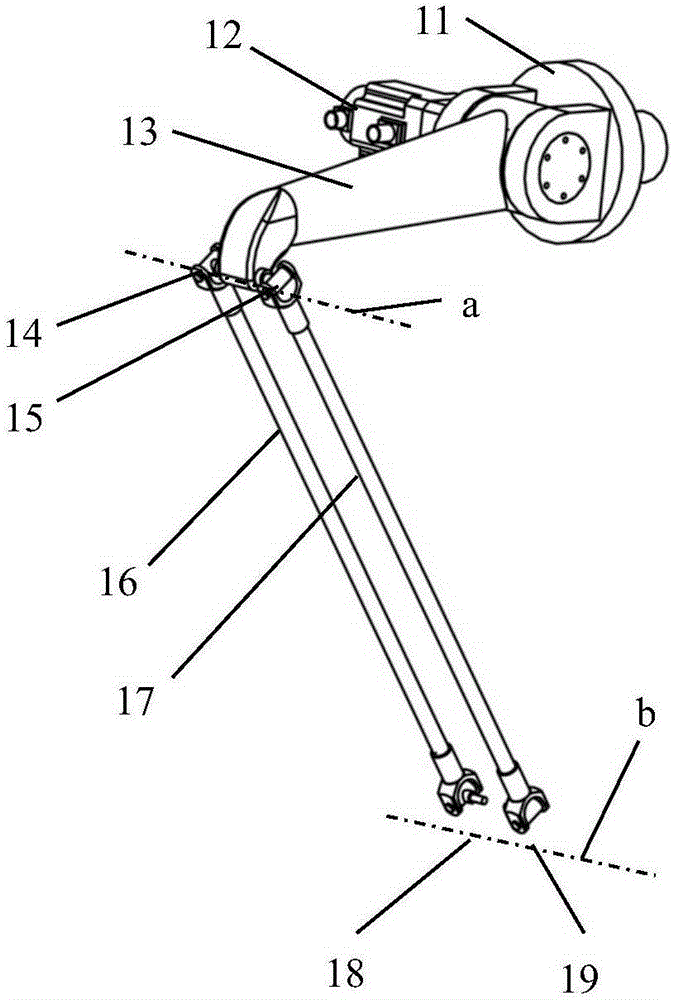

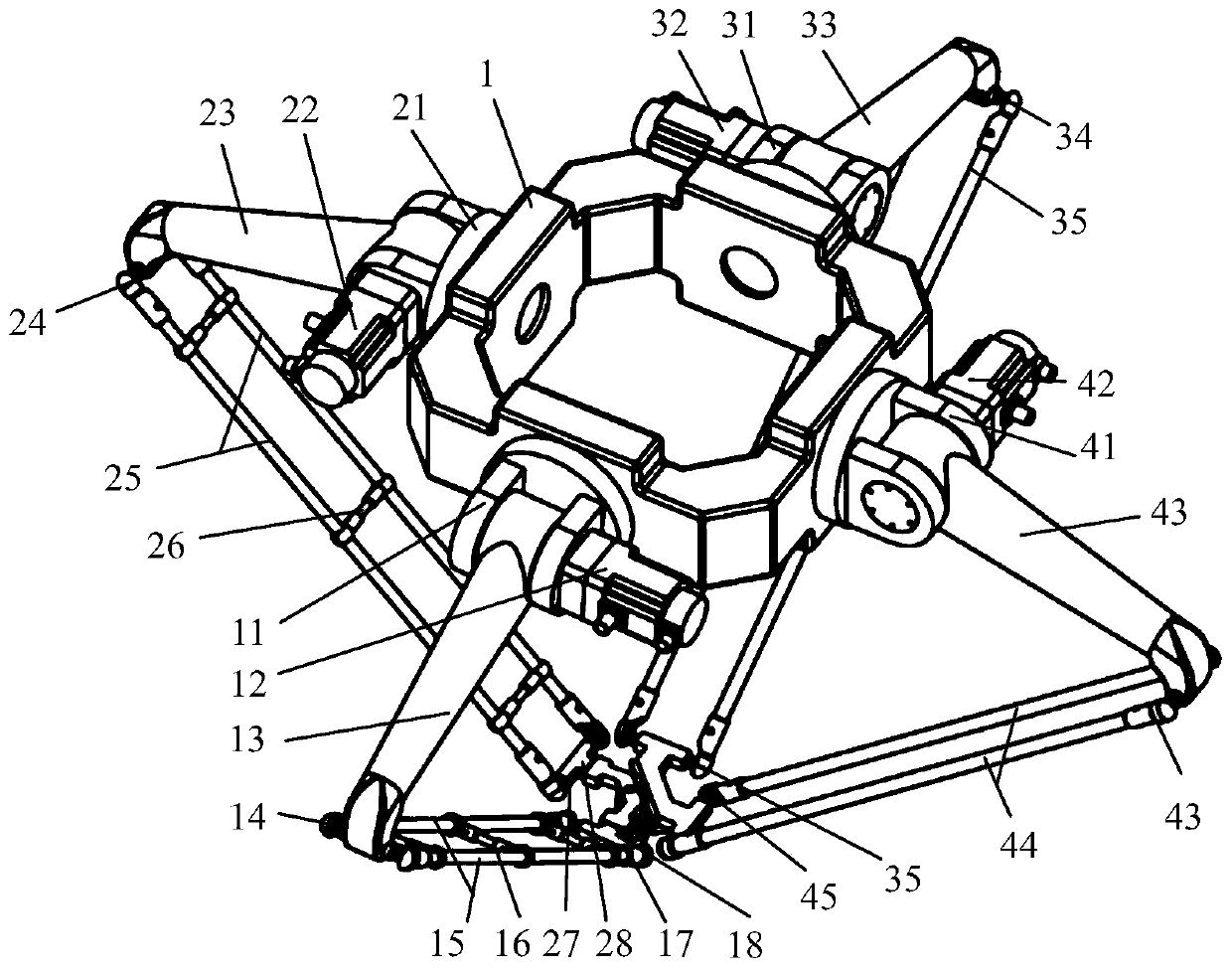

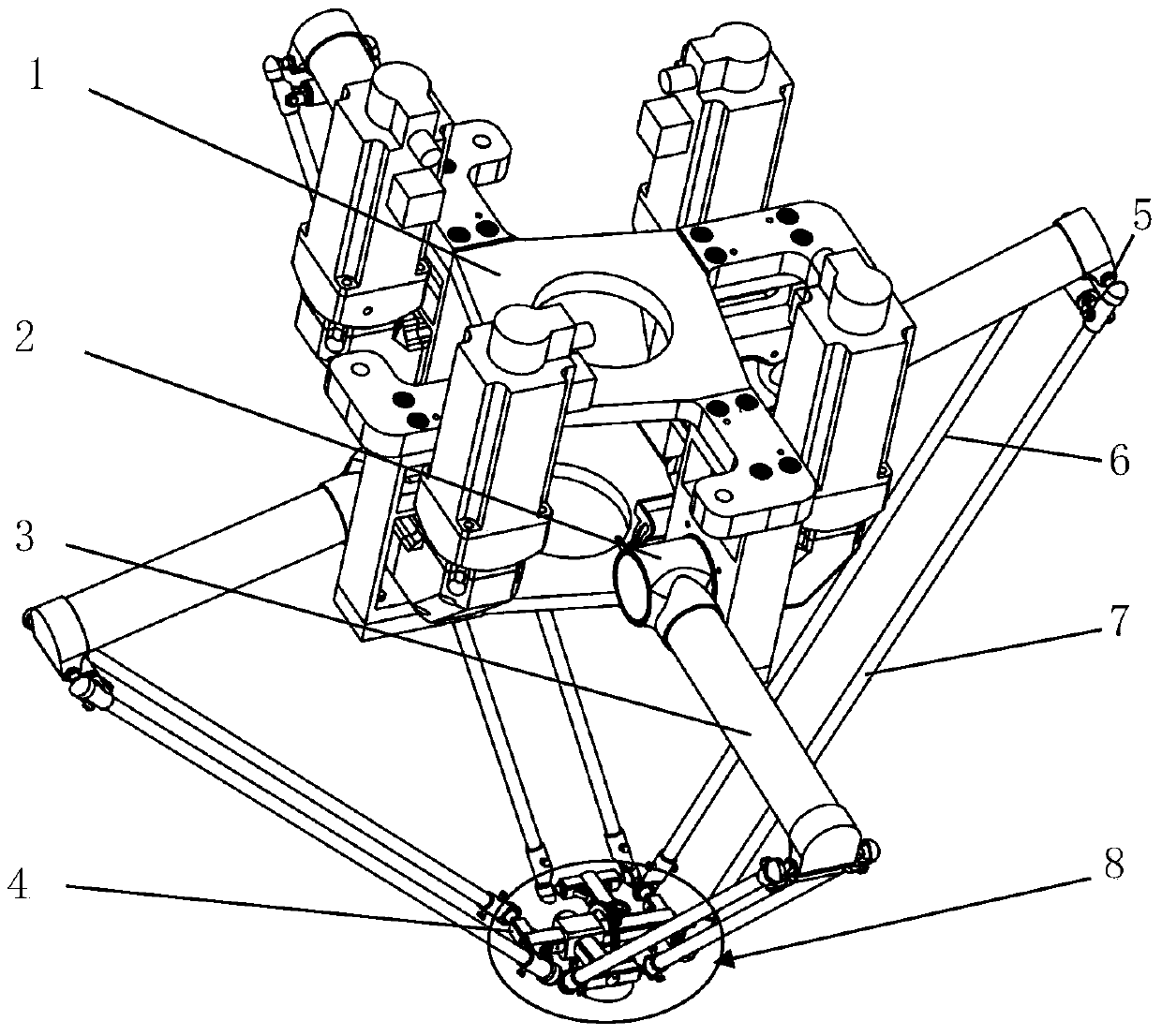

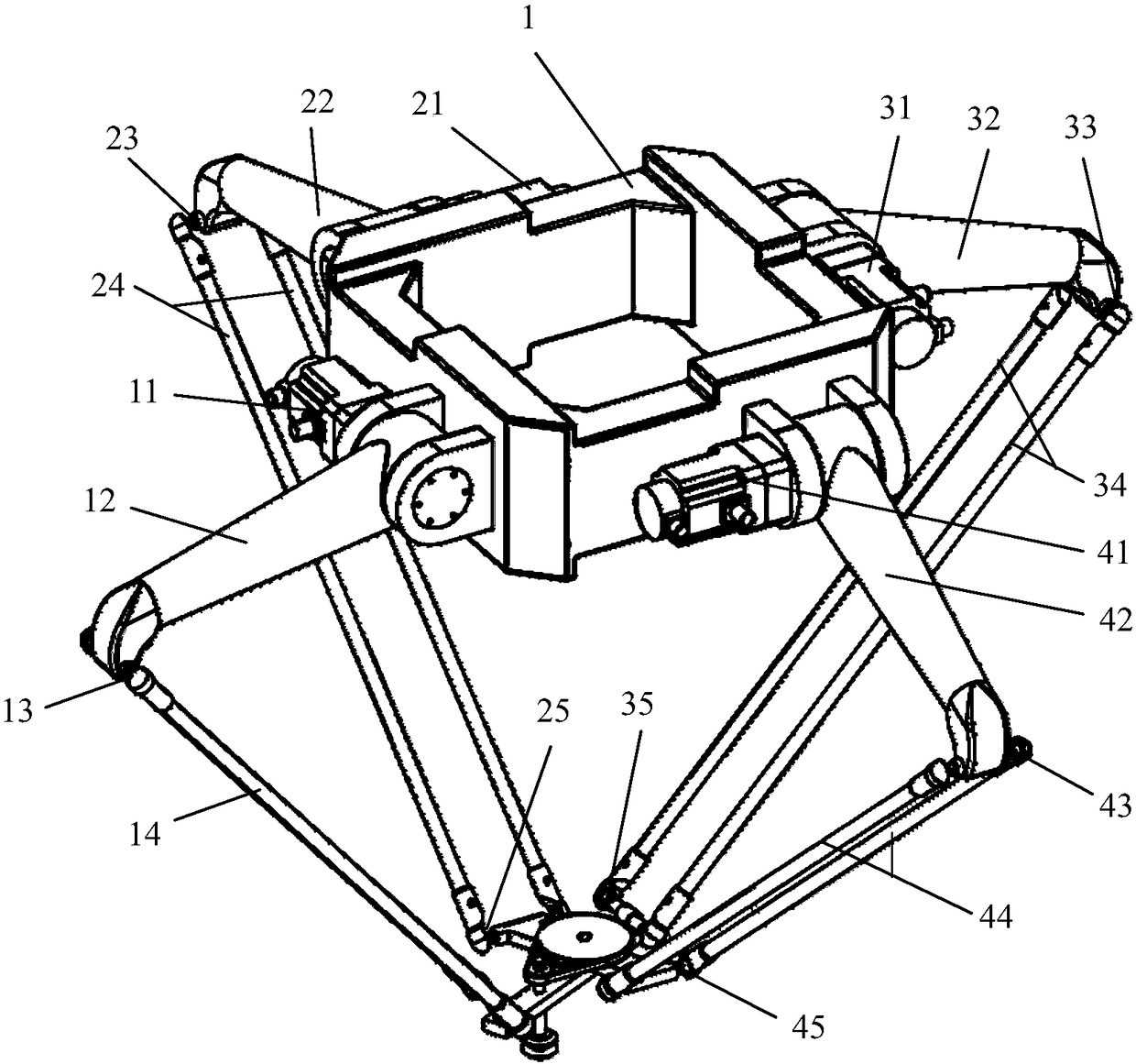

Quadruped-imitating stair-climbing robot

InactiveCN103273984AIncrease stiffnessIncrease movement speedVehiclesLeg mechanismMechanical engineering

The invention discloses a quadruped-imitating stair-climbing robot which comprises a loading plate and four parallel connection leg mechanisms connected with the loading plate and having the same structure. Two leg mechanisms parallel in a right-and-left mode are located below the front of the loading plate, and other two leg mechanisms parallel in a right-and-left mode are located below the back of the loading plate. Every leg mechanism comprises a machine frame and two coplanar branched chains. The machine frames are hinged to the loading plate, every branched chain comprises a driving rod and a driven rod, one end of every driving rod is connected with a rotating driving device, the other end of the driving rod is hinged to one end of the driven rod, and the rotating driving devices are installed on the machine frames. The other ends of two driven rods in the leg mechanisms are hinged to each other, and the machine frames and the branched chains form a planar five-rod mechanism. Legs of the quadruped-imitating stair-climbing robot are of a parallel connection structure, so that the leg mechanisms have greater rigidity in space, and higher movement speed and acceleration of the leg mechanisms can be achieved.

Owner:CHENXING (TIANJIN) AUTOMATION EQUIP CO LTD

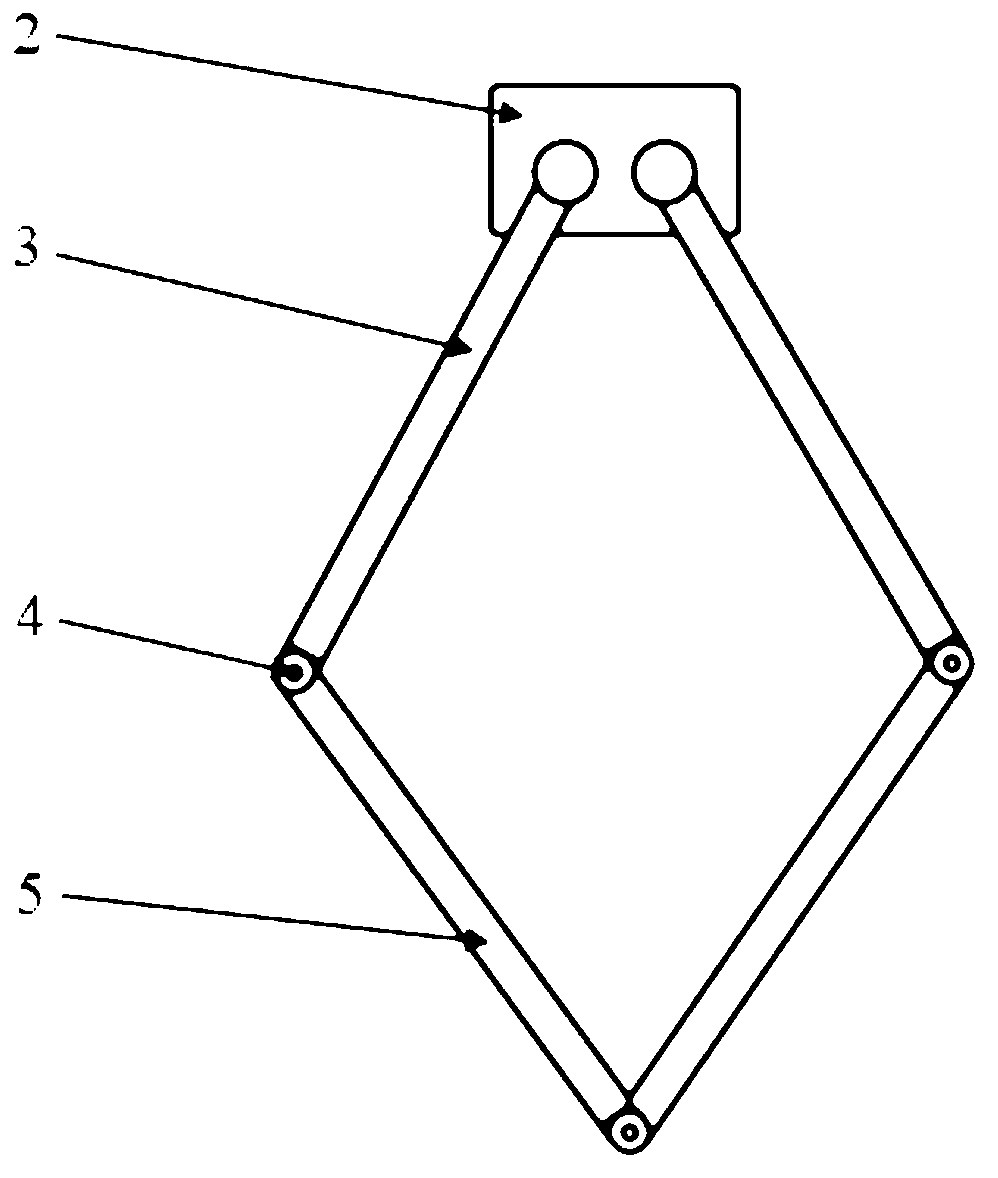

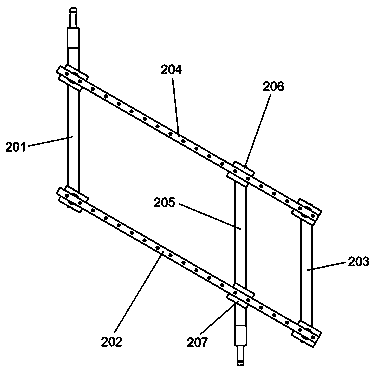

Parallel mechanism with two-degree-of-free translation function

ActiveCN103273481ALow machining accuracy requirementsHigh positioning accuracyProgramme-controlled manipulatorEngineeringMechanical engineering

The invention discloses a parallel mechanism with a two-degree-of-free translation function. The parallel mechanism comprises a fixed frame, a movable platform, two driving branched chains identical in structure and a driven branched chain, the two driving branched chains are symmetrically arranged between the fixed frame and the movable platform and on two sides of the driven branched chain, the driven branched chain comprises two rod members in left-right parallelism, the upper ends of the rod members are connected with the fixed frame through a rotating pair while the lower ends of the same are connected with the end portion of a horizontal connecting rod, the fixed frame, the two rod members and the horizontal connecting rod form a parallelogram structure, a vertical connecting rod perpendicular to the horizontal connecting rod is fixedly connected below the middle portion of the horizontal connecting rod, and the movable platform comprises a transverse rod and a vertical rod which is vertically fixed above the middle portion of the transverse rod and connected with the vertical connecting rod through a moving pair. The parallel mechanism is low in manufacturing cost, smoother in operating and higher in motion transmitting efficiency.

Owner:江苏小野智能装备有限公司

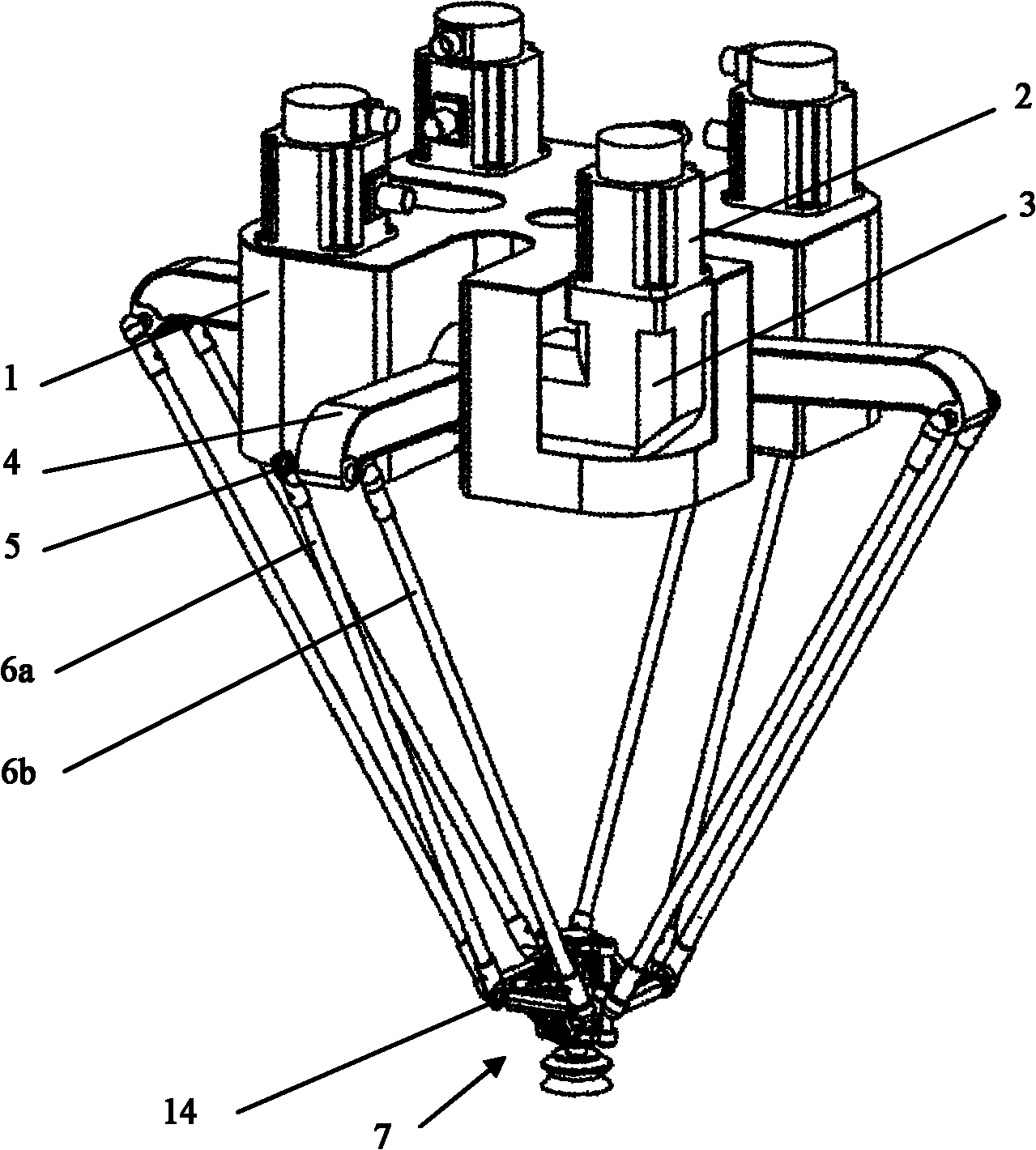

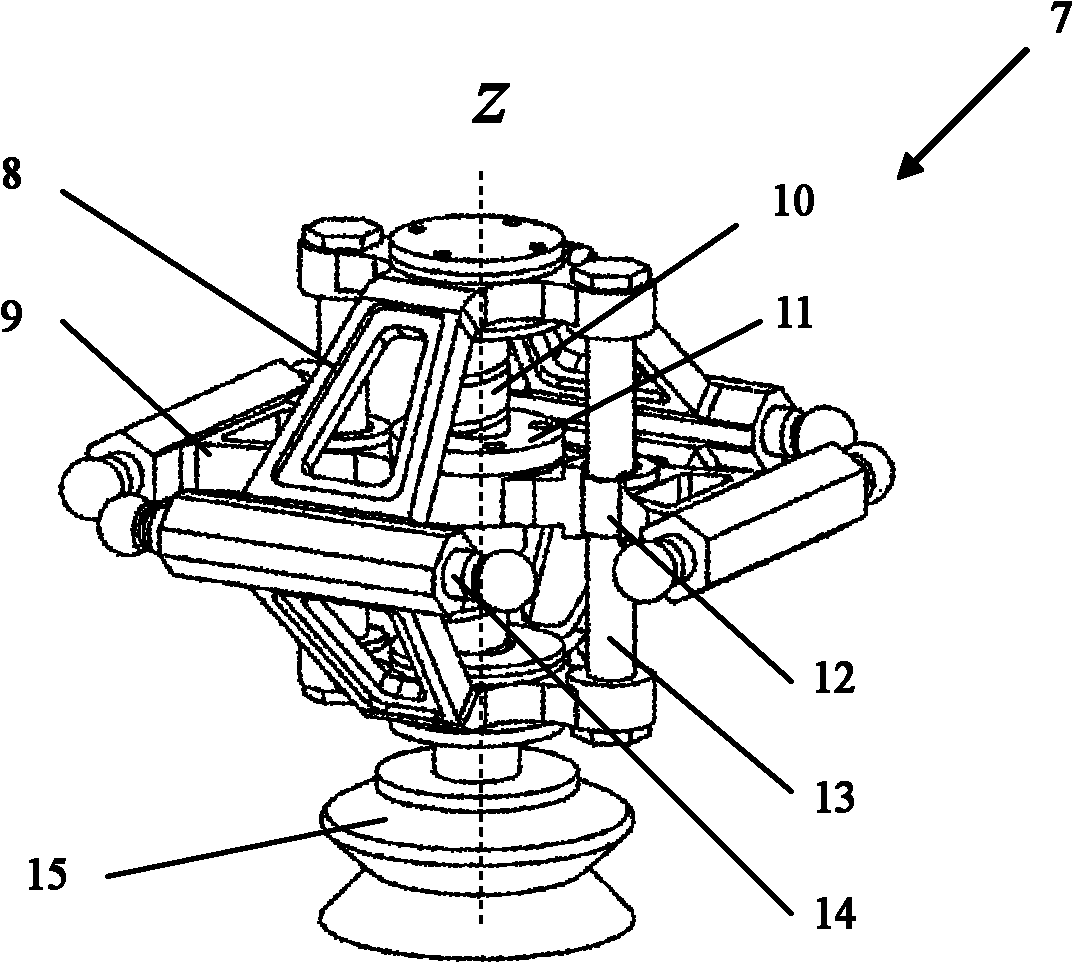

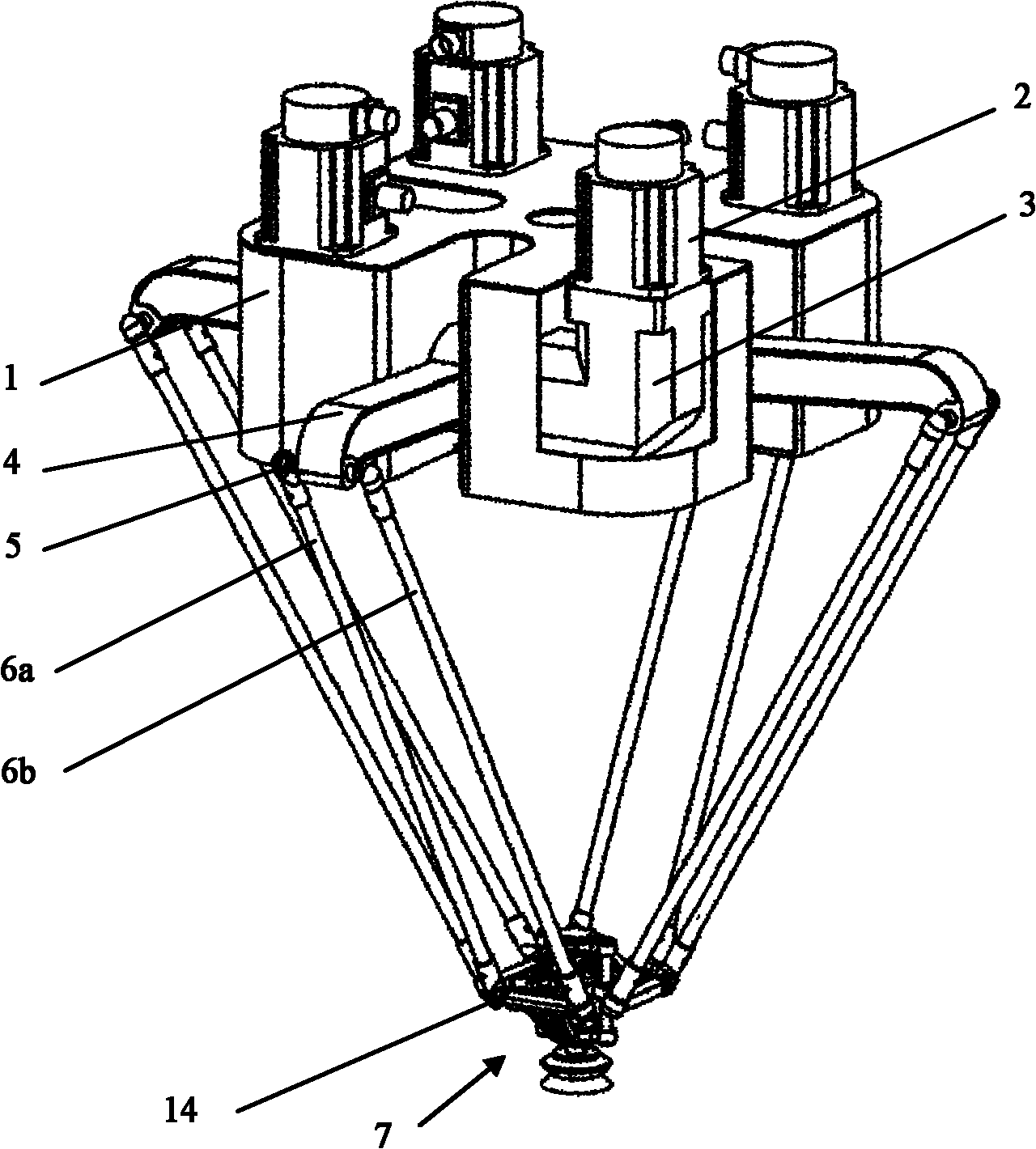

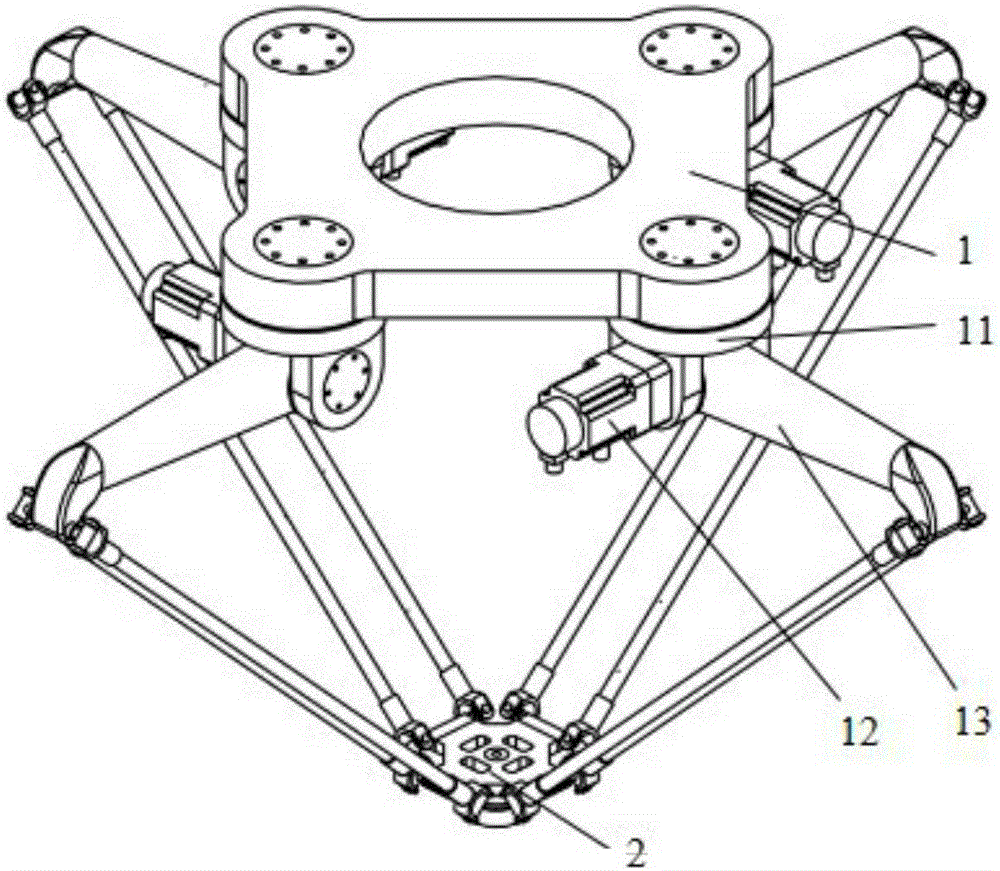

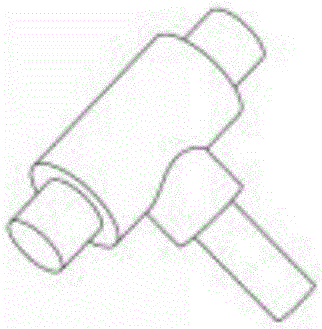

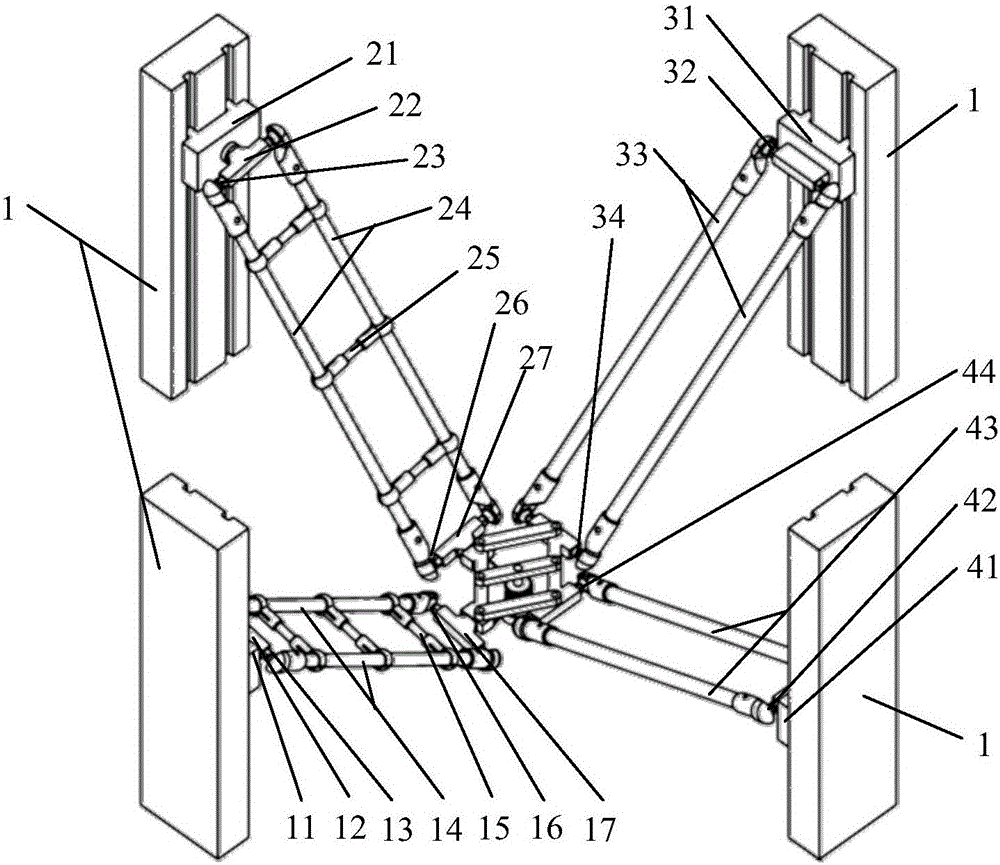

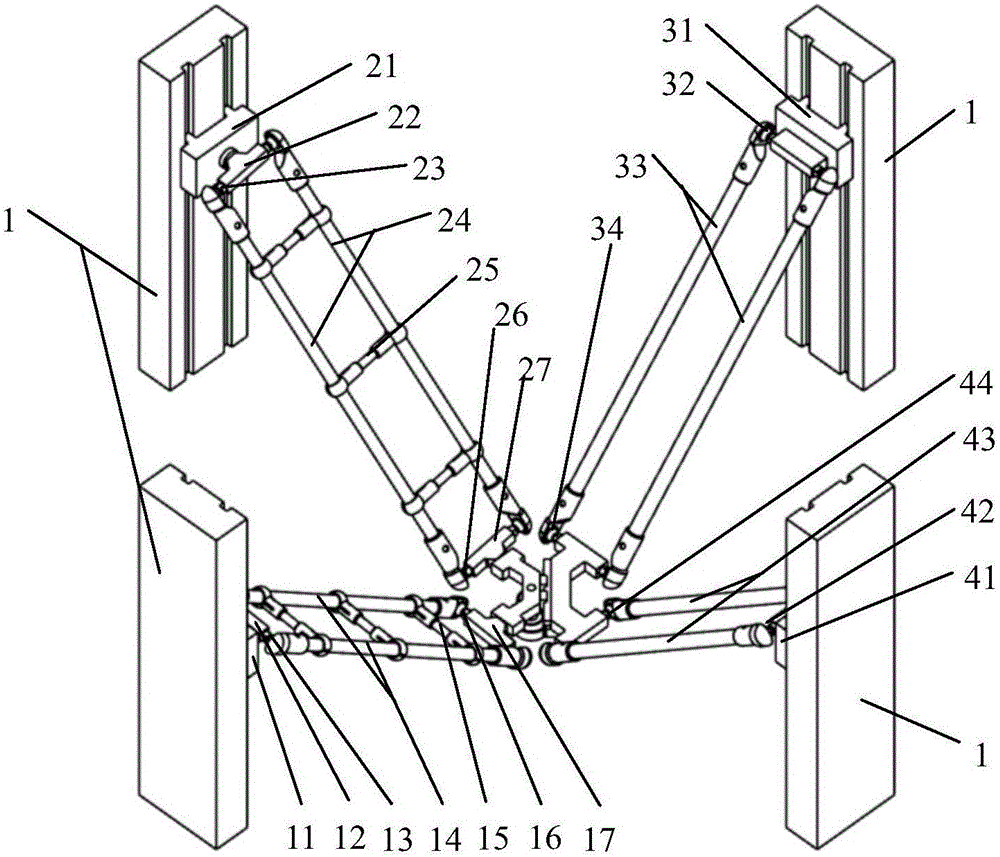

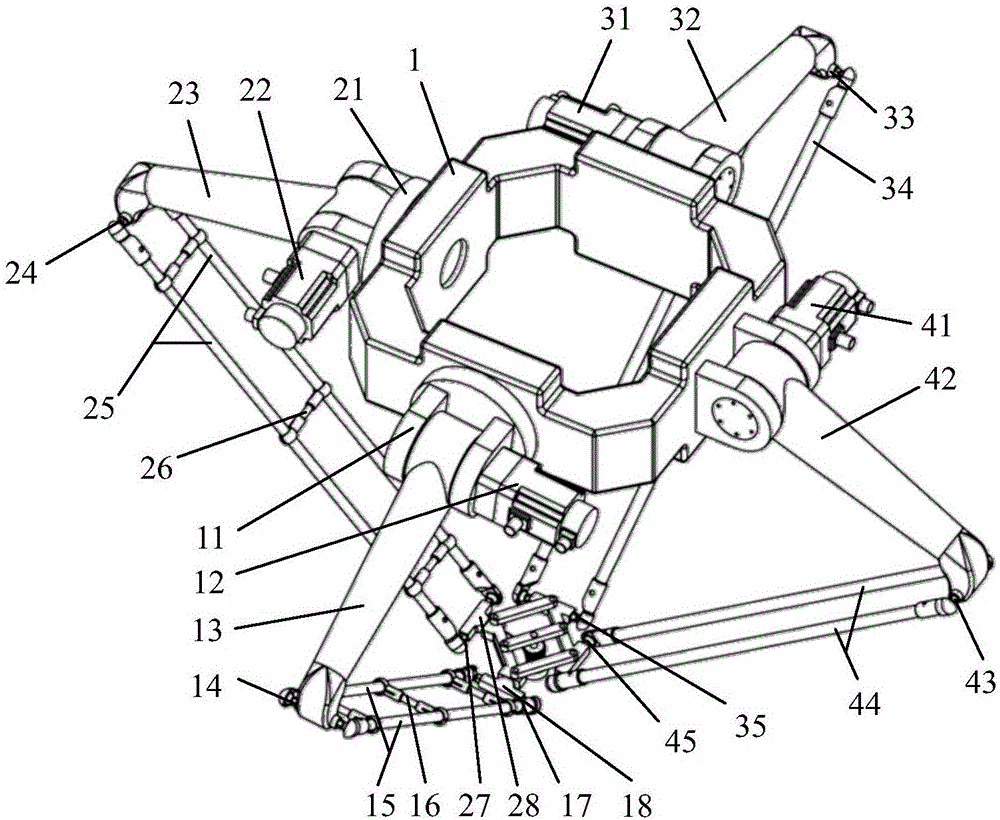

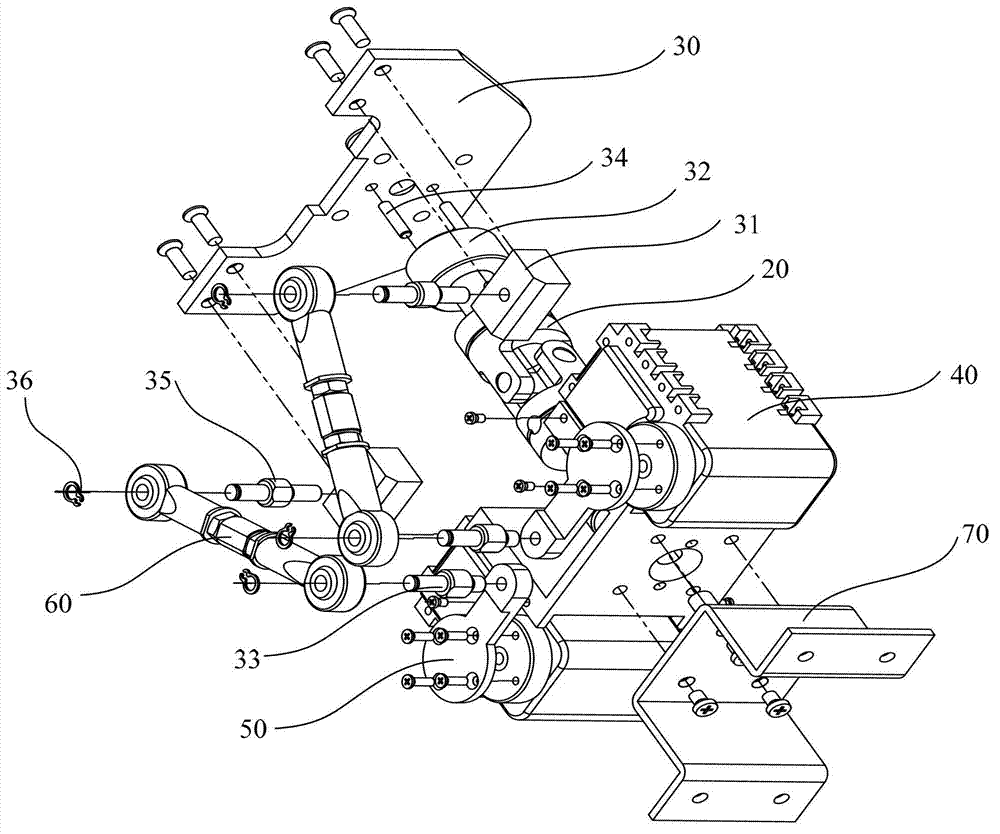

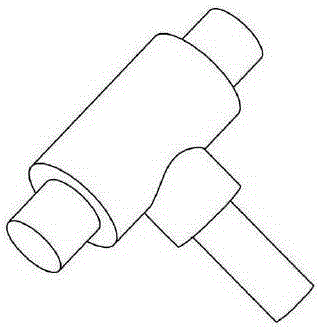

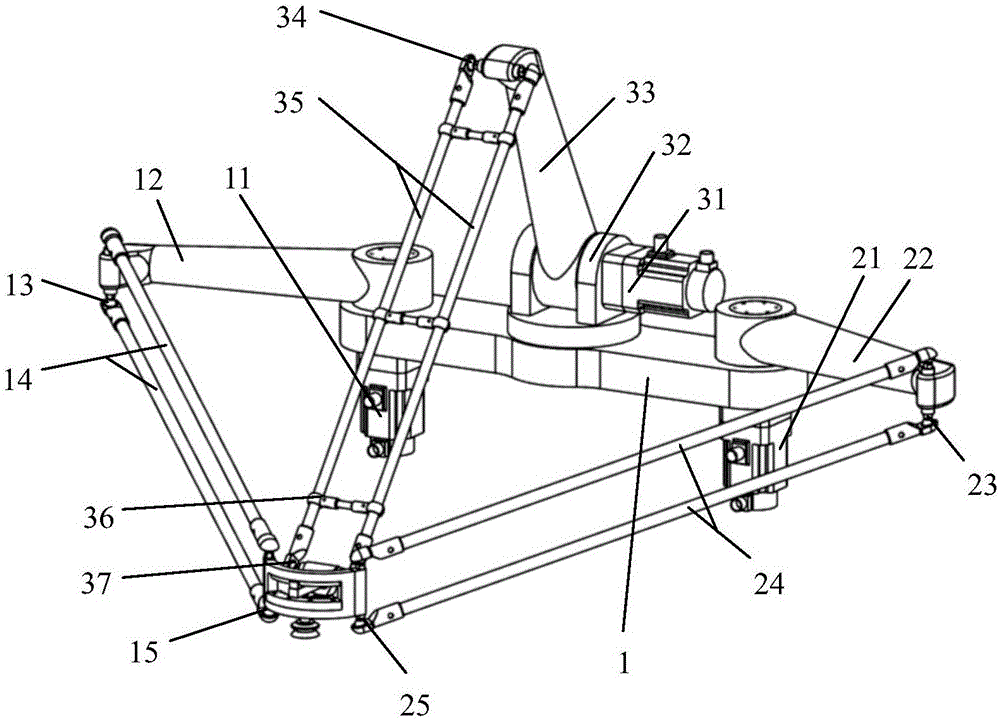

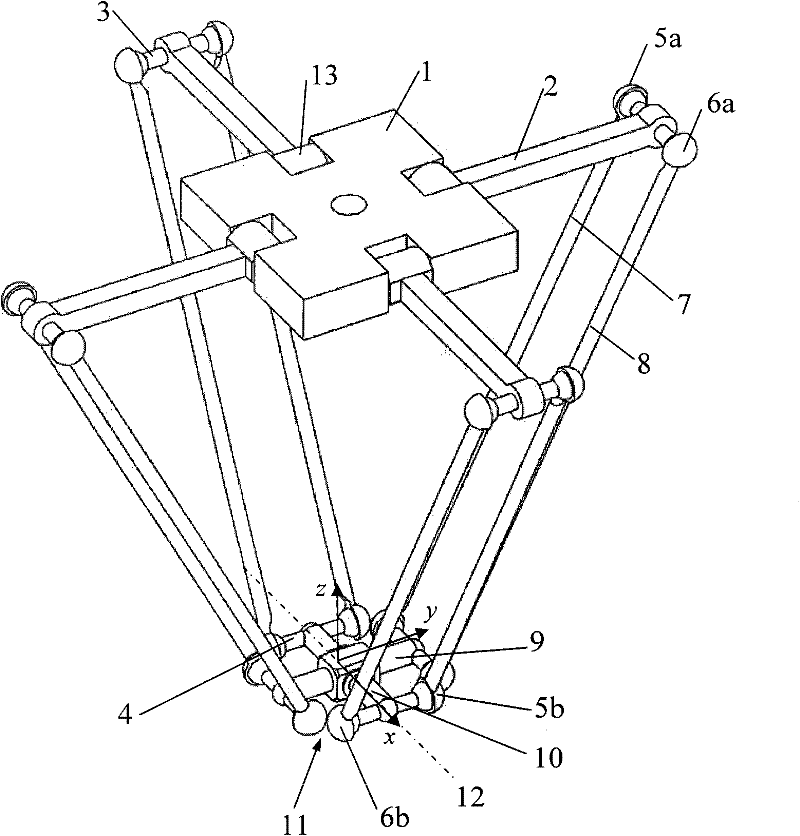

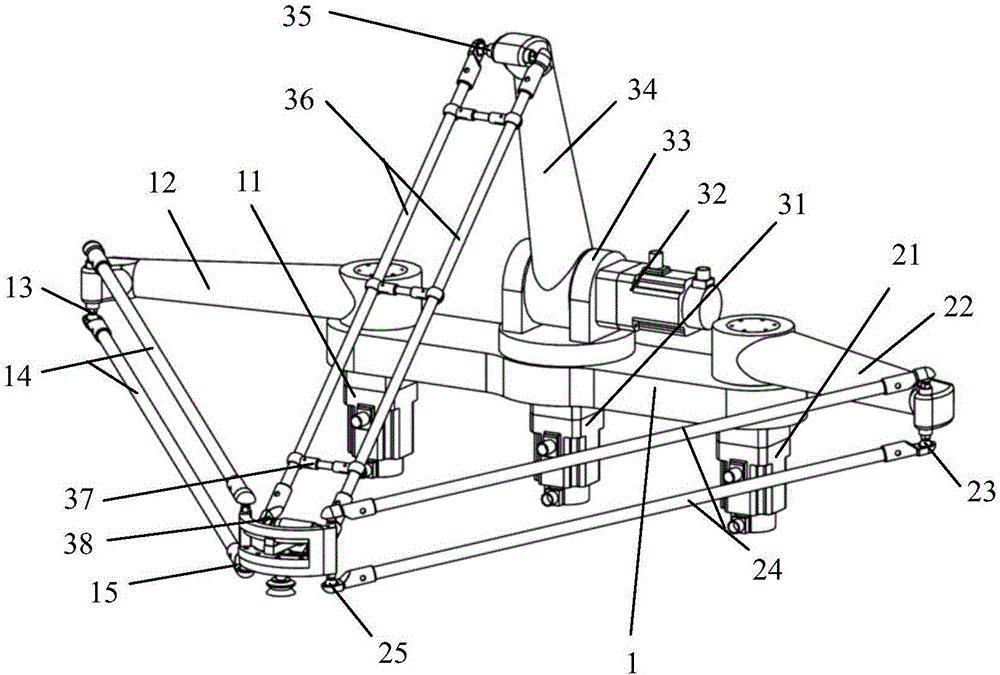

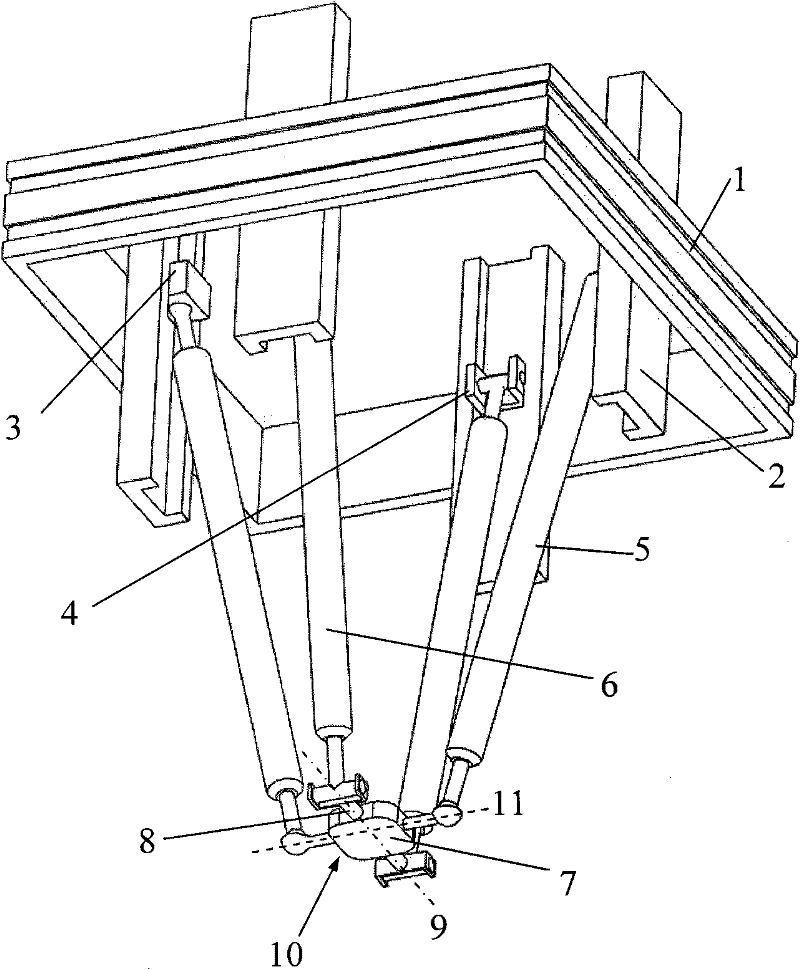

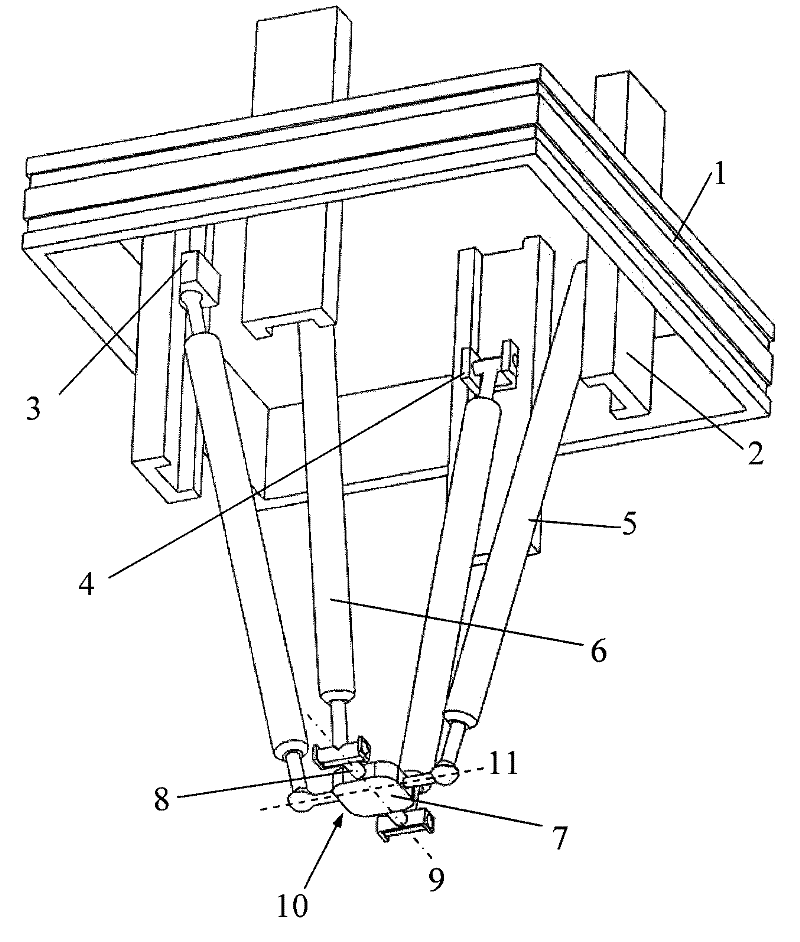

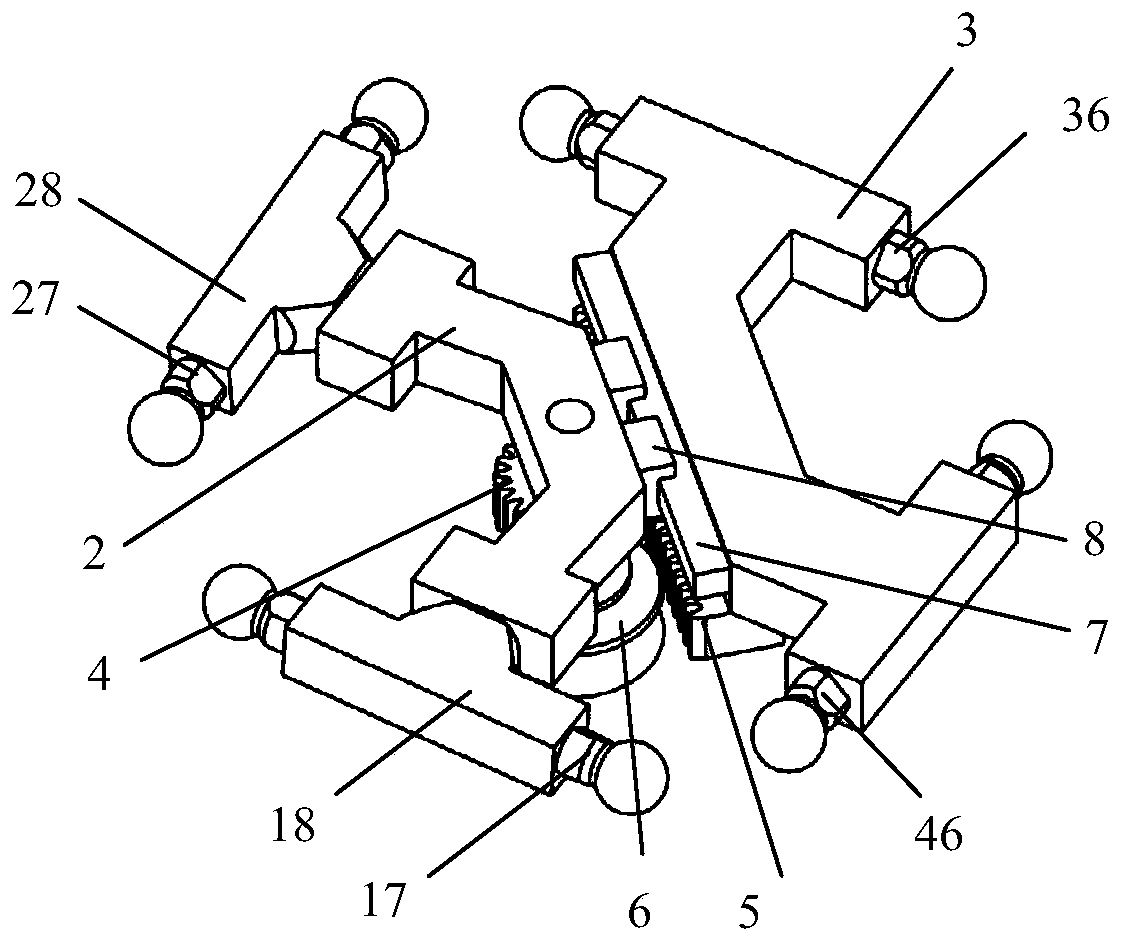

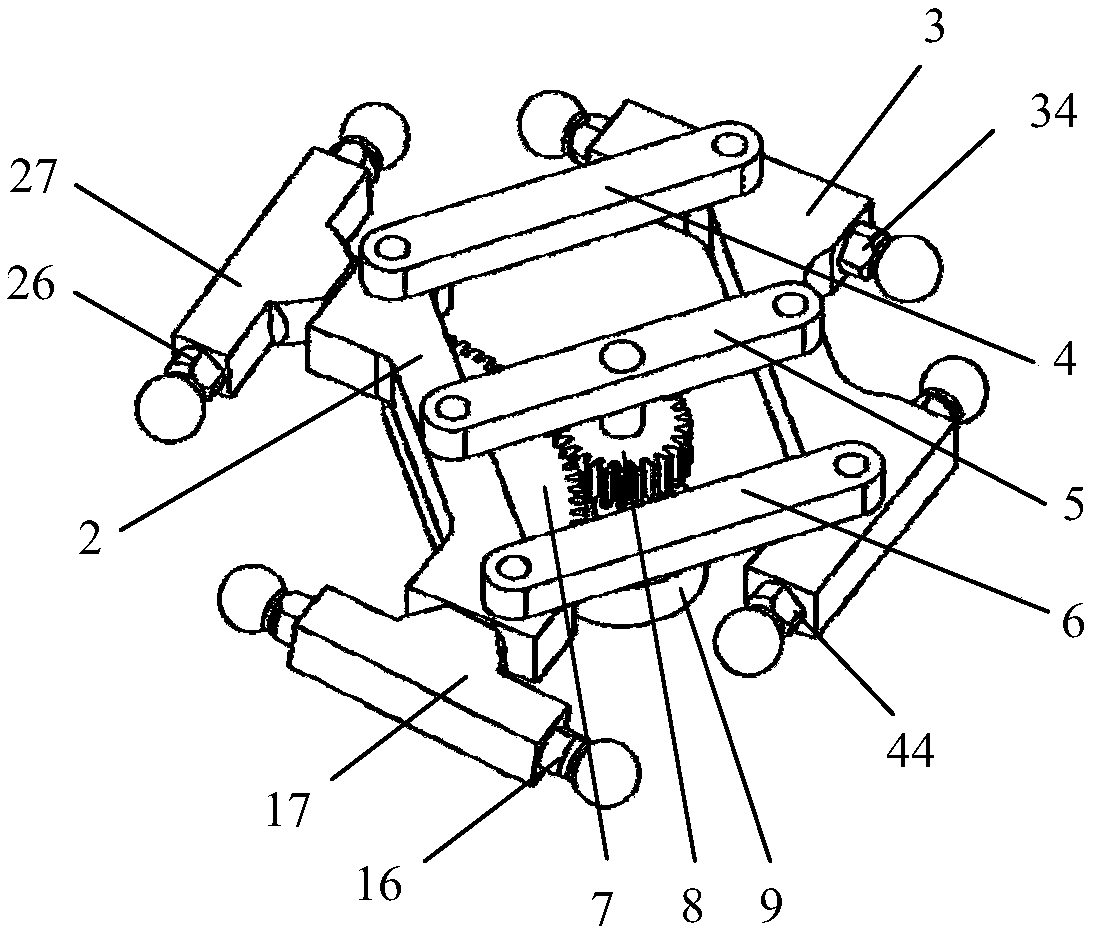

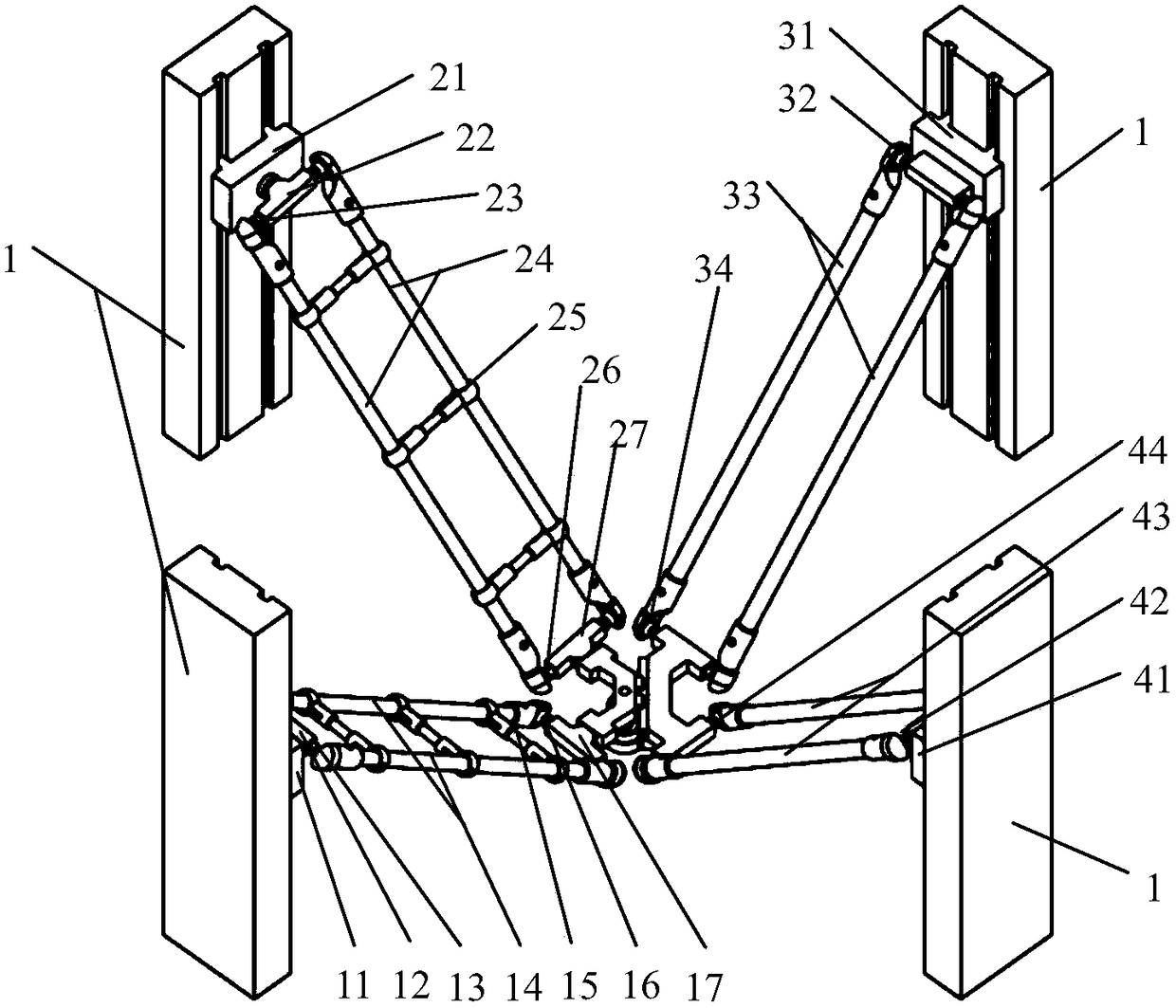

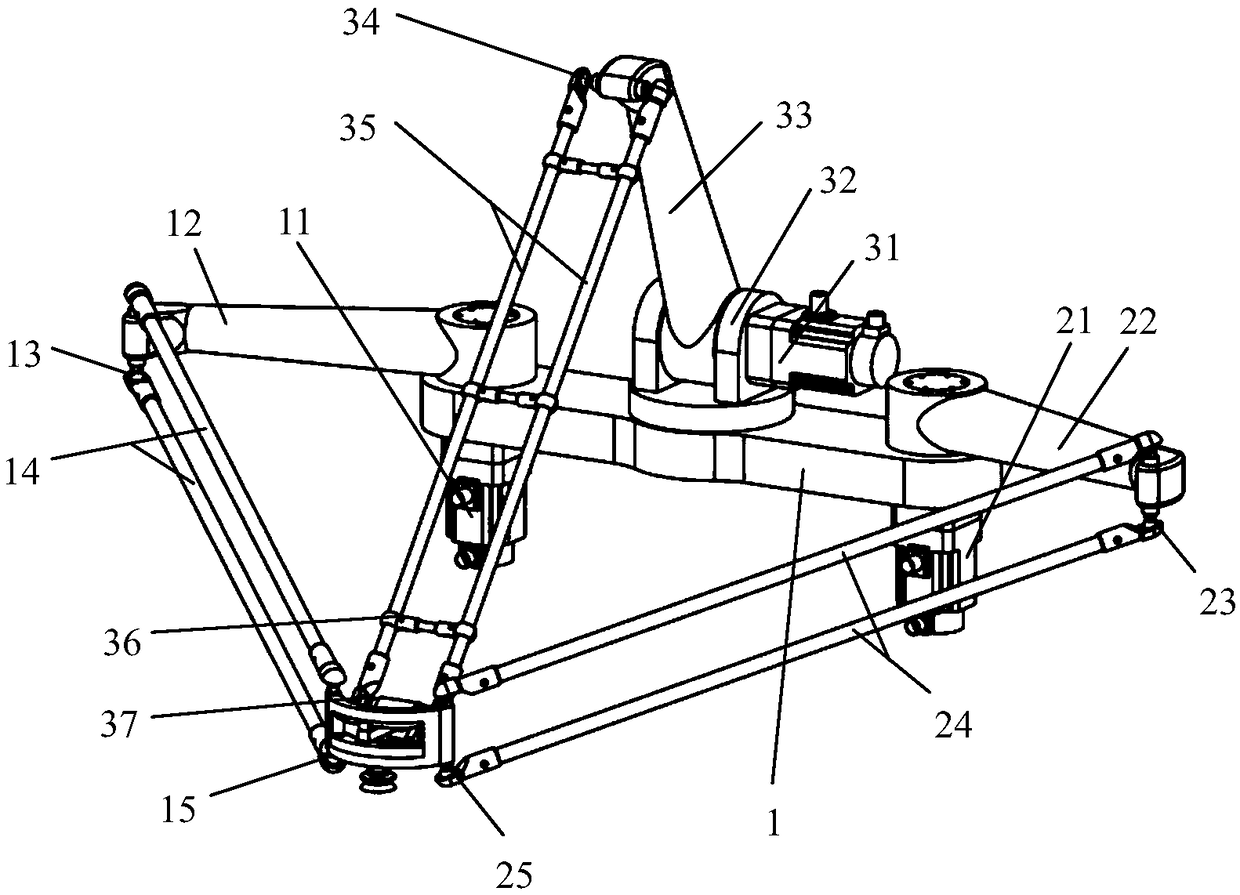

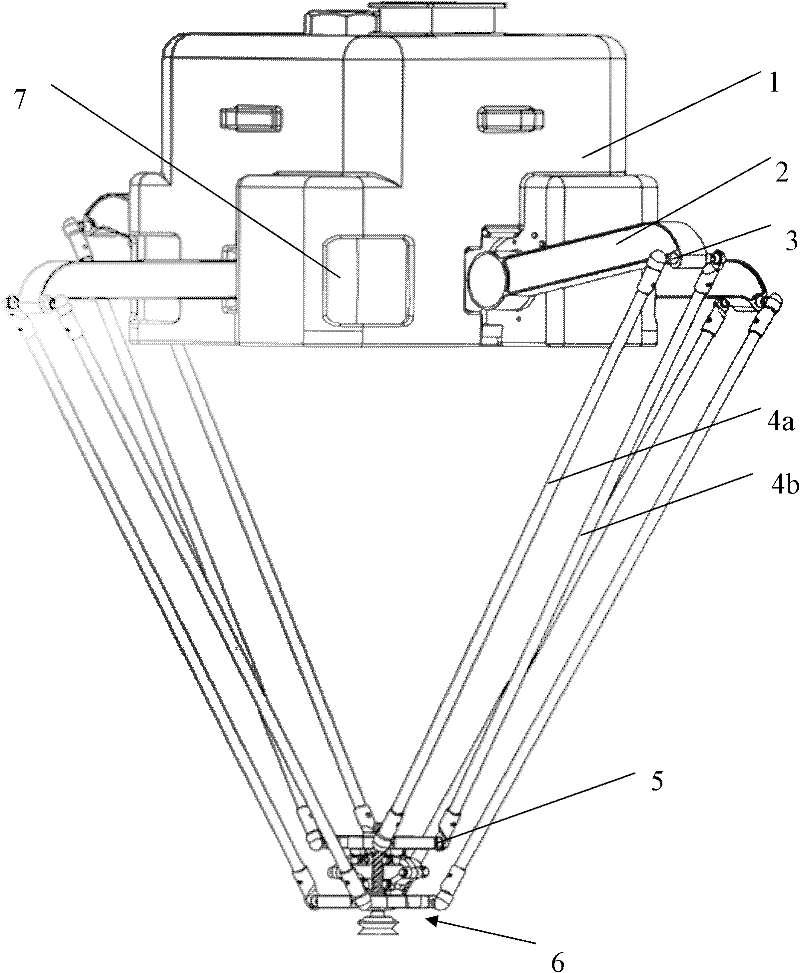

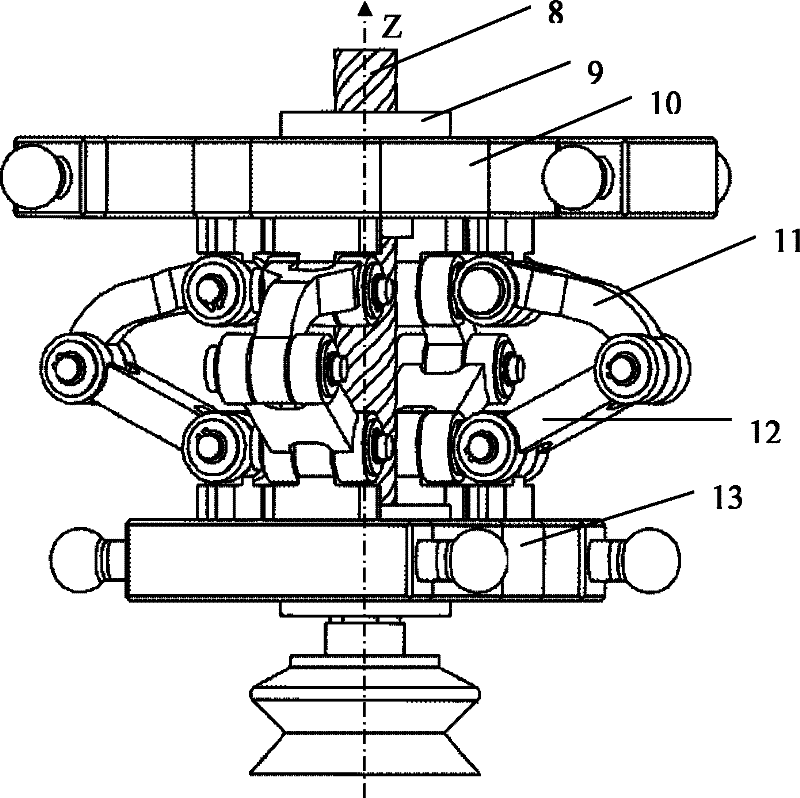

Four-degree-of-freedom parallel mechanism capable of realizing three-dimensional translation and one-dimensional rotation

ActiveCN105234929ACompact structureThe movement method is clearProgramme-controlled manipulatorFixed frameHigh acceleration

The invention discloses a four-degree-of-freedom parallel mechanism capable of realizing three-dimensional translation and one-dimensional rotation. The parallel mechanism comprises a fixed frame, a movable platform, and four branch chains which are arranged between the fixed frame and the movable platform and adopt the same structure, wherein each branch chain comprises a rotating fork, an active arm, two parallel slave arms which are equal in lengths, and four T-shaped shafts; the rotating forks are connected with the fixed frame in a rotating manner; each active arm is connected to the inside of the corresponding rotating fork in a rotating manner; one ends of every two corresponding slave arms are connected with the corresponding active arm through two T-shaped shafts, and the other ends of the slave arms are connected with the movable platform through two T-shaped shafts. The movable platform of the parallel mechanism adopts a single-platform structure, and has the characteristics of simple structure, light weight and the like, and the realization of dynamic response characteristics with high speed and high acceleration is facilitated.

Owner:NANJING UNIV OF SCI & TECH

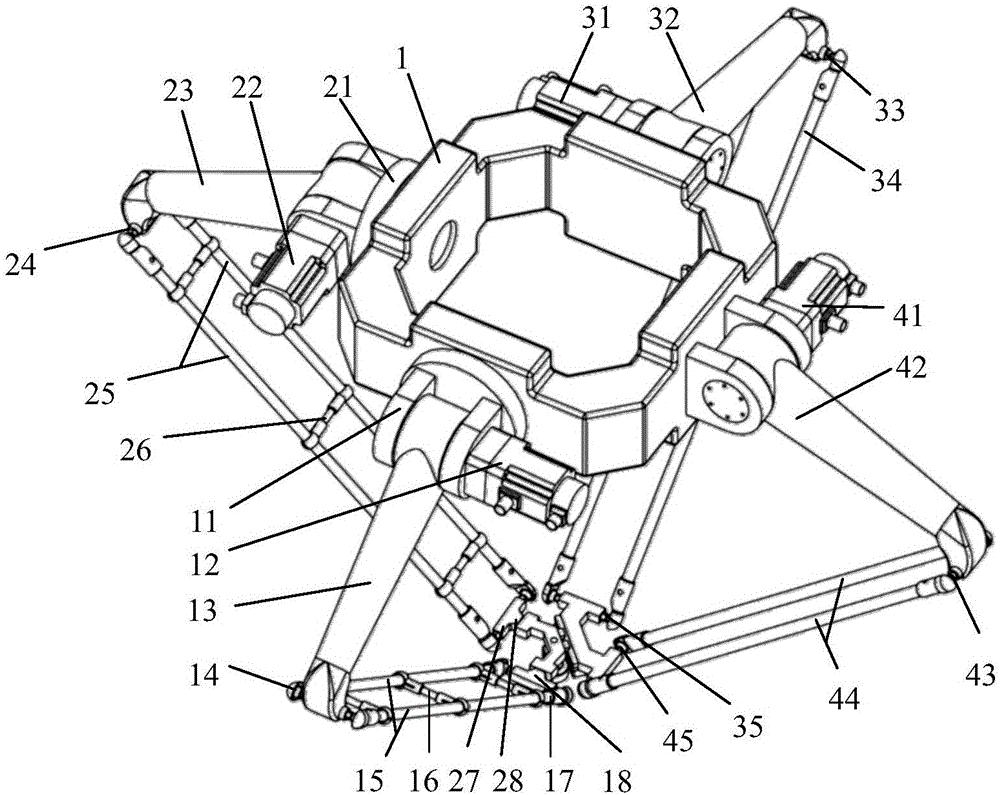

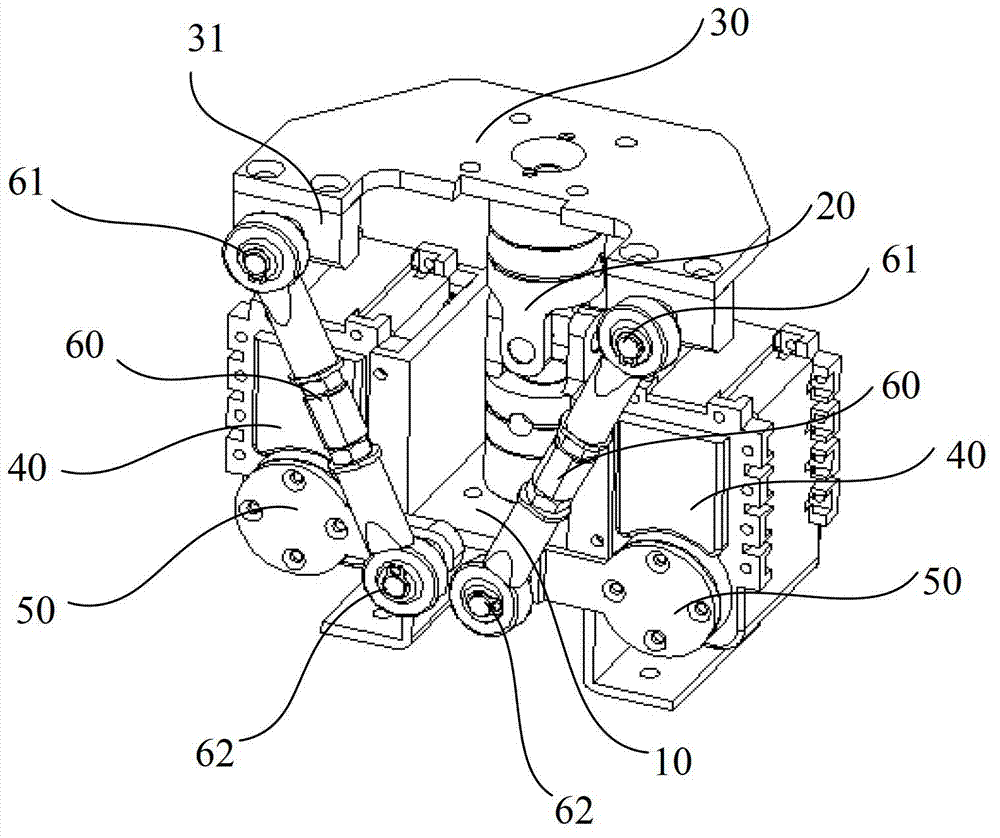

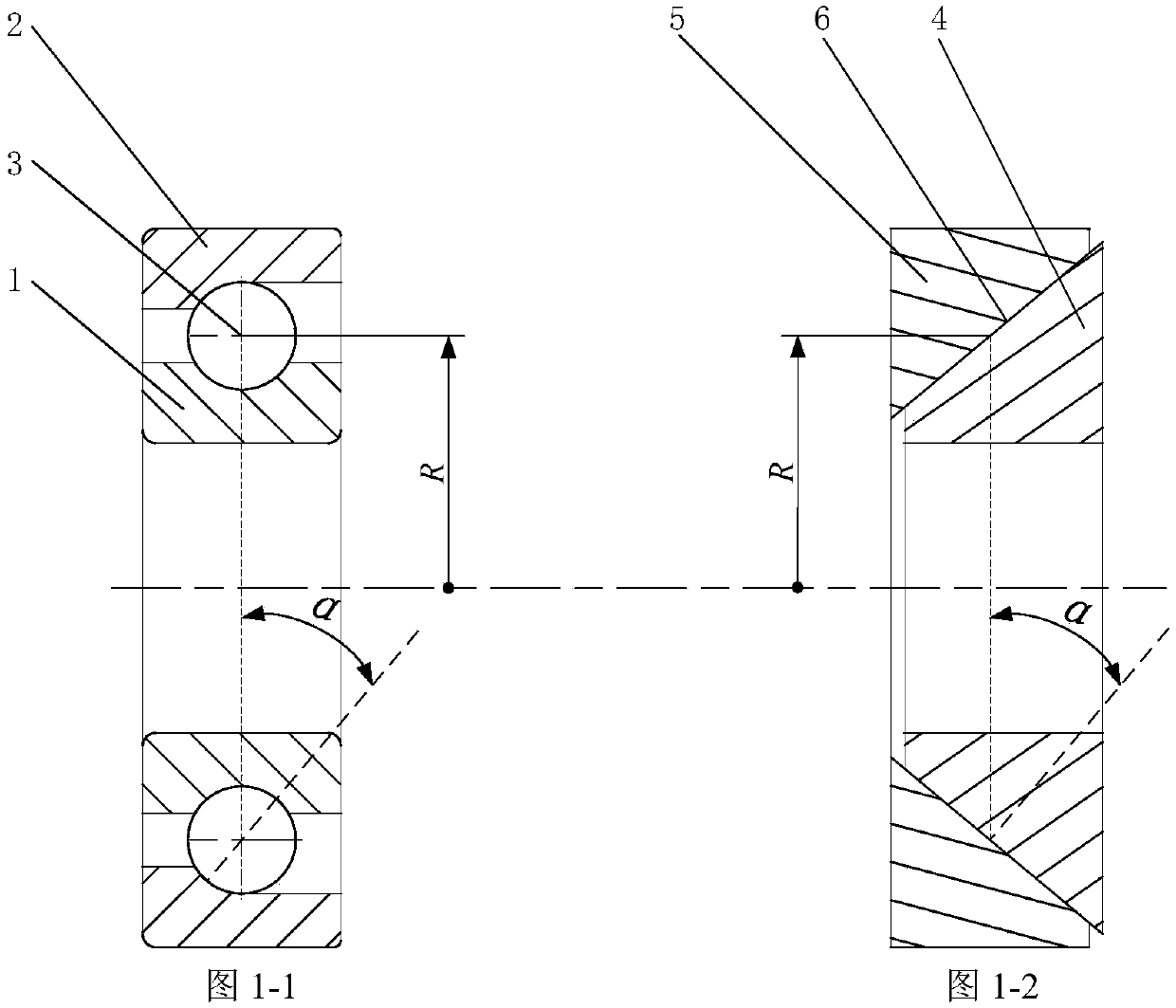

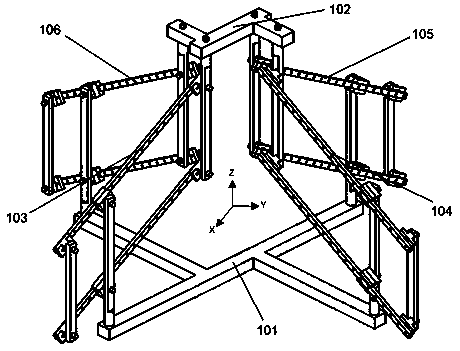

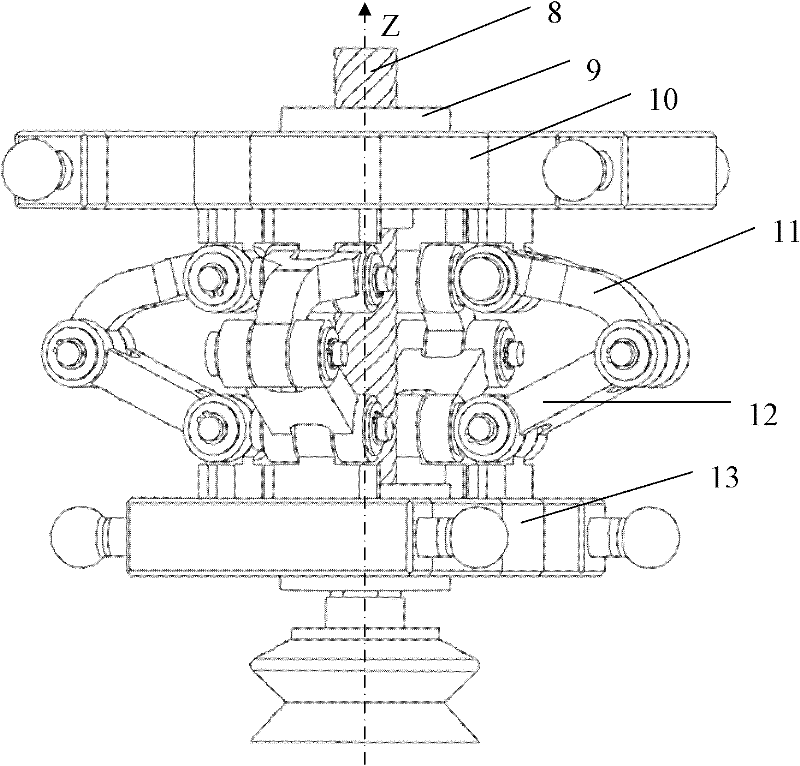

Parallel mechanism with three-dimensional translation and one-dimensional rotation functions

InactiveCN103317500ASimple structureThe movement method is clearProgramme-controlled manipulatorEngineeringMechanical engineering

The invention discloses a parallel mechanism with three-dimensional translation and one-dimensional rotation functions. The parallel mechanism comprises a fixing frame, a moving platform and four branched chains with the same structure, wherein the branched chains are symmetrically arranged between the fixing frame and the moving platform. The moving platform comprises an upper platform and a lower platform which are parallel to each other and spatially symmetric, the upper platform and the lower platform are respectively fixedly connected with two adjacent lower connecting shafts and are connected through a reversing mechanism, and the reversing mechanism can transform relative movement of the upper platform and the lower platform into rotation around the rotation center line of the reversing mechanism. The parallel mechanism is simple in structure and clear in movement mode and has higher rigidity in space owing to symmetric structural distribution, an amplifying mechanism is omitted, the weight and complexity of the moving platform are greatly reduced, the parallel mechanism can realize higher movement speed and accelerated speed, and accordingly, mechanism efficiency is improved. The parallel mechanism can be widely applied to the field of sorting, packaging and the like.

Owner:CHENXING (TIANJIN) AUTOMATION EQUIP CO LTD

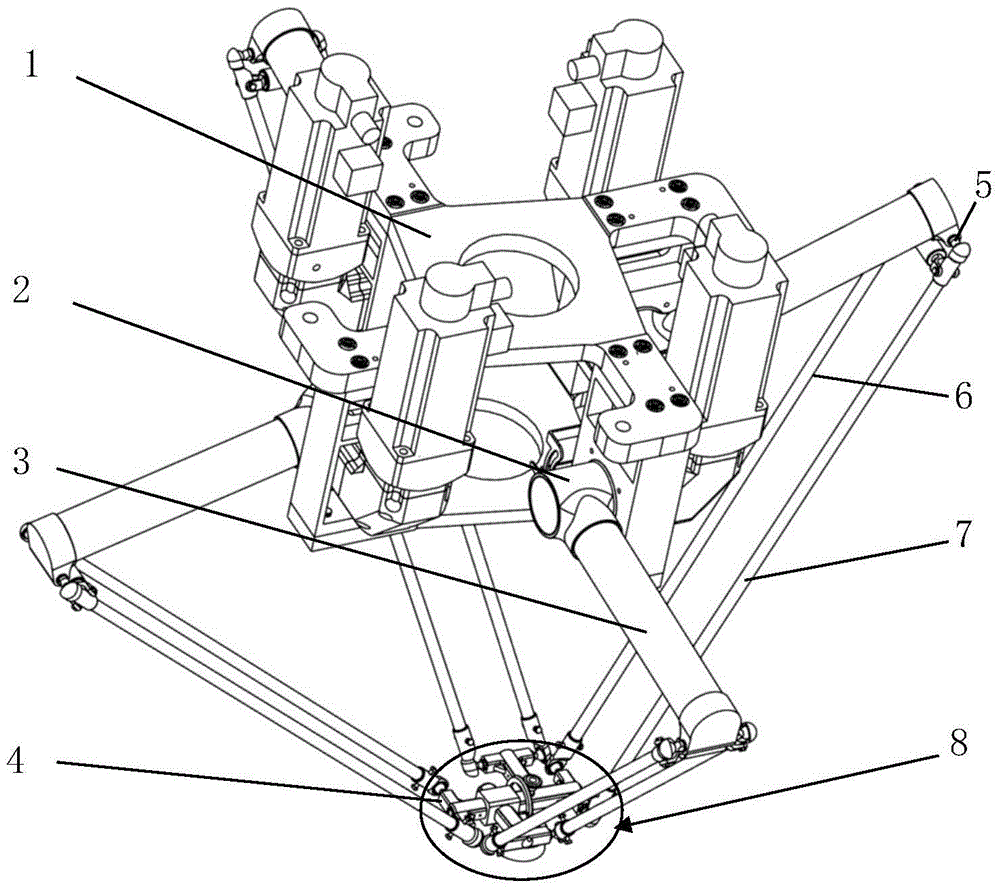

Three-degree-of-freedom high-speed parallel robot mechanism

InactiveCN109048867AThe structure is compactThe movement method is clearProgramme-controlled manipulatorFixed frameEngineering

The invention discloses a three-degree-of-freedom high-speed parallel robot mechanism. The mechanism comprises a fixing frame, a supporting platform, a moving platform as well as a first branch chain,a second branch chain and a third branch chain which are arranged between the fixing frame and the moving platform; each of the three branch chains comprises a near frame rod, far frame rods and a rotating fork; the rotating forks of the three branch chains are rotationally or fixedly connected to the supporting platform; one end of each near frame rod is connected with the corresponding rotatingfork, and the other end is connected with the corresponding far frame rods; the far frame rods are connected with the moving platform; and the supporting platform is rotationally connected with the fixing frame. The mechanism is ingenious, simple and compact in structure and clear in motion mode, two-dimensional translational motion and one-dimensional rotation can be realized, the mechanism hasvery large working space, supporting rods are adopted between the far frame rods of the third branch chain, the rigidity and the dynamic response characteristic of the mechanism are favorably improved, and the high speed and the high acceleration are favorably realized.

Owner:NANJING UNIV OF SCI & TECH

High-speed parallel robot mechanism capable of realizing SCARA motion

ActiveCN106584426ACompact structureThe movement method is clearProgramme-controlled manipulatorSlide plateSpherical joint

The invention discloses a high-speed parallel robot mechanism capable of realizing SCARA motion. The high-speed parallel robot mechanism comprises fixed brackets, a mobile platform as well as a first support chain, a second support chain, a third support chain and a fourth support chain which are arranged between the mobile platform and the fixed brackets, wherein each of the first support chain and the second support chain comprises a slide plate, a rotating shaft A, two parallel far frame rods with equal length and a rotating shaft B, the slide plate is connected with the fixed brackets through a slide pair, the rotating shaft A is rotationally connected with the slide plate, one end of each far frame rod is in spherical joint with the rotating shaft A, the other end is in spherical joint with the rotating shaft B, and the rotating shaft B is rotationally connected with the mobile platform; and each of the third support chain and the fourth support chain comprises a slide plate and two parallel far frame rods with equal length, the slide plate is connected with the fixed frame through a slide pair, one end of each far frame rod is in spherical joint with the slide plate, and the other end is in spherical joint with the mobile platform. The high-speed parallel robot mechanism is skillful in design, compact in structure and can adapt to complicated gripping and releasing environments.

Owner:江苏小野智能装备有限公司

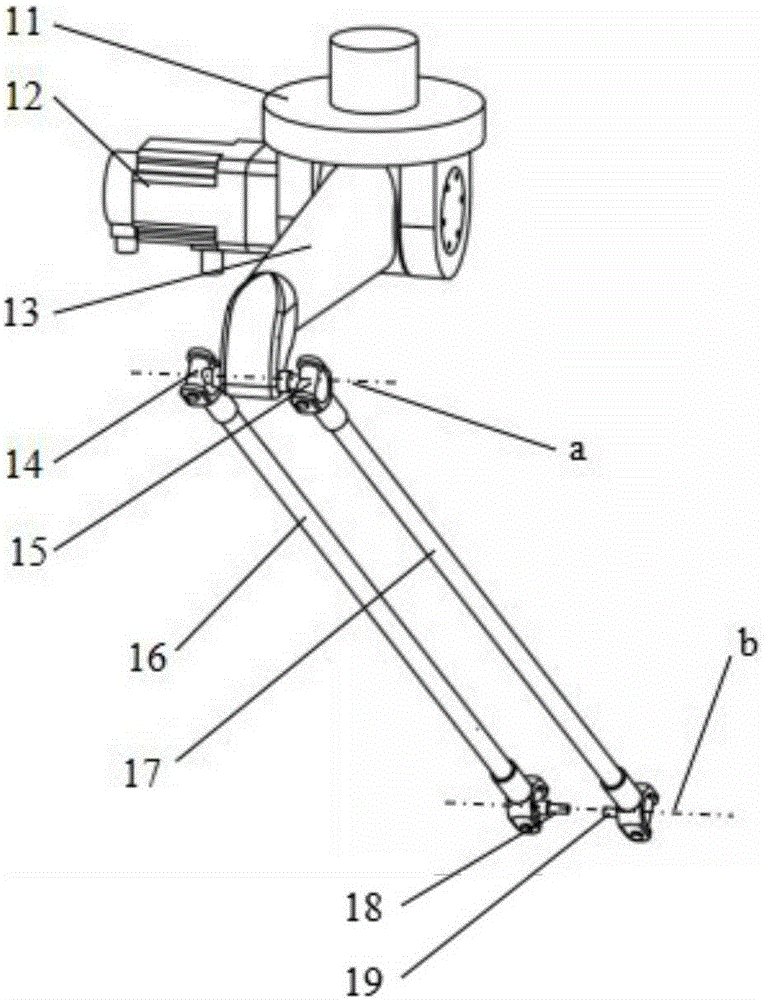

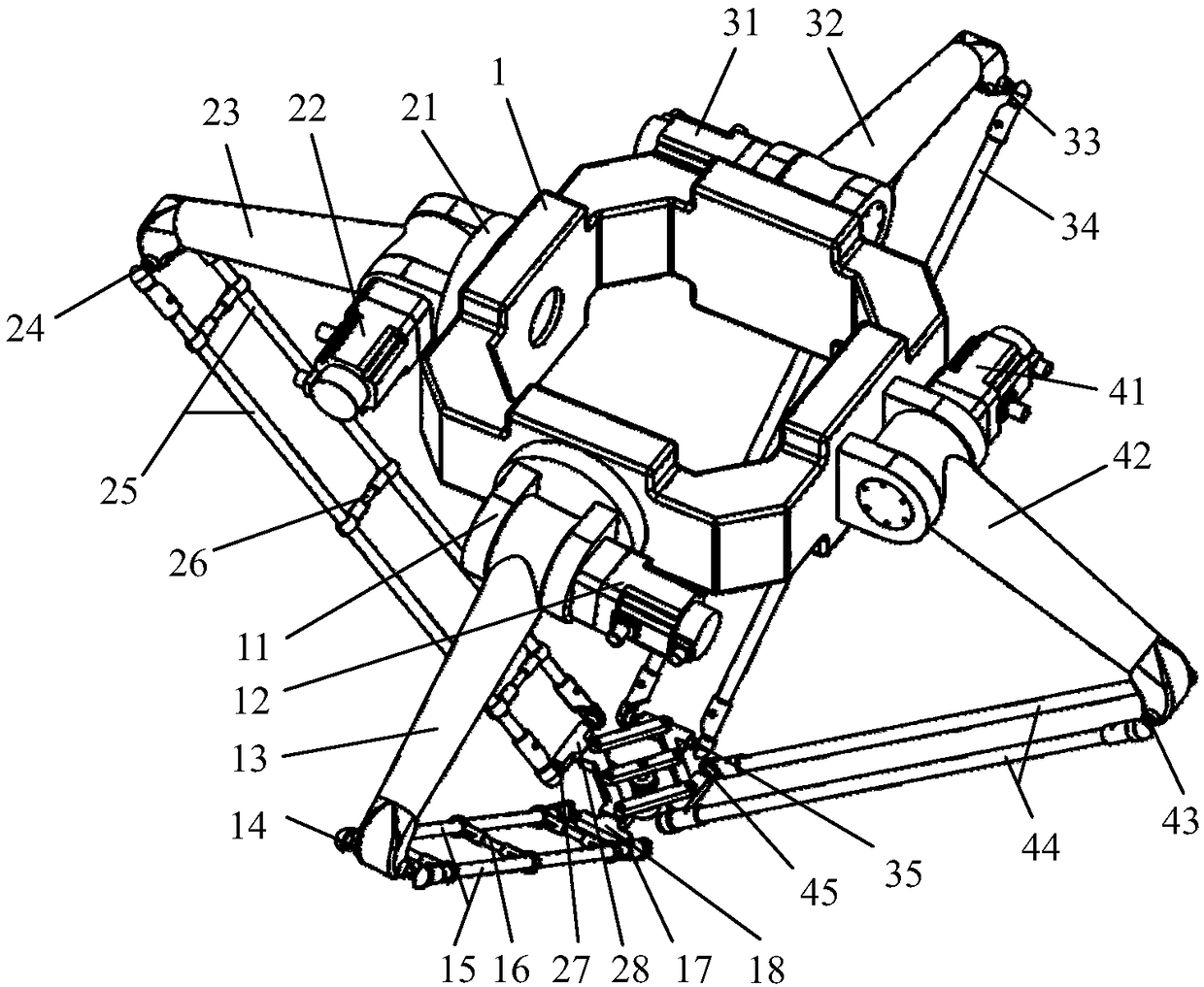

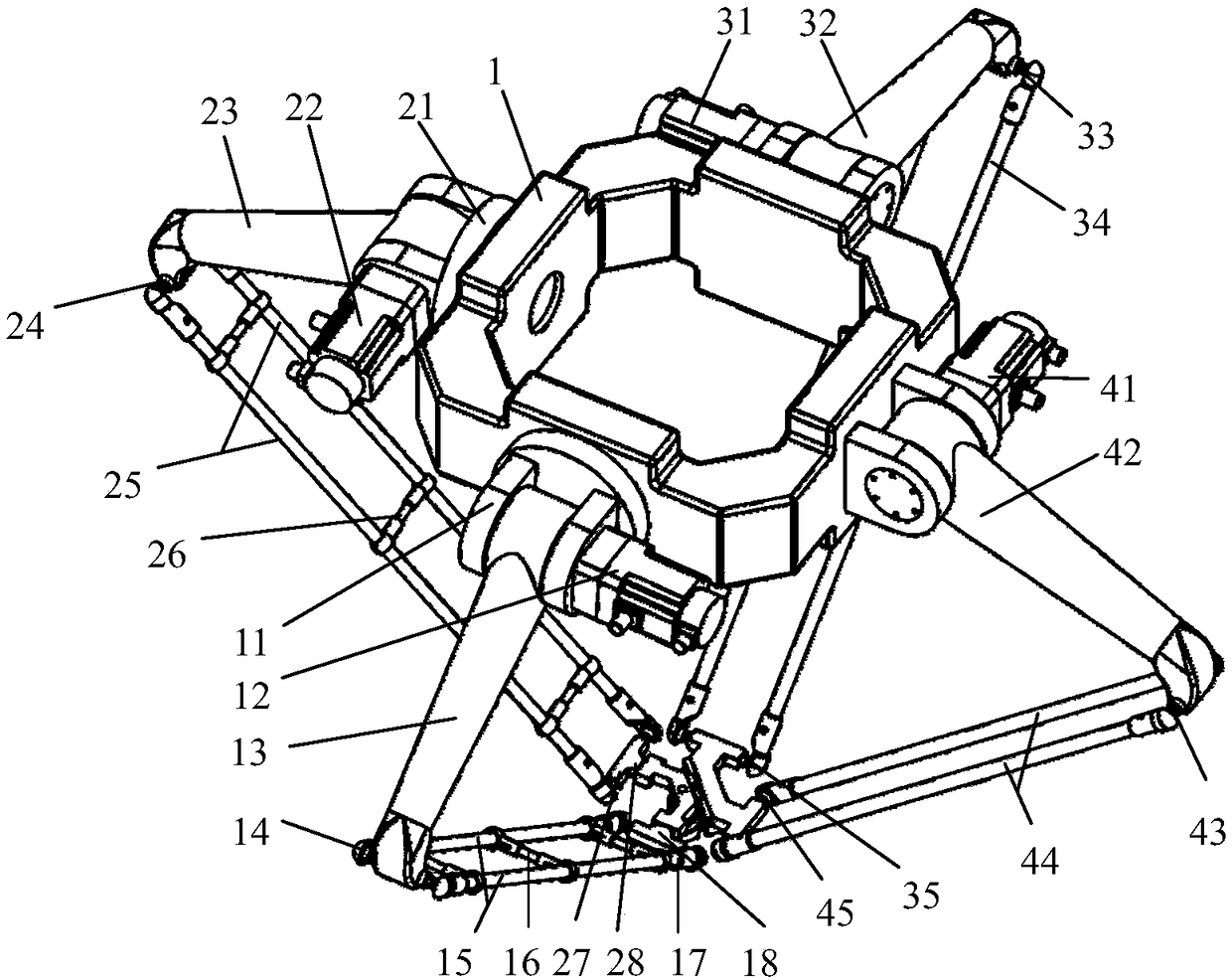

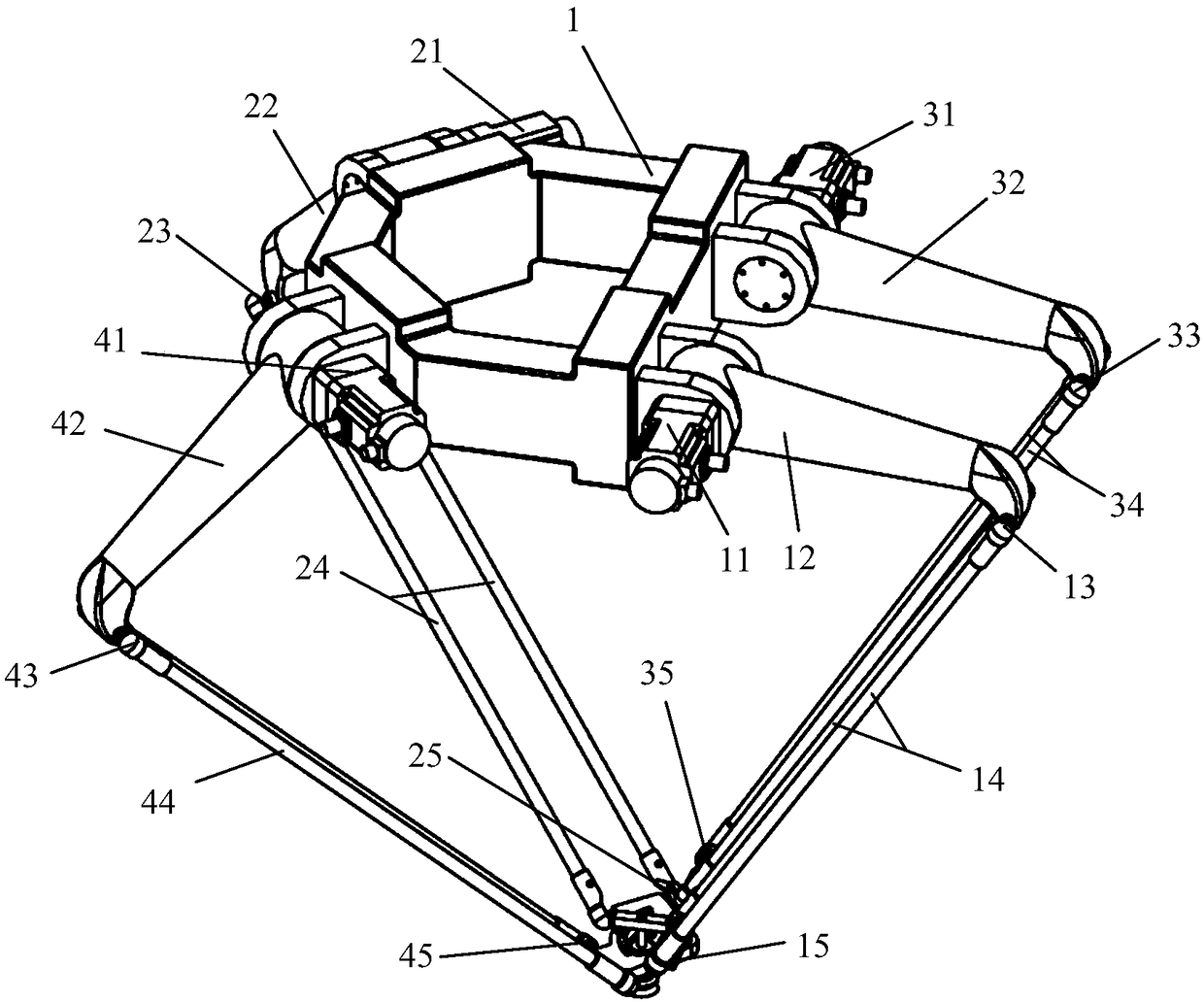

Four-freedom-degree high-speed parallel robot mechanism

ActiveCN106313004ACompact structureThe movement method is clearProgramme-controlled manipulatorRotational axisFixed frame

The invention discloses a four-freedom-degree high-speed parallel robot mechanism which comprises a fixed frame, a moving platform, a first branched chain, a second branched chain, a third branched chain and a fourth branched chain. The first branched chain, the second branched chain, the third branched chain and the fourth branched chain are arranged between the fixed frame and the moving platform. The first branched chain and the second branched chain each comprise a rotating fork, a close frame bar, two parallel and equilong far frame bars and a rotating shaft, wherein each rotating fork is rotationally connected with the fixed frame, one end of each close frame bar is rotationally connected with the corresponding rotating fork, the other end of each close frame bar is spherically hinged to the corresponding far frame bars, each far frame bar is spherically hinged to the corresponding rotating shaft, and each rotating shaft is rotationally connected with the moving platform. The third branched chain and the fourth branched chain each comprise a close frame bar and two parallel and equilong far frame bars, wherein one end of each close frame bar is rotationally connected with the fixed frame, the other end of each close frame bar is spherically hinged to the corresponding far frame bars, and each far frame bar is spherically hinged to the moving platform. The mechanism is ingenious in design and compact in structure and can adapt to complex grabbing and releasing environments.

Owner:NANJING UNIV OF SCI & TECH

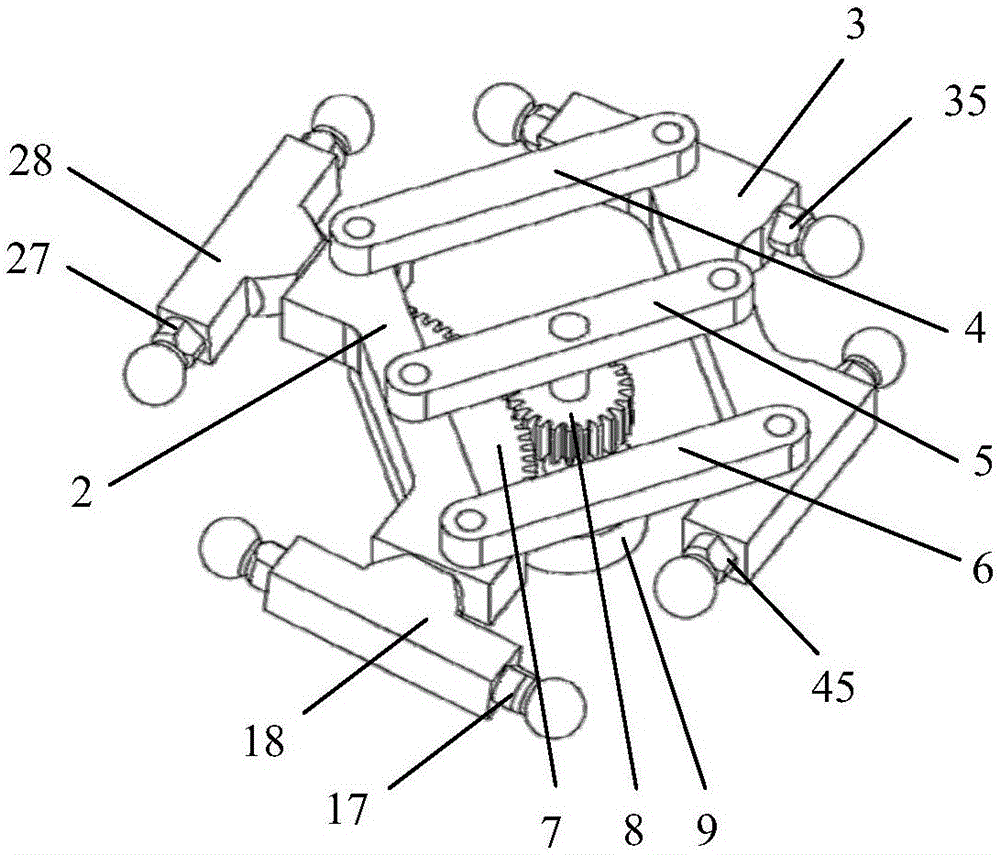

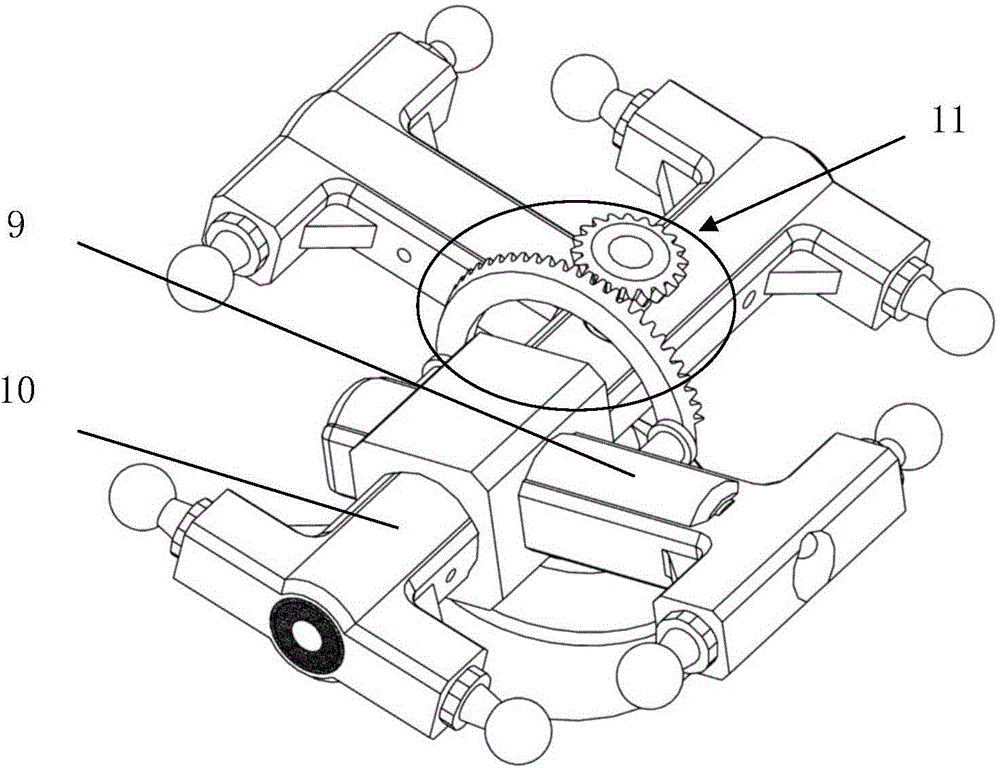

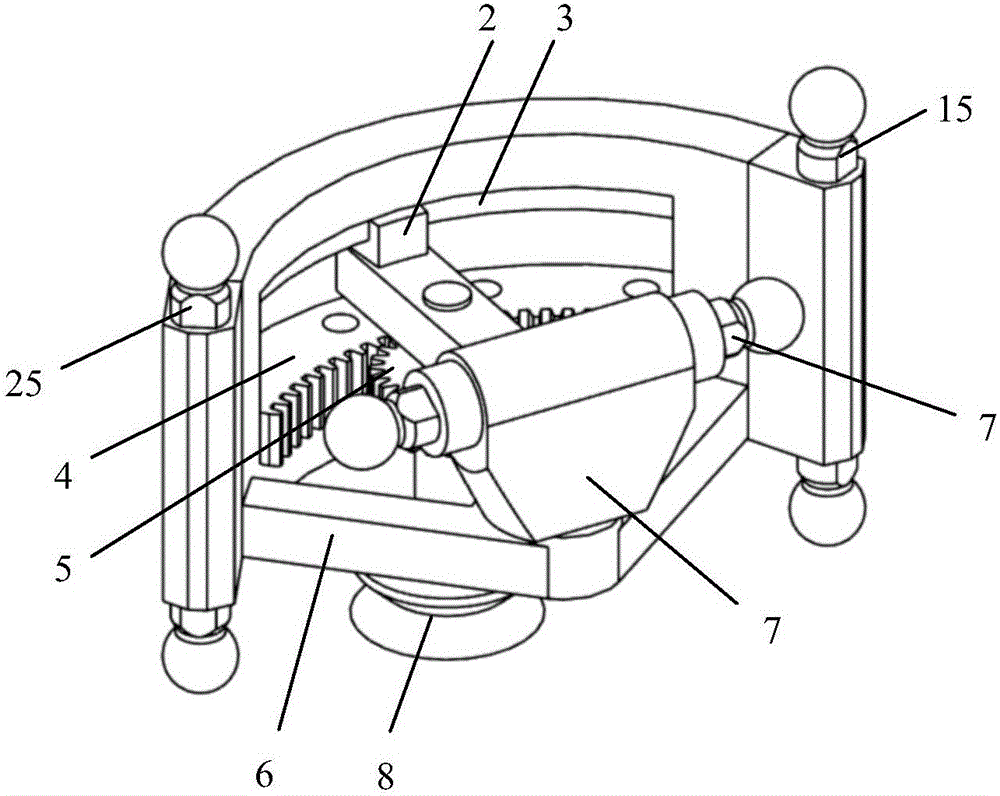

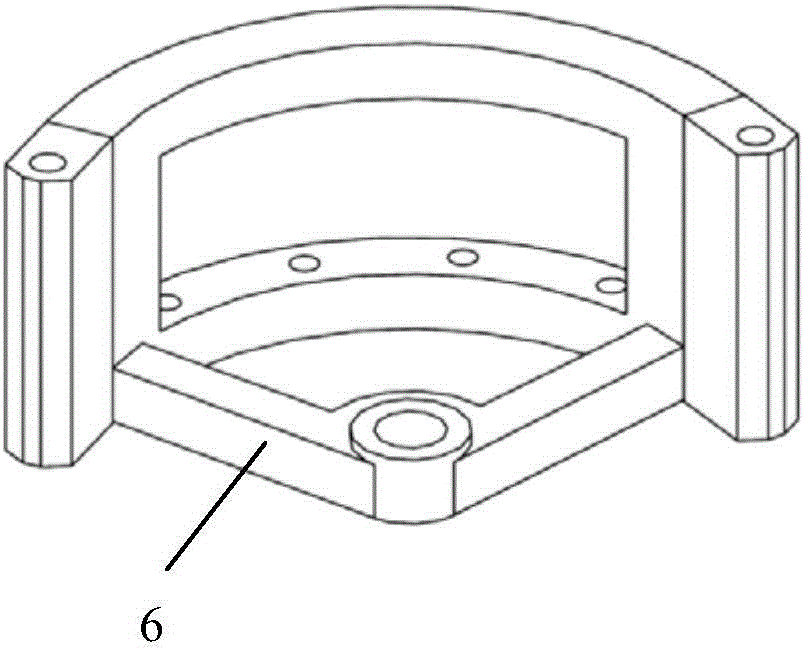

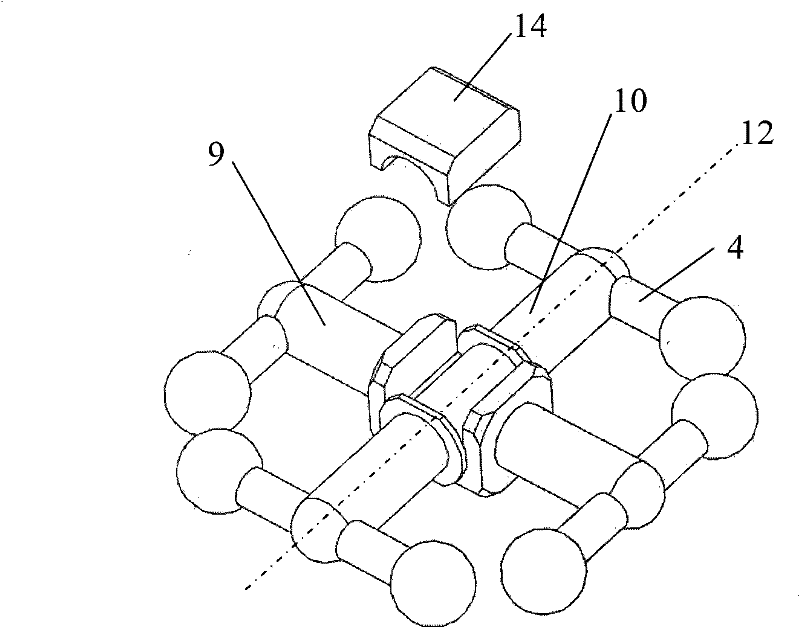

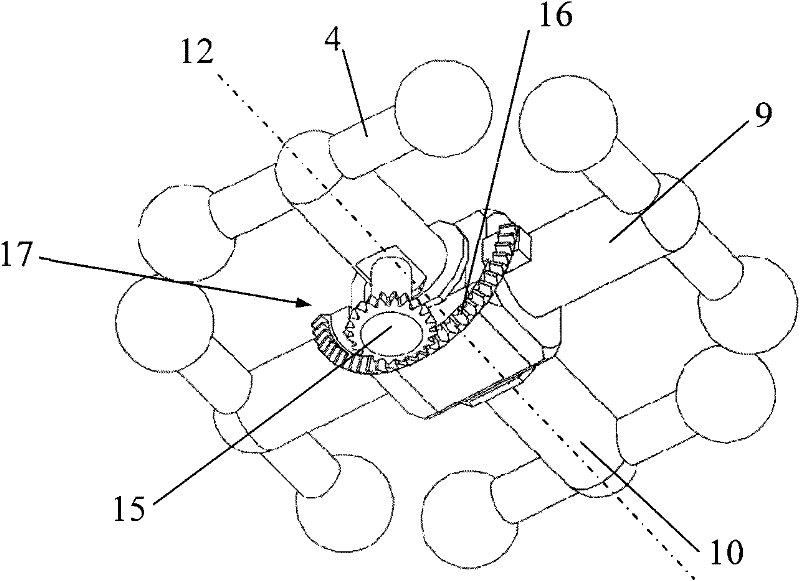

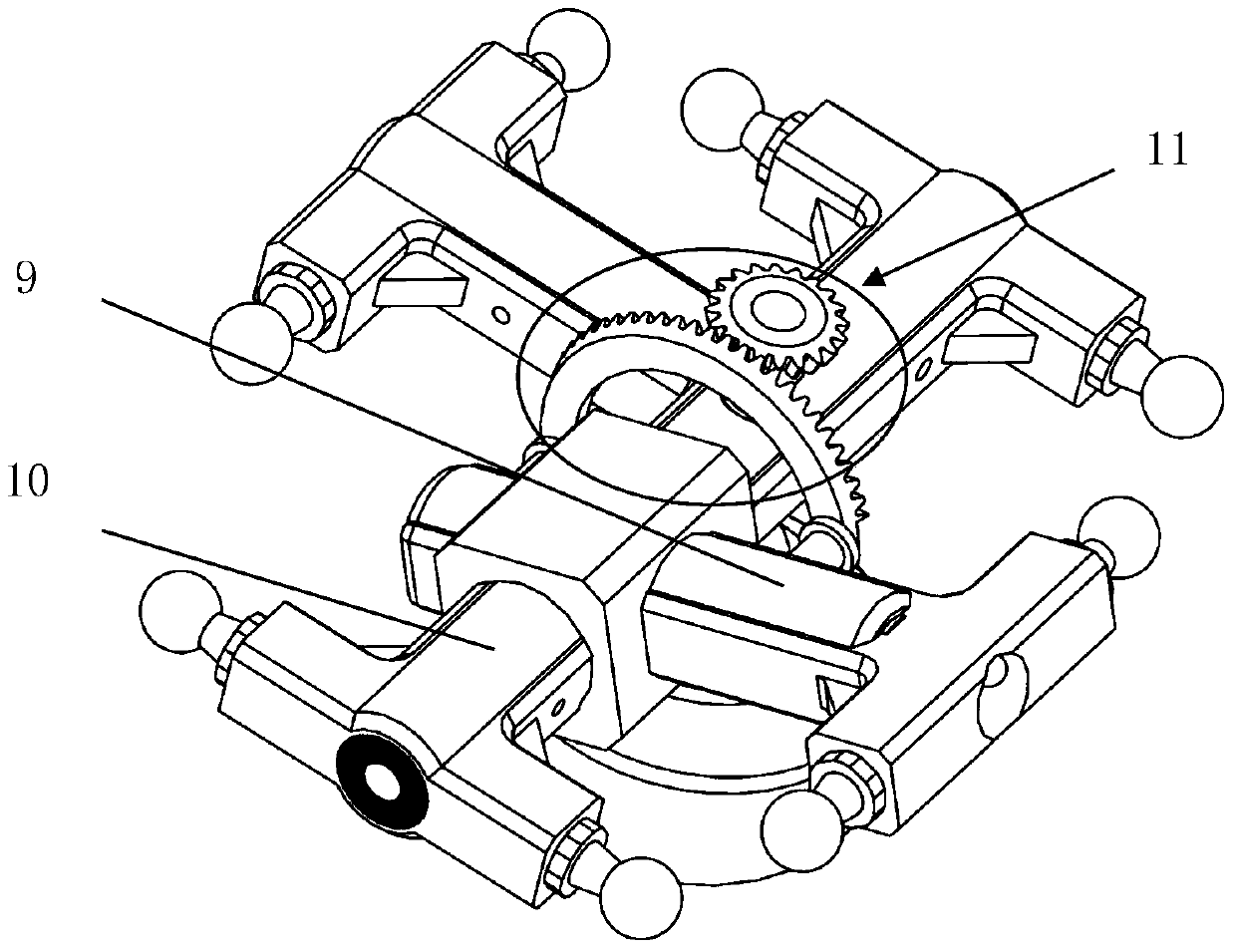

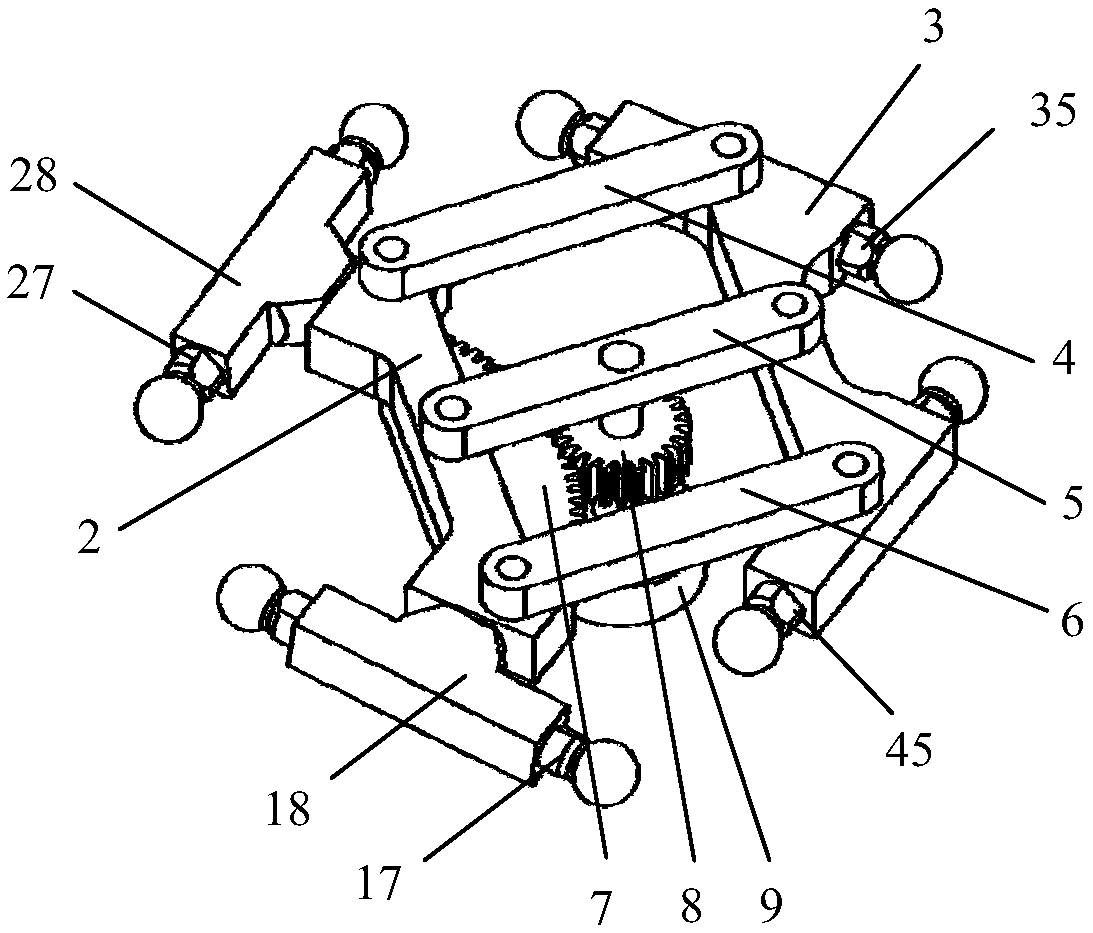

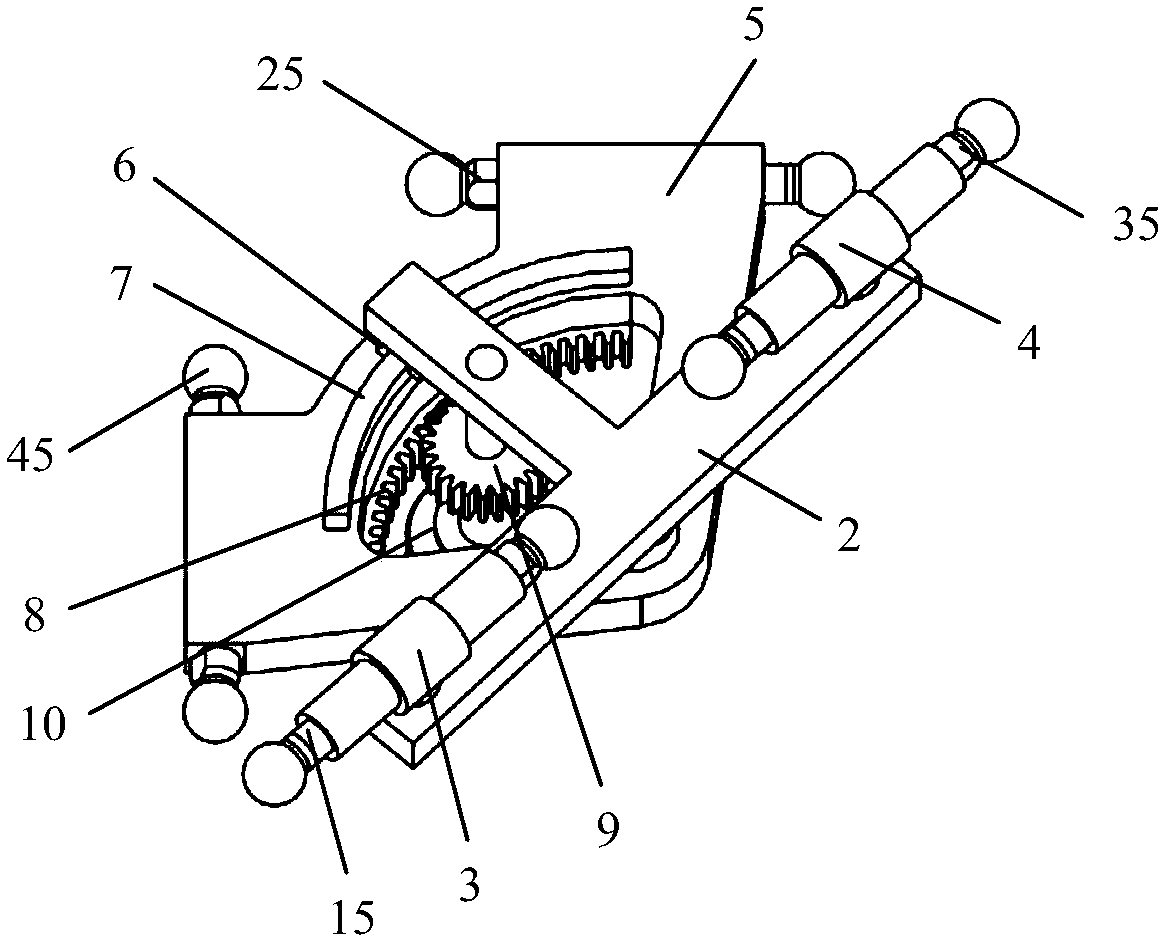

Four-degree-of-freedom parallel mechanism

ActiveCN105522559AClear division of laborSimple structureProgramme-controlled manipulatorFixed frameGear wheel

The invention relates to the technical field of automobile parts, in particular to a four-degree-of-freedom parallel mechanism. The four-degree-of-freedom parallel mechanism comprises a fixed frame, a movable platform and four branch chains. The branch chains are symmetrically arranged between the fixed frame and the movable platform and of the same structure. The movable platform is mainly composed of a main platform and a vice platform. The vice platform is connected with the main platform in a sleeving mode through a bevel gear pair. The axis of a big bevel gear of the bevel gear pair and the axis center of the main platform are coaxial, and the big bevel gear is fixed to one side of the vice platform. A small bevel gear of the bevel gear pair is installed on the main platform. The axis of the big bevel gear is perpendicular to the axis of the small bevel gear. An end effector is installed on the lower portion of the small bevel gear. The four-degree-of-freedom parallel mechanism is simple in structure and clear in motion mode. A large rotation angle range is obtained due to the large transmission ratio of the bevel gear pair, so that a magnification mechanism does not need to be used, and the motion speed is greatly increased.

Owner:CHENXING (TIANJIN) AUTOMATION EQUIP CO LTD

Free motion device

ActiveCN103192377AReduce volumeSimple structureProgramme-controlled manipulatorElectric machineryDrive motor

The invention provides a free motion device which comprises a base, at least one driving motor and at least one connecting rod, wherein a turning joint is arranged on the base, and a motion platform is supported through the turning joint; a swing arm is arranged on the output end of the driving motor, and driven to rotate during the rotation of the driving motor; and one end of the connecting rod is movably connected at the tail end of the swing arm, the other end of the connecting rod is movably connected to the other side of the motion platform, and the motion platform is driven by the swing arm to move around the turning joint. Two driving motors, two swing arms and two connecting rods can be arranged in a preferable embodiment of the invention, the swing arms drive the corresponding connecting rods to move, and the motion platform is further driven to move back and forth or sideways around the turning joint or move along the central axis of the turning joint. The free motion device has the characteristics of small volume, succinct structure, low cost, high precision, convenience in control and defined motion mode, makes the technical progress and achieves better motion effect.

Owner:深圳中智卫安机器人技术有限公司

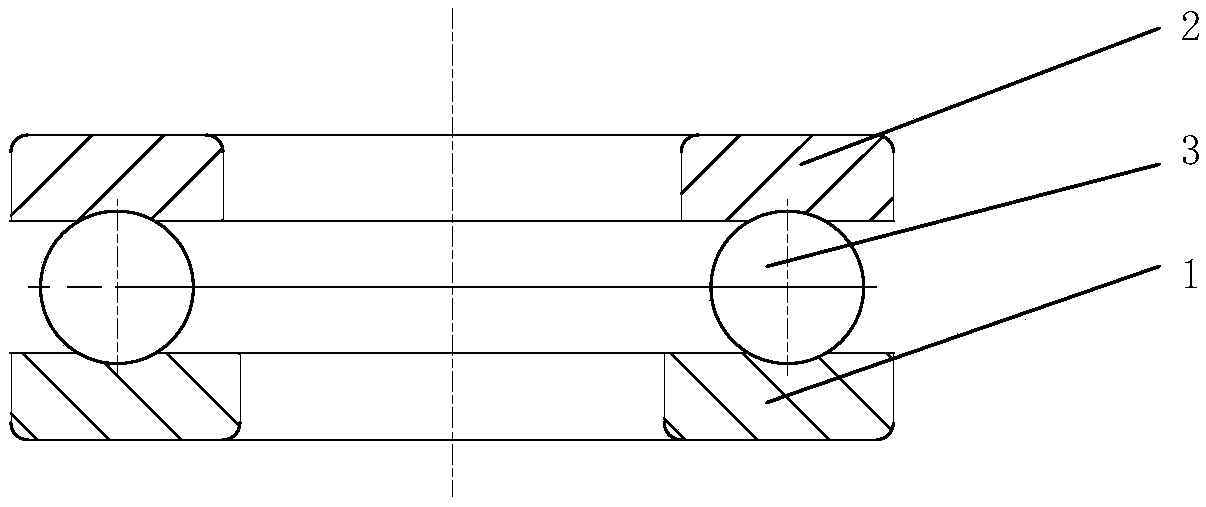

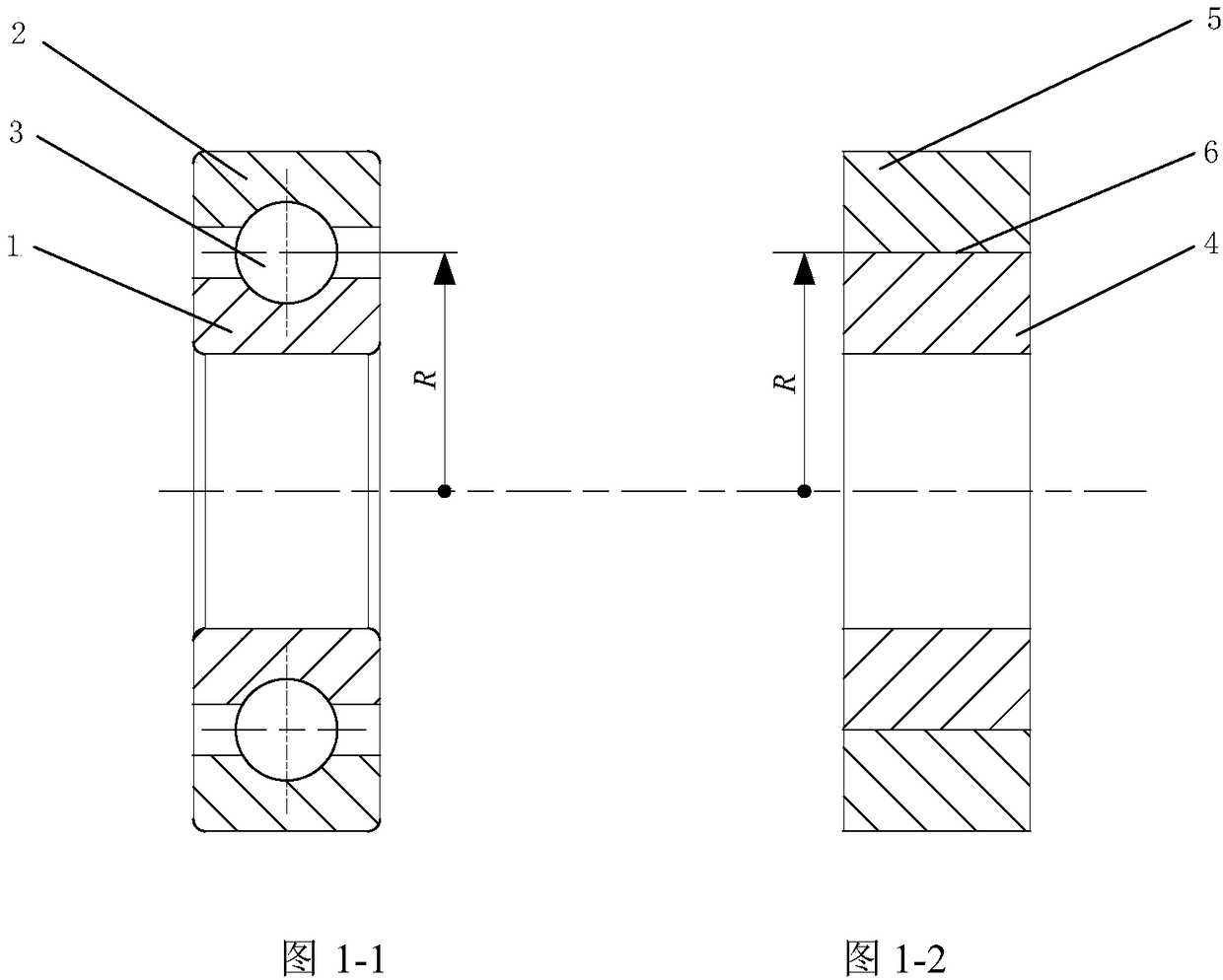

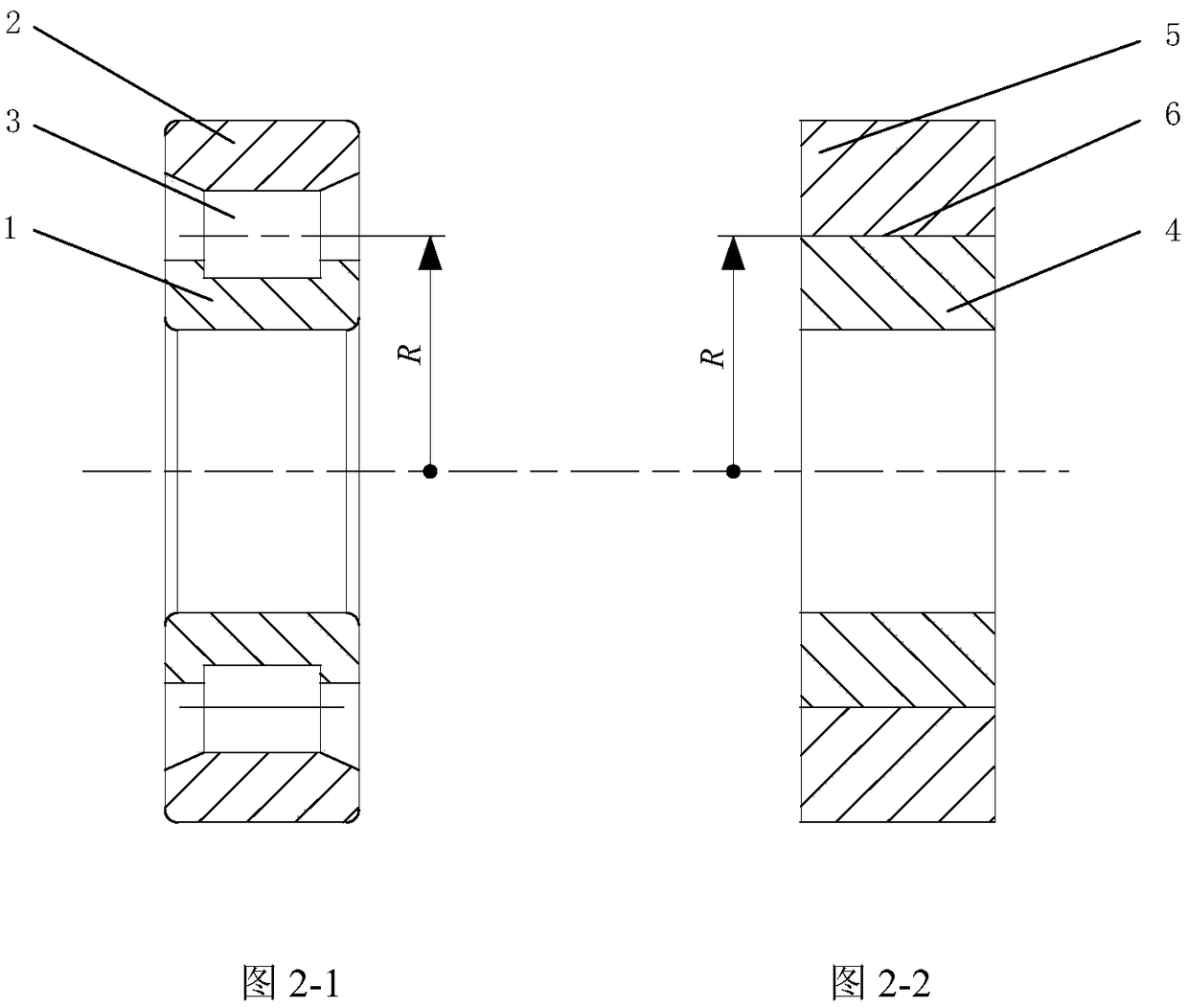

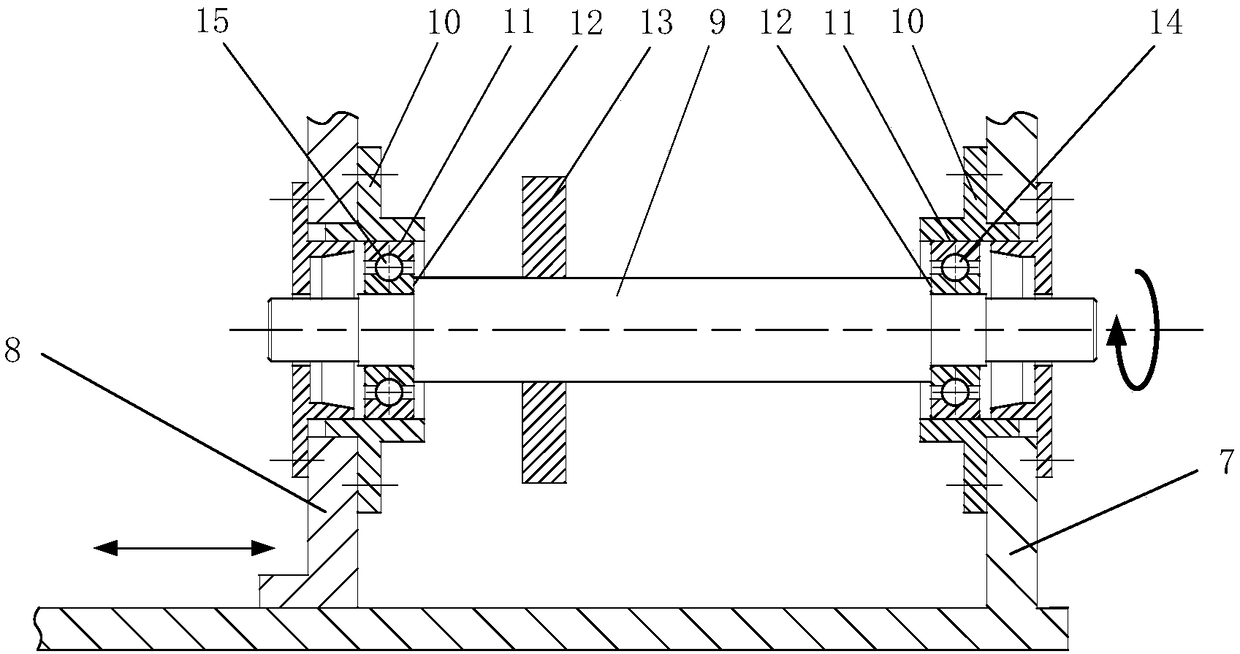

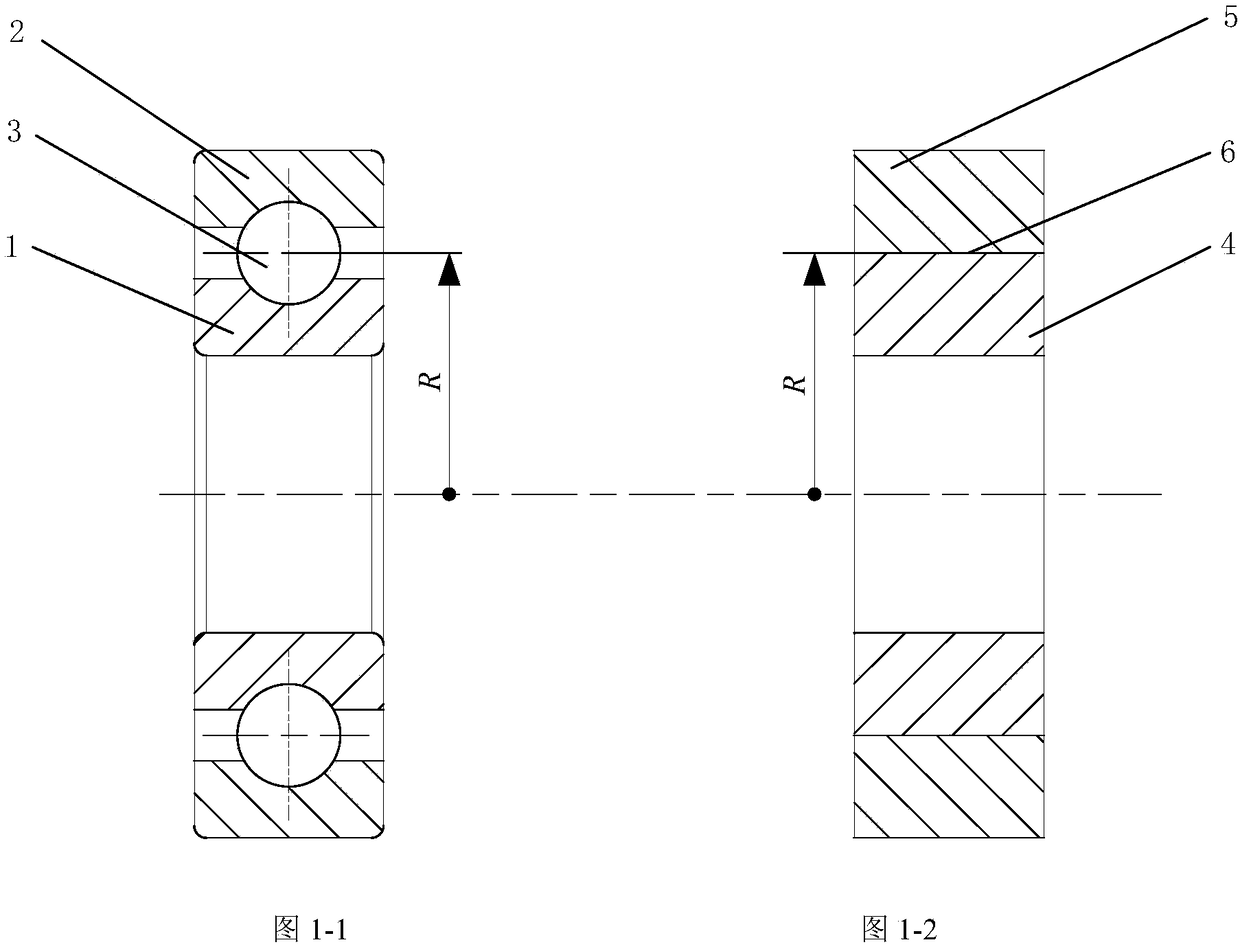

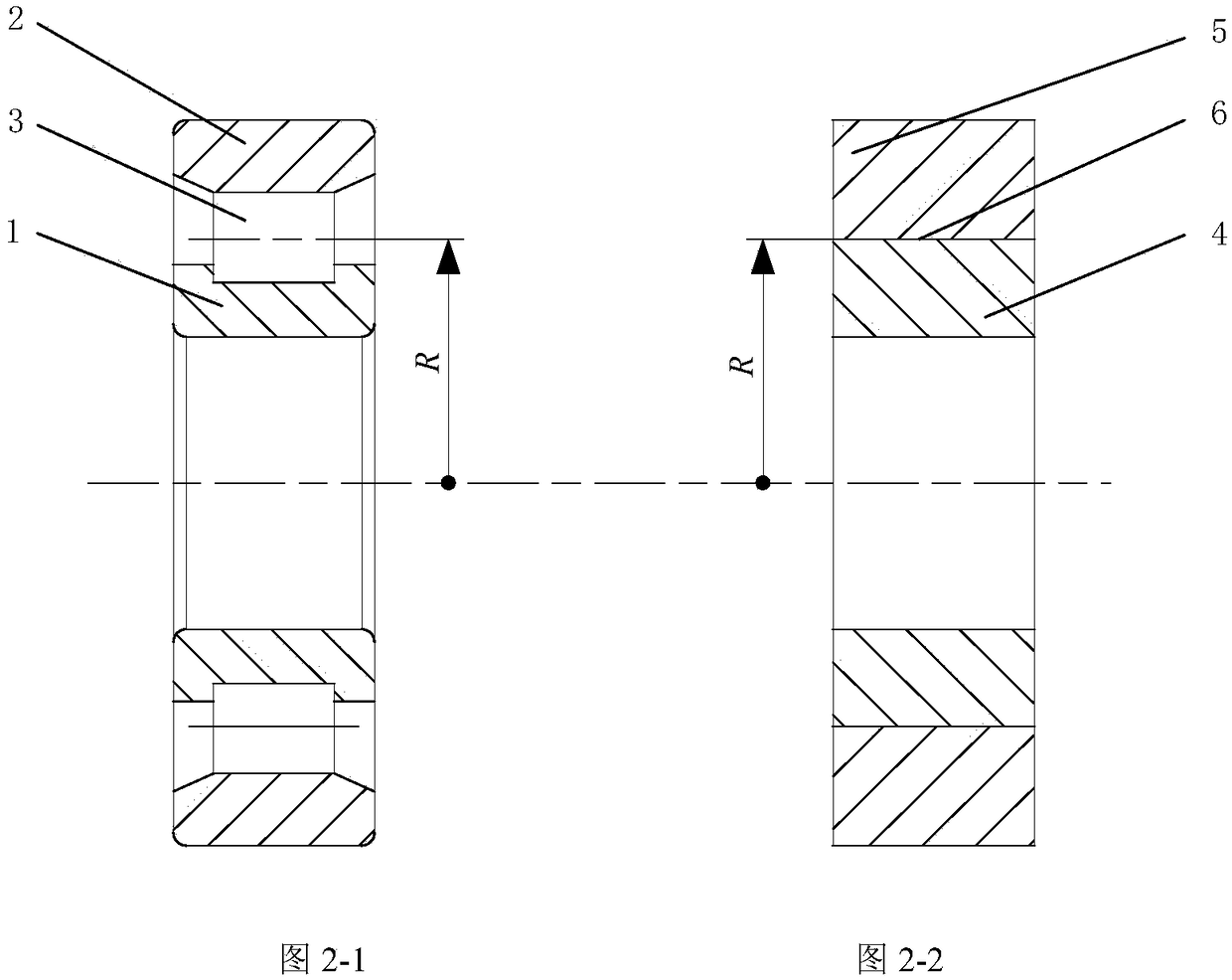

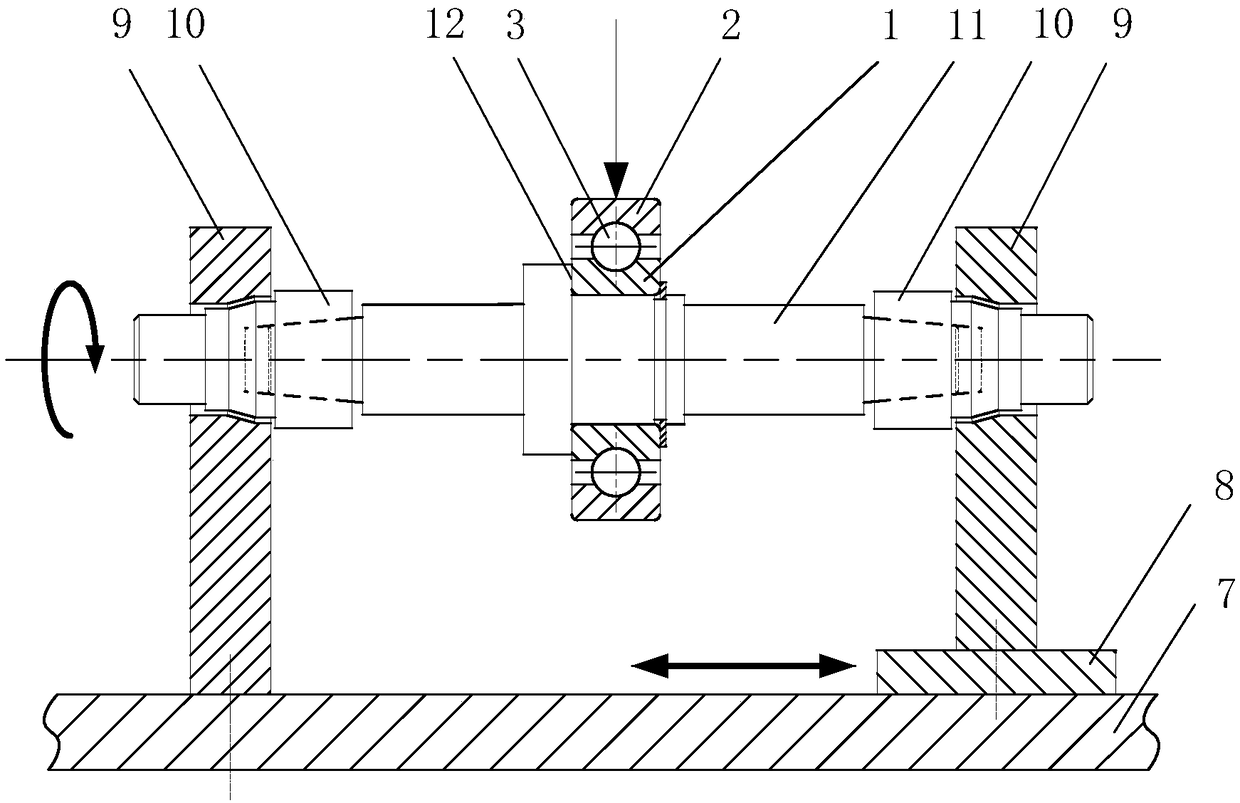

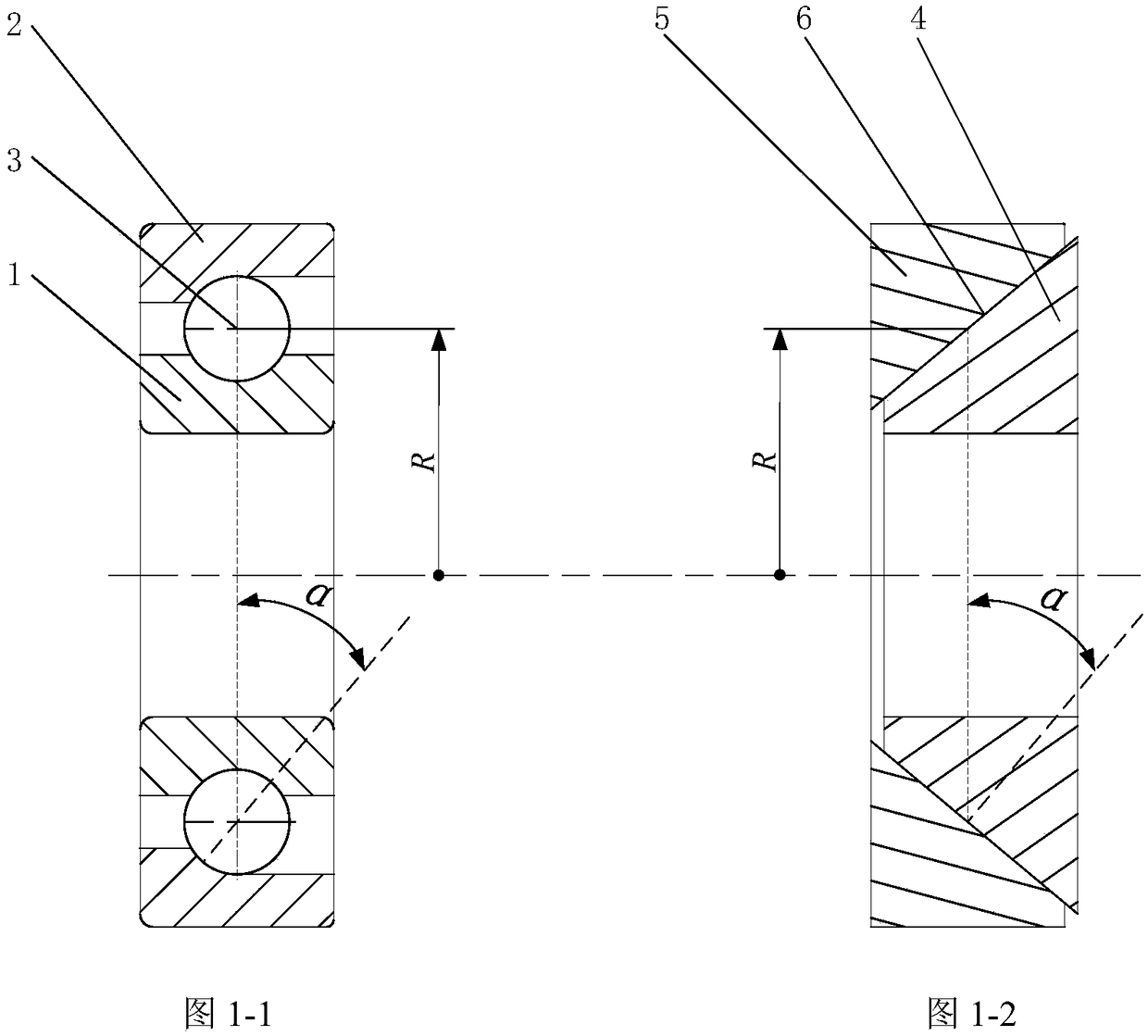

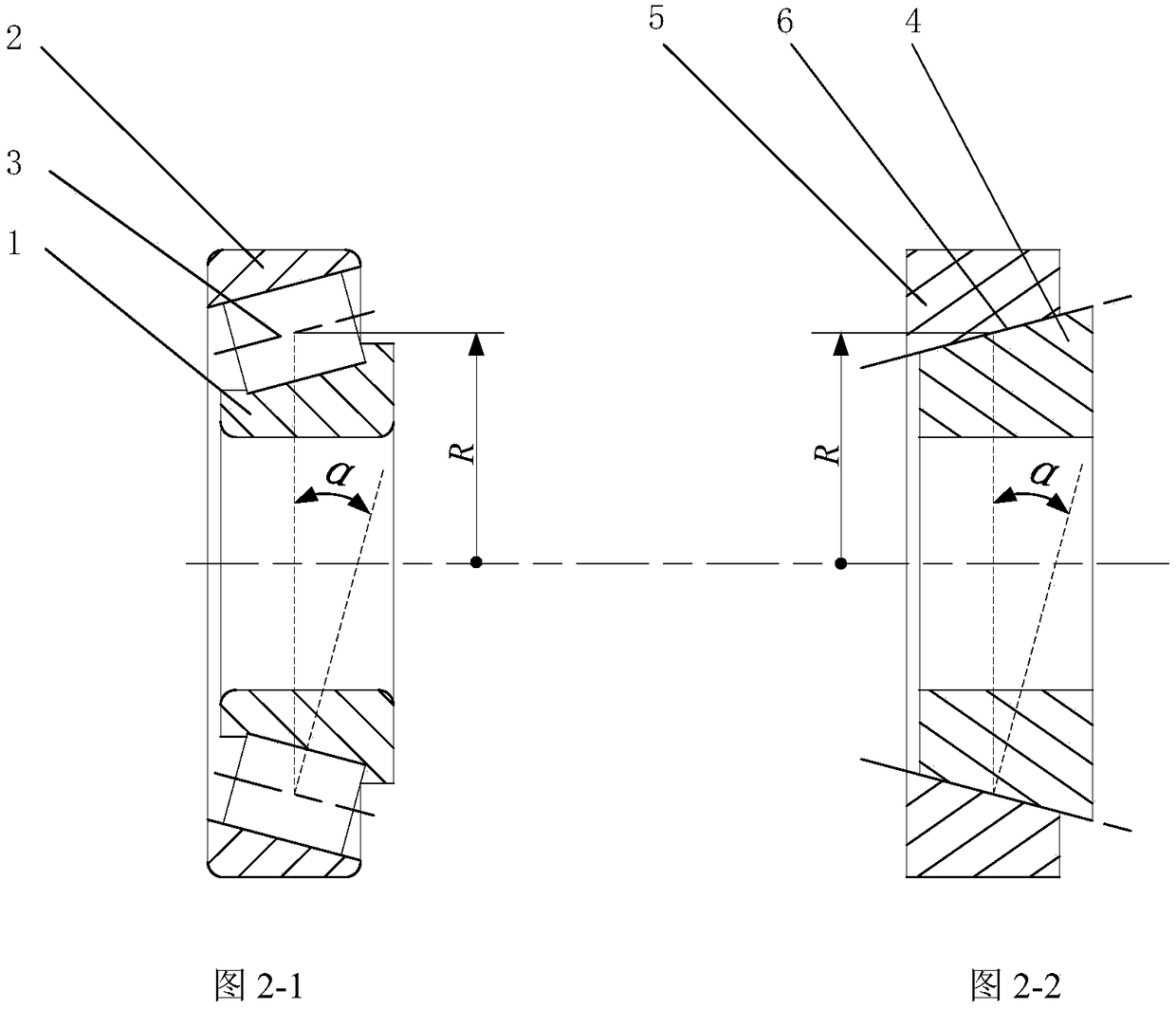

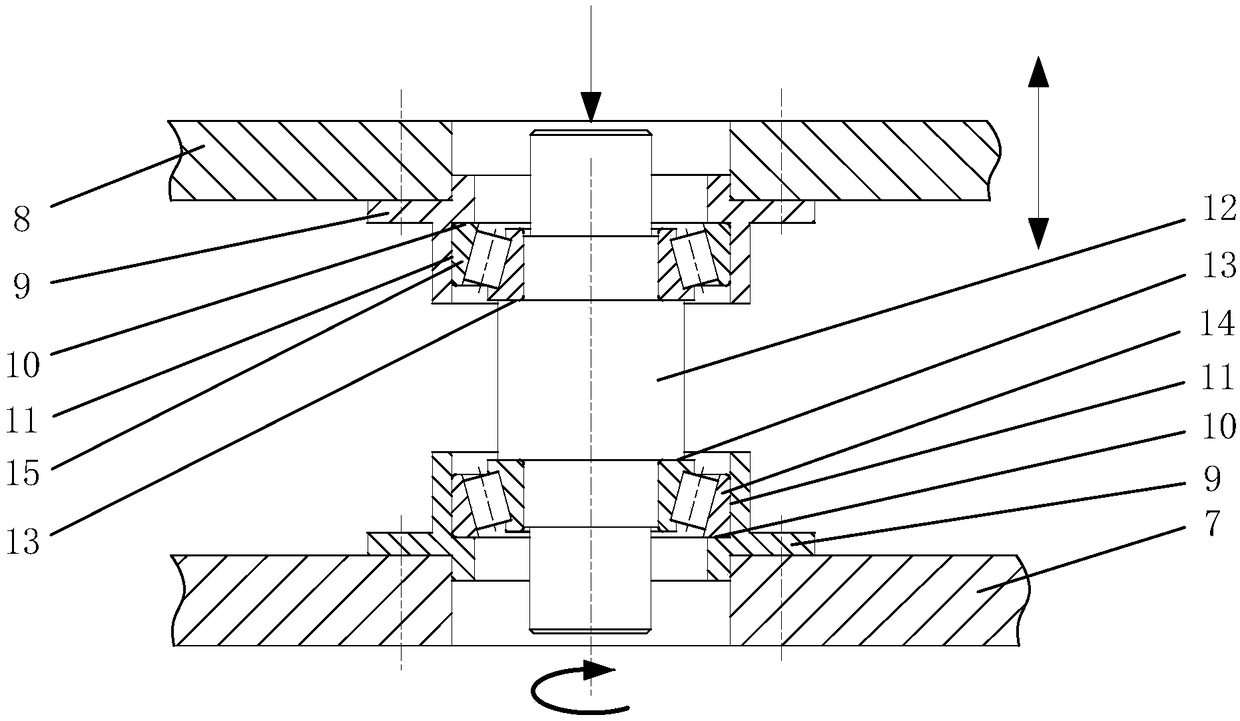

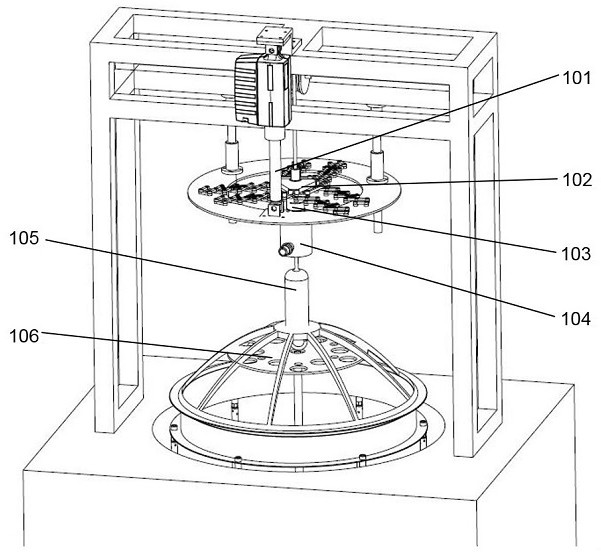

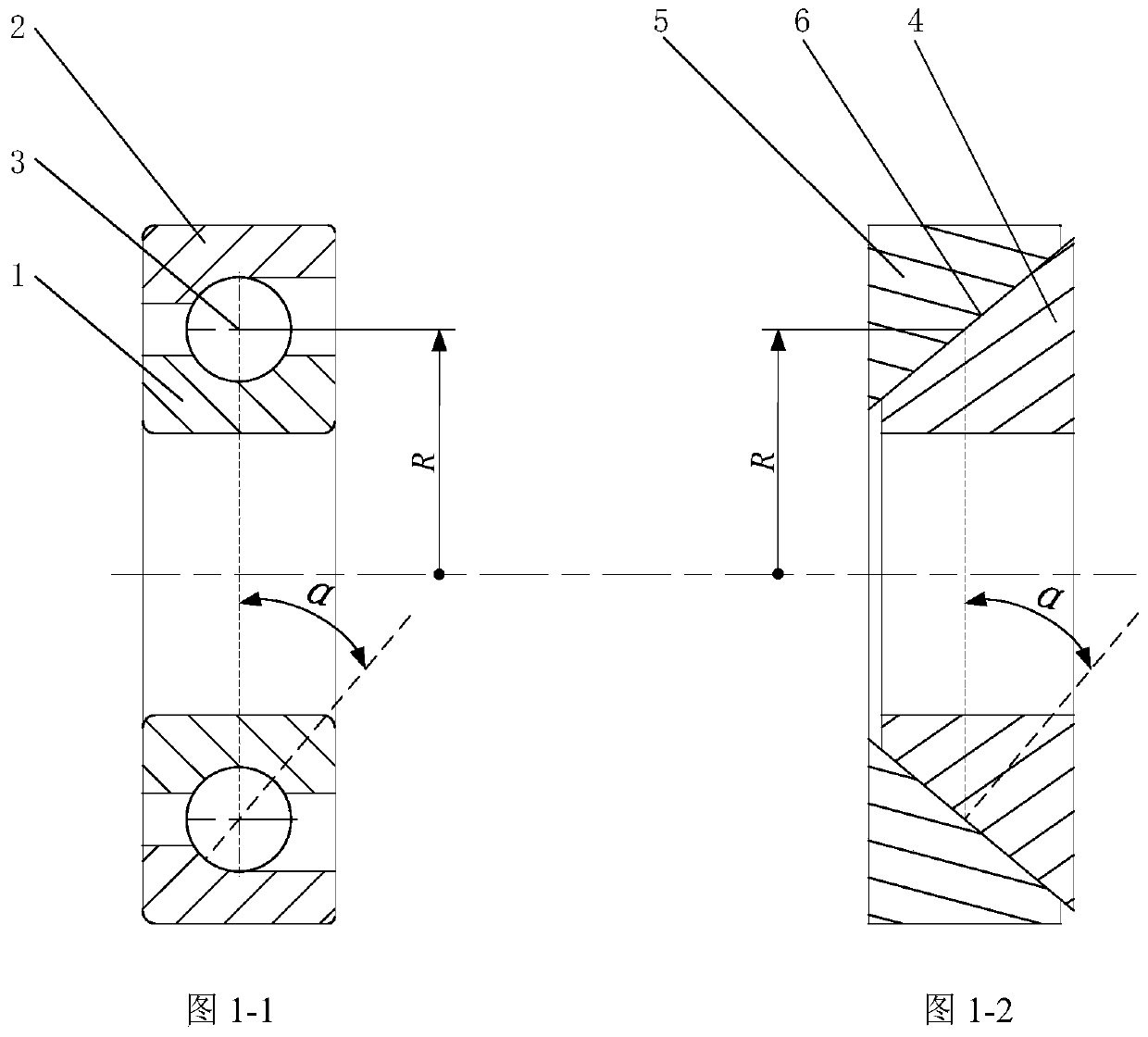

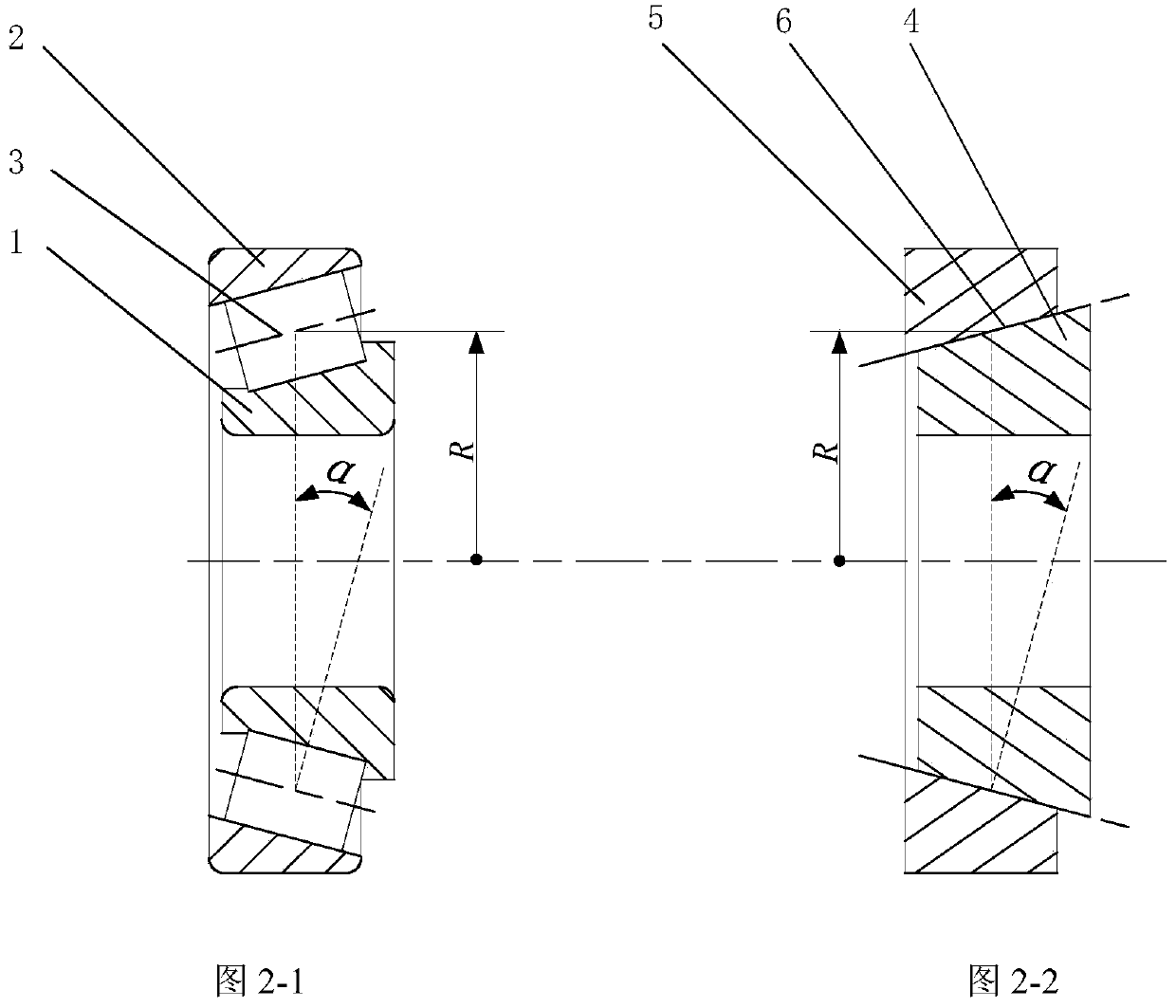

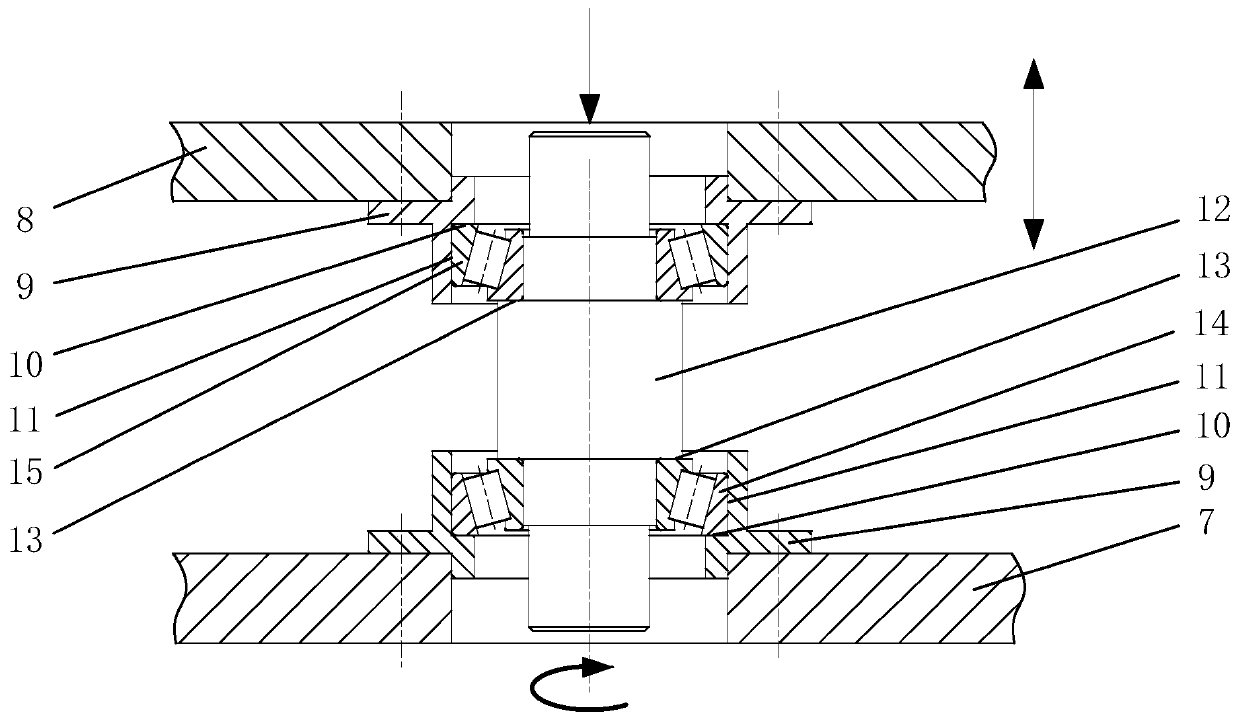

Equivalent friction coefficient measurement device and method of rolling bearing

PendingCN109540516AIncrease initial kinetic energyExtended decay timeMachine bearings testingSustainable transportationFriction torqueMeasurement device

The invention discloses an equivalent friction coefficient measurement device and method of a rolling bearing. The equivalent friction coefficient measurement device comprises a machine body, an air floating main shaft assembly, a core shaft, a sliding table, a bearing block, a rotating speed sensor and a data acquiring / processing / calculating / displaying system. The air floating main shaft assemblycomprises an air floating main shaft base body and an air floating main shaft. The air floating main shaft base body is fixedly connected with the machine body. The core shaft is fittingly connectedwith the air floating main shaft through a conical surface. The inner ring of a to-be-tested rolling bearing is arranged on the shaft shoulder of the core shaft. The outer ring of the to-be-tested rolling bearing is installed on the retaining shoulder of the bearing block. The bearing block is fixedly connected with the sliding table. The sliding table is capable of horizontally moving along the axial direction of the air floatation main shaft under the guiding effect of a guide component. The data acquiring / processing / calculating / displaying system is used for acquiring and processing the angular velocity signals of the core shaft or the air floating main shaft monitored by the rotating speed sensor, and then calculating the equivalent friction torque and the equivalent friction coefficient of the to-be-tested rolling bearing. The measurement device has the capability of rapidly and precisely measuring the equivalent friction torque and the equivalent friction coefficient of the rolling bearing.

Owner:TIANJIN UNIV

Three-transverse-movement parallel mechanism

InactiveCN105234925ACompact structureThe movement method is clearProgramme-controlled manipulatorMechanical engineeringEngineering

Owner:NANJING UNIV OF SCI & TECH

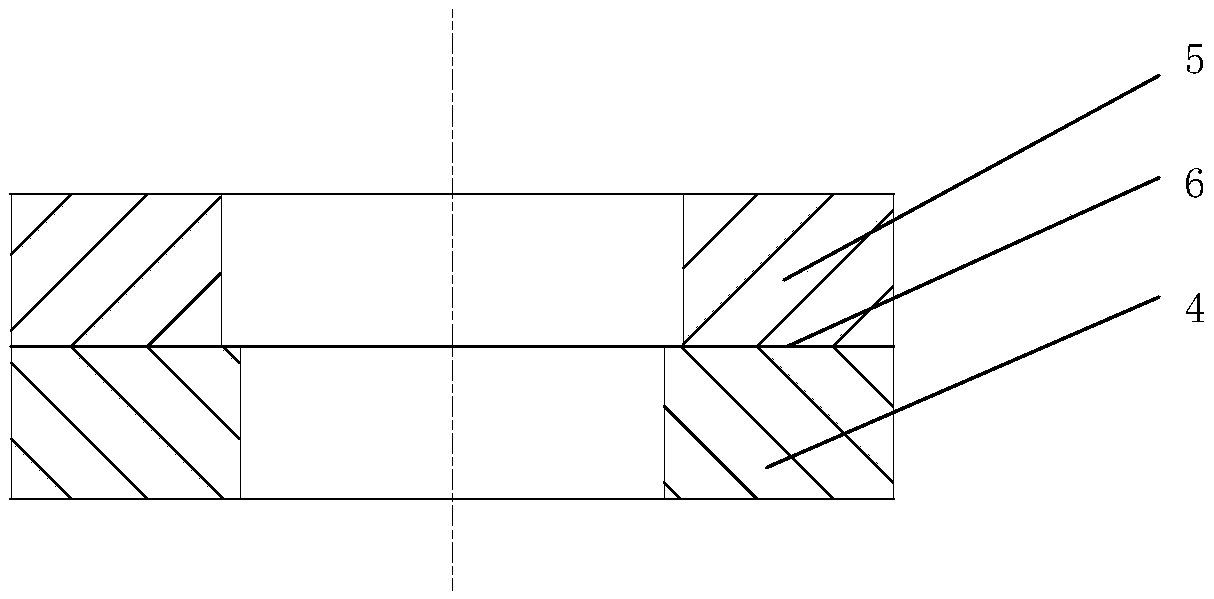

Vertical rolling bearing equivalent friction coefficient measuring device and method

ActiveCN109238708AImprove calculation accuracyHigh measurement/calculation accuracyMachine bearings testingFriction torqueRolling-element bearing

The invention discloses a vertical rolling bearing equivalent friction coefficient measuring device. The vertical rolling bearing equivalent friction coefficient measuring device comprises a machine body, a sliding seat, a mandrel, two bearing pedestals, an annular counterweight part, a rotating speed sensor and a data acquisition / processing / calculation / display device; one bearing pedestal is fixedly connected with the machine body, and the other one is fixedly connected with the sliding seat; the two bearing pedestals are provided with inner cylindrical surfaces matched with the outer rings of tested rolling bearings respectively; the two inner cylindrical surfaces are coaxial; the two ends of the mandrel are provided with shaft shoulders used for mounting the inner rings of the tested rolling bearings respectively; the mandrel is provided with the annular counterweight part; the sliding seat axially and horizontally moves along the inner cylindrical surfaces of the two bearing pedestals under external force driving; the data acquisition / processing / calculation / display device is used for collecting and processing the angular speed signal, monitored by the rotating speed sensor, ofthe mandrel, and calculating the equivalent friction torque and equivalent friction coefficient of an tested rolling bearing and a B tested rolling bearing. The measuring device has the capability ofrapidly and precisely measuring the equivalent friction torque and equivalent friction coefficient of the rolling bearing.

Owner:TIANJIN UNIV

Three-freedom-degree robot mechanism capable of translating in two directions and rotating in one direction

ActiveCN106272361ACompact structureThe movement method is clearProgramme-controlled manipulatorEngineeringDegrees of freedom

The invention discloses a three-freedom-degree robot mechanism capable of translating in two directions and rotating in one direction. The three-freedom-degree robot mechanism capable of translating in two directions and rotating in one direction comprises a fixed frame, a moving platform, and a first branched chain, a second branched chain and a third branched chain which are arranged between the fixed frame and the moving platform; each of the three branched chains comprises a near frame rod and two parallel far frame rods with equal lengths; the third branched chain also comprises a converting fork; the converting fork is fixedly connected with the fixed frame; one end of the near frame rod is connected with the fixed frame or the converting fork; the other end of the near frame rod is spherically hinged to the far frame rod; the far frame rod is spherically hinged to the moving platform; the moving platform comprises a primary platform and a secondary platform which can rotate relatively; the mechanism is high in rigidity, flexible in movement, and can realize high-speed grasping and releasing.

Owner:NANJING UNIV OF SCI & TECH

Parallel mechanism with three-dimensional translation and one-dimensional rotation

InactiveCN101708611BIncrease stiffnessSimple structureProgramme-controlled manipulatorMechanical apparatusFixed frameRotational degrees of freedom

Owner:TIANJIN UNIV

Equivalent friction coefficient measurement device and method of rolling bearing

ActiveCN109238709AHigh measurement/calculation accuracyAccurate measurement accuracyMachine bearings testingFriction torqueMeasurement device

The invention discloses an equivalent friction coefficient measurement device and method of a rolling bearing. The equivalent friction coefficient measurement device comprises a machine body, a sliding seat, two air flotation main shaft assemblies, a core shaft, a rotational speed sensor and a data acquisition / processing / calculation / display system, wherein each air flotation main shaft assembly comprises an air flotation main shaft matrix and an air flotation main shaft, one of the air flotation main shaft matrixes is fixedly connected with the machine body, the other one air flotation main shaft matrix is fixedly connected with the sliding seat, the two air flotation main shafts are coaxial, two ends of the core shaft are matched or connected with the two air flotation main shafts by conical surfaces or couplers, an inner circle of a measured rolling bearing is arranged at a shaft shoulder of the core shaft, the rotational speed sensor is used for monitoring angular speeds of the coreshaft or the air floatation main shafts, and the data acquisition / processing / calculation / display system is used for acquiring and processing angular speed signals, monitored by the rotational speed sensor, of the core shaft or the air flotation main shafts and calculating equivalent friction torque and an equivalent friction coefficient of the measured rolling bearing. The measurement device hasthe capability of rapidly and accurately measuring the equivalent friction torque and the equivalent friction coefficient of the rolling bearing.

Owner:TIANJIN UNIV

Four-freedom-degree robot mechanism capable of achieving three-dimensional translation and one-dimensional rotation

ActiveCN106313005ACompact structureThe movement method is clearProgramme-controlled manipulatorManufacturing cost reductionEngineering

The invention discloses a four-freedom-degree robot mechanism capable of achieving three-dimensional translation and one-dimensional rotation. The four-freedom-degree robot mechanism comprises a fixed frame, a moving platform, a first branched chain, a second branched chain and a third branched chain. The first branched chain, the second branched chain and the third branched chain are arranged between the fixed frame and the moving platform. The three branched chains each comprise a close frame bar and two parallel and equilong far frame bars. The third branched chain further comprises a rotating fork, and the rotating fork is rotationally connected with the fixed frame. One end of each close frame bar is connected with the fixed frame or the rotating fork, the other end of each close frame bar is spherically hinged to the corresponding far frame bars, and each far frame bar is spherically hinged to the moving platform. The moving platform comprises a main platform body and an auxiliary platform body which are rotationally connected. According to the mechanism, four-freedom-degree motion of three-dimensional translation and one-dimensional rotation is achieved through the three branched chains, and the manufacturing cost can be reduced easily.

Owner:NANJING UNIV OF SCI & TECH

Parallel mechanism with two-dimensional translation and two-dimensional rotation

The invention discloses a parallel mechanism with two-dimensional translation and two-dimensional rotation. The parallel mechanism comprises a fixed frame, a moving platform and four branched chains which are symmetrically arranged between the fixed frame and the moving platform and provided with a drive device respectively, wherein the four branched chains have two types of structures; the branched chain with one type of structure comprises a straight line guide rail, a drive block arranged in the straight line guide rail and a fixed-length connecting rod of which both ends are provided withrotary hinges; the branched chain with the other type of structure comprises a straight line guide rail, a drive block arranged in the straight line guide rail and a fixed-length connecting rod of which both ends are provided with spherical hinges; the four branched chains with the two types of structures are in crossed arrangement; one end of the fixed-length connecting rod is connected with themoving platform, and the other end of the fixed-length connecting rod is connected with the drive block; and the moving platform is connected with a main platform and a fork-shaped shaft, of which the axial lines are vertical to each other, by a rotary pair, and the main platform can rotate around the axial line of the fork-shaped shaft. The parallel mechanism has the advantages that: the structure is simple; the mode of motion is definite; the requirements on complicated holding-releasing operations are met; and because the connecting rod is the fixed length rod which helps to reduce the inertia load, the parallel mechanism has higher rigidity in different operational ranges, and the high-speed movement is easily realized.

Owner:TIANJIN UNIV

Four-degree-of-freedom parallel robot mechanism

InactiveCN110695962ACompact structureThe movement method is clearProgramme-controlled manipulatorRotational axisControl theory

The invention discloses a four-degree-of-freedom parallel robot mechanism. The mechanism comprises a fixed frame, a movable platform and first, second, third and fourth branches arranged between the fixed frame and the movable platform; the first and second branches each comprise a rotating fork, a near-frame rod, two parallel and equal-length far-frame rods, and a rotating shaft, wherein the rotating fork is rotationally connected with the fixed frame, one end of the near-frame rod is rotatably connected with the rotating fork, the other end of the near-frame rod is connected with the far-frame rod by a spherical hinge, the far-frame rod is connected with the rotating shaft by a spherical hinge, and the rotating shaft is rotationally connected with the movable platform; and the third andfourth branched branches each comprise a rotating fork, a near-frame rod, two parallel and equal-length far-frame rods, wherein the rotating fork is rotationally connected with the fixing frame, one end of the near-frame rod is rotationally connected with the rotating fork, and the other end of the near-frame rod is connected with the farframe rod by a spherical hinge, and the far-frame rod is connected with the movable platform by a spherical hinge. The mechanism is ingenious in design and compact in structure, and can adapt to complex grasping and releasing environments.

Owner:NANJING UNIV OF SCI & TECH

Vertical rolling bearing equivalent friction coefficient measuring device and method

ActiveCN109238707AHigh measurement/calculation accuracyAccurate measurement accuracyMachine bearings testingFriction torqueRolling-element bearing

The invention discloses a vertical rolling bearing equivalent friction coefficient measuring device. The vertical rolling bearing equivalent friction coefficient measuring device comprises a machine body, a sliding table, a mandrel, two bearing pedestals, a rotating speed sensor and a data acquisition / processing / calculation / display device, wherein one of the bearing pedestals is fixedly connectedwith the machine body, and the other one is fixedly connected with the sliding table; an A to-be-tested rolling bearing outer ring is arranged on a bearing pedestal shoulder which is fixedly connectedwith the machine body, and a B to-be-tested rolling bearing outer ring is arranged on a bearing pedestal shoulder which is fixedly connected with the sliding table; an A to-be-tested rolling bearinginner ring is arranged on the shaft shoulder at one end of the mandrel, and a B to-be-tested rolling bearing inner ring is arranged on the shaft shoulder at the other end of the mandrel; the sliding table is capable of horizontally moving along the axial direction of the inner cylindrical surface of the bearing pedestals under the guide of a guide component; and the data acquisition / processing / calculation / display device is used for collecting and processing the angular speed signal, monitored by the rotating speed sensor, of the mandrel, and calculating the equivalent friction torque and equivalent friction coefficient of the tested rolling bearing. The measuring device has the capability of rapidly and precisely measuring the equivalent friction torque and equivalent friction coefficientof the rolling bearing.

Owner:TIANJIN UNIV

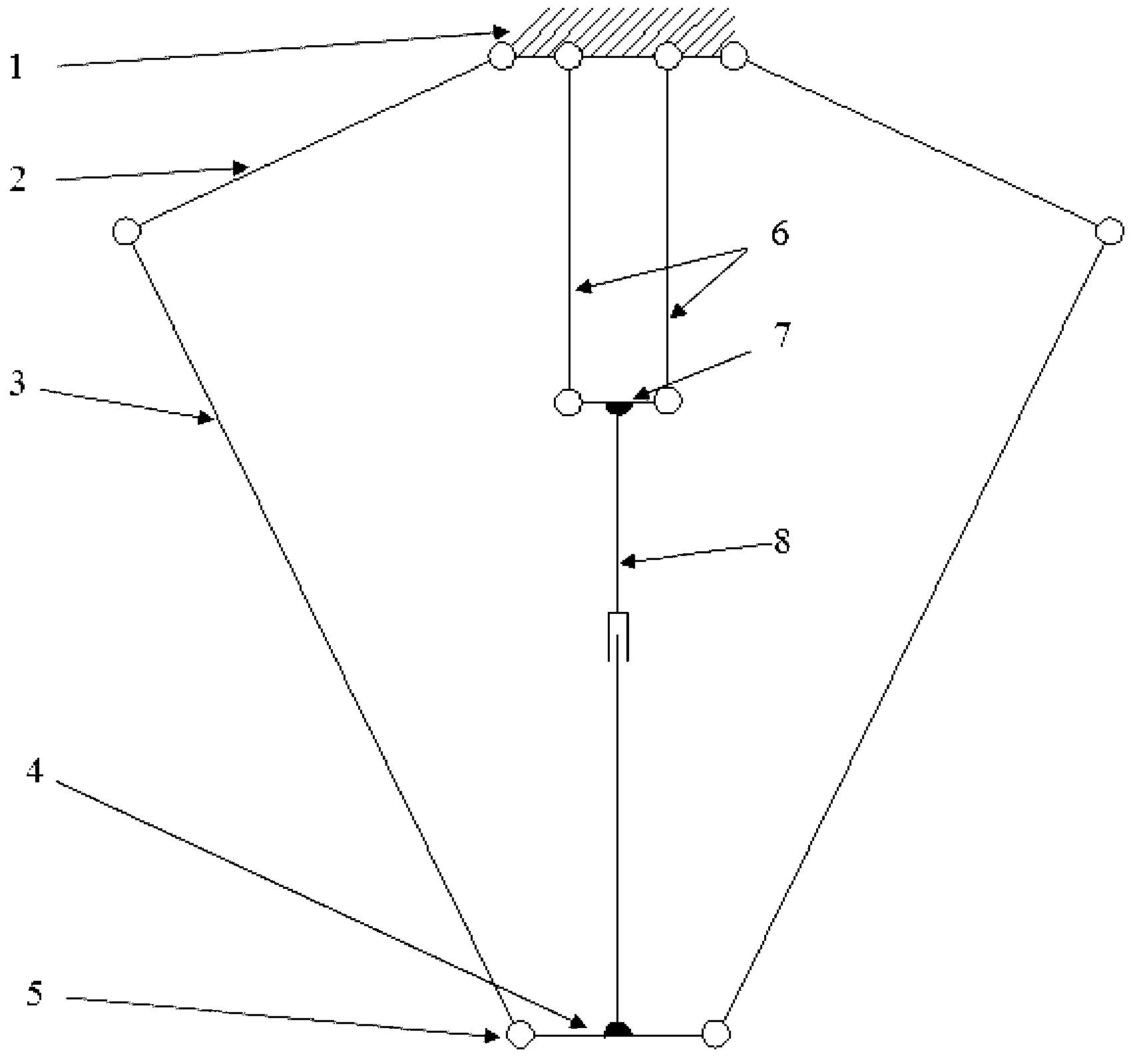

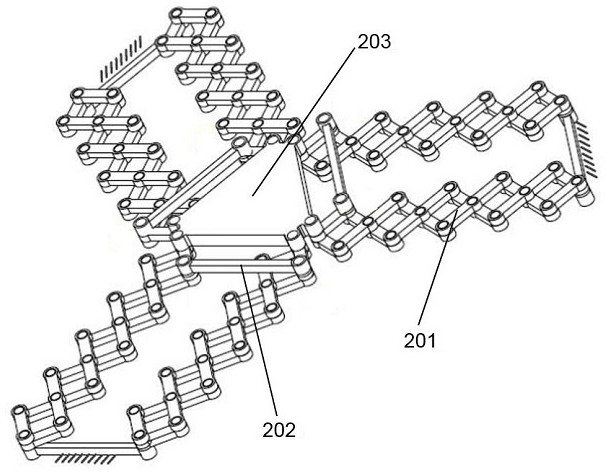

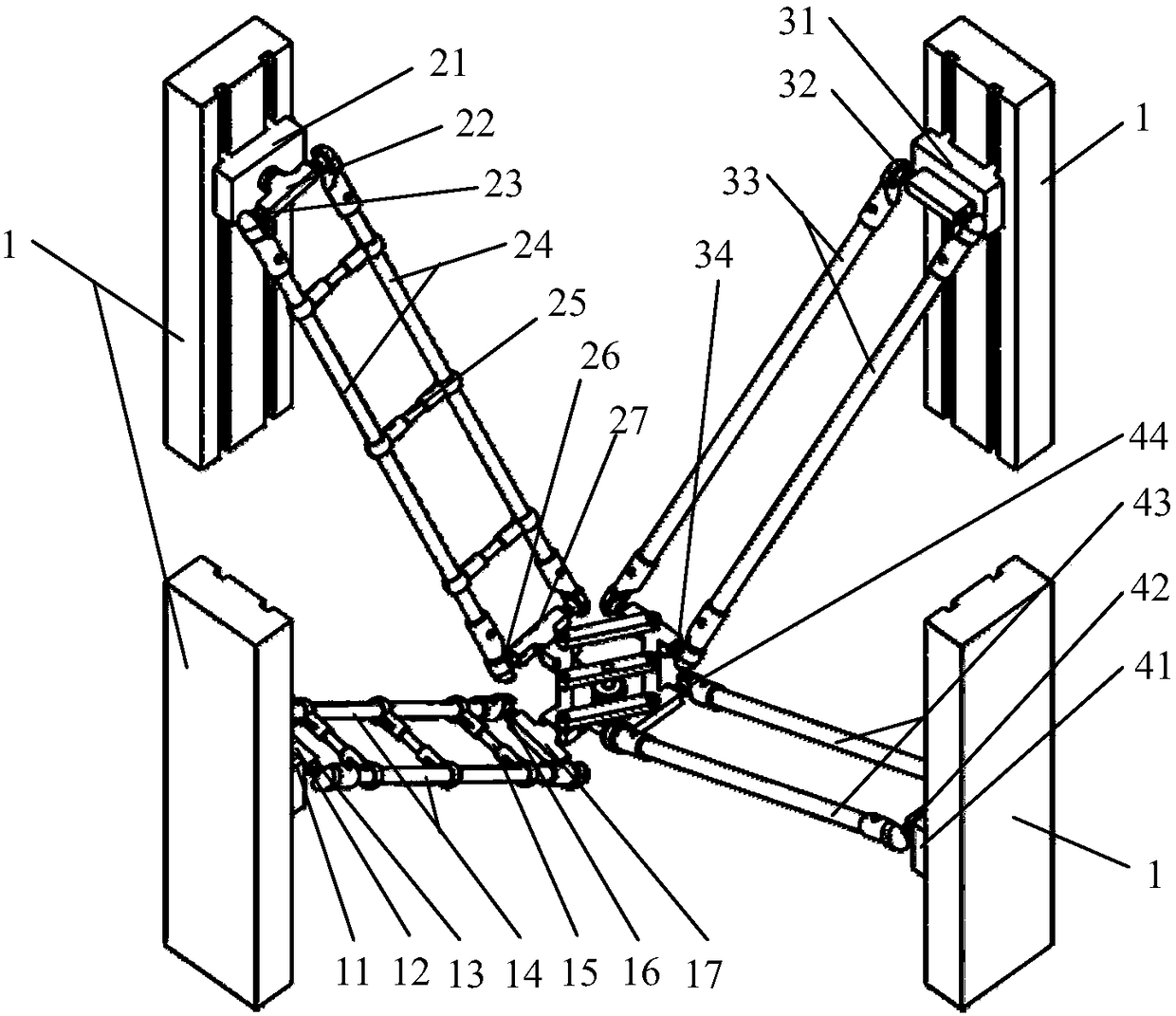

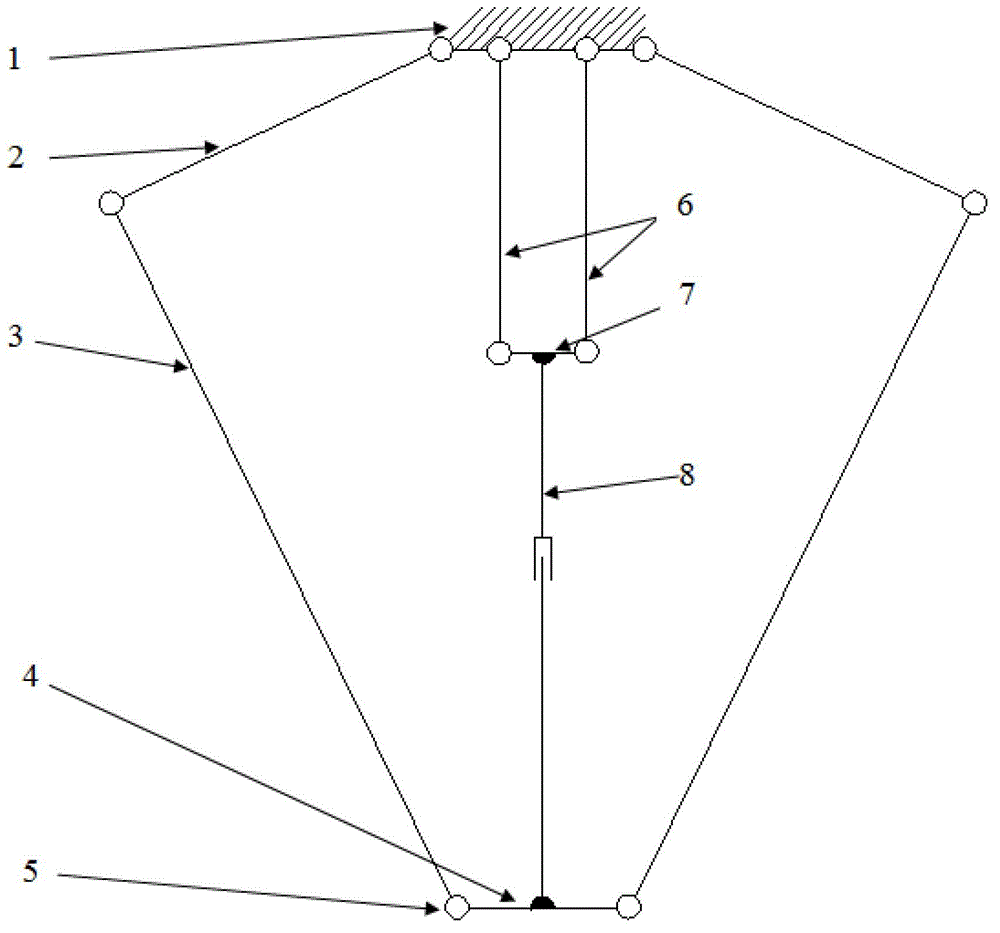

Parallel mechanism achieving three-dimensional translation, one-dimensional rotation and four degrees of freedom

InactiveCN108656079ACompact structureThe movement method is clearProgramme-controlled manipulatorMoving partsKinematics

The invention relates to a parallel mechanism achieving three-dimensional translation, one-dimensional rotation and four degrees of freedom. The parallel mechanism comprises a stationary platform, a movable platform, a first driving branch chain, a second driving branch chain, a third driving branch chain and a fourth driving branch chain, wherein the first driving branch chain, the second drivingbranch chain, the third driving branch chain and the fourth driving branch chain are connected with the two platforms. Every two adjacent driving branch chains are distributed in a 90-degree spatialsymmetry mode, and each driving branch chain is a parallelogram-shaped connecting rod and sliding block mechanism. The parallel mechanism has the advantages of being simple and compact in structure and specific in mode of movement. The four driving branch chains have the same mechanical structures, the kinematic performance and the dynamic performance also have the symmetry, the movement capacities of the driving branch chains are limited with each other, and the three-dimensional translational movement with the high space velocity and the one-dimensional rotational movement with the large rotational range can be achieved. In addition, the movable platform of the parallel mechanism adopts the structural style of a single platform, the mass of moving parts can be reduced, and the high-speedand high-acceleration dynamic response characteristic can be achieved advantageously.

Owner:SHANGHAI UNIV

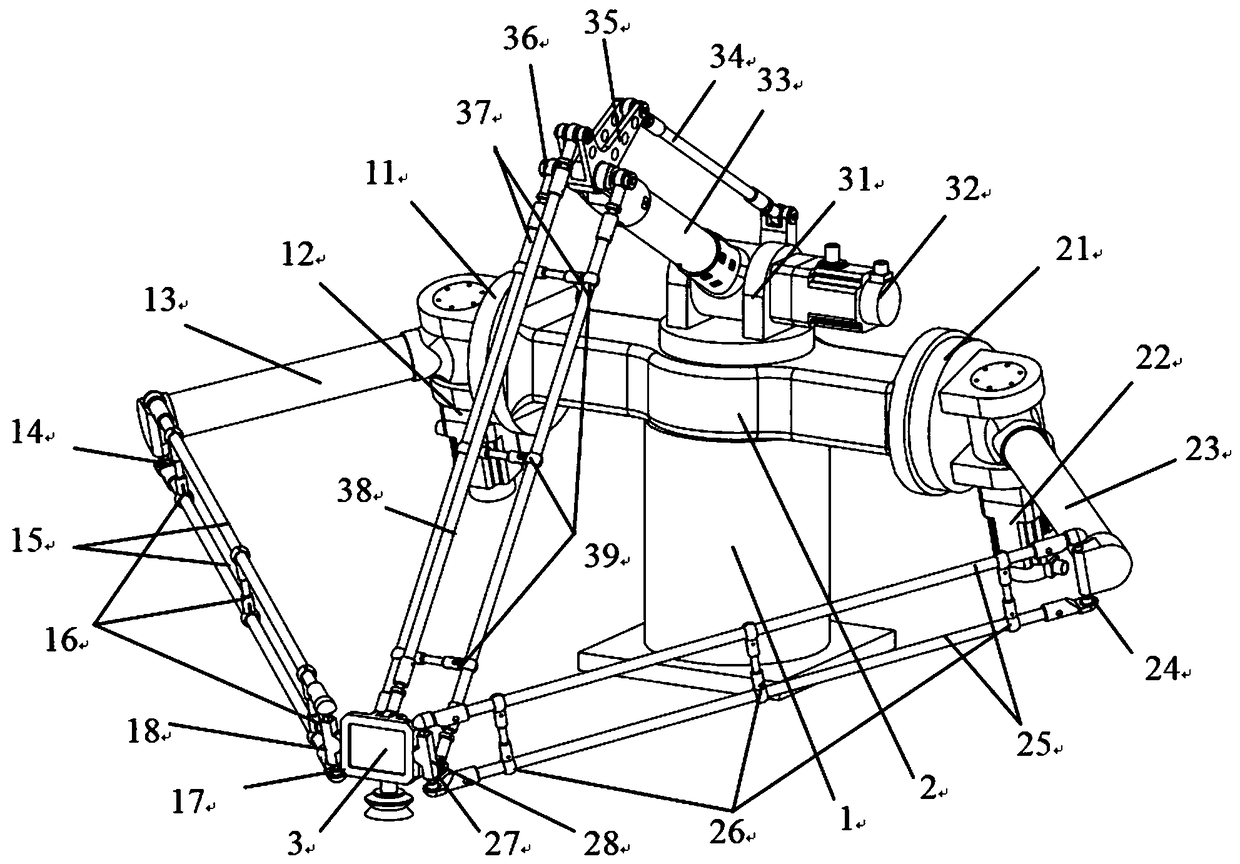

A docking mechanism suitable for water sample collection

ActiveCN108760397BCompact structureThe movement method is clearWithdrawing sample devicesClassical mechanicsEngineering

The invention relates to an abutting joint mechanism suitable for water sample collection. The abutting joint mechanism includes an upper part and a lower part. The upper part is a passive abutting joint structure, and includes a linear pushing bar, a two-degree-freedom plane translation unit, a bellows coupler and an upper abutting joint. The upper abutting joint is connected to the two-degree-freedom plane translation unit through the bellows coupler, achieving translation movement of the upper abutting joint in the horizontal plane. The linear pushing bar achieves translation movement of the upper abutting joint in the vertical direction. The lower part is a water sample collection unit and includes a layered water sampler and a lower abutting joint. The lower abutting joint is fixed tothe top of the layered water sampler, and is provided with a pipeline inside used for extracting a water sample in the layered water sampler. The disclosed abutting joint mechanism has characteristics of a simple and compact structure and definite movement manners, can achieve three-dimensional translation movement in a high movement speed and a large movement range, thus achieving rapid and accurate abutting. The abutting joint mechanism is suitable for automatic water sample collection in unmanned surface boats.

Owner:SHANGHAI UNIV

Four degrees of freedom parallel mechanism

ActiveCN105522559BClear division of laborSimple structureProgramme-controlled manipulatorStructural engineeringBevel gear

The invention relates to the technical field of automobile parts, in particular to a four-degree-of-freedom parallel mechanism. The four-degree-of-freedom parallel mechanism comprises a fixed frame, a movable platform and four branch chains. The branch chains are symmetrically arranged between the fixed frame and the movable platform and of the same structure. The movable platform is mainly composed of a main platform and a vice platform. The vice platform is connected with the main platform in a sleeving mode through a bevel gear pair. The axis of a big bevel gear of the bevel gear pair and the axis center of the main platform are coaxial, and the big bevel gear is fixed to one side of the vice platform. A small bevel gear of the bevel gear pair is installed on the main platform. The axis of the big bevel gear is perpendicular to the axis of the small bevel gear. An end effector is installed on the lower portion of the small bevel gear. The four-degree-of-freedom parallel mechanism is simple in structure and clear in motion mode. A large rotation angle range is obtained due to the large transmission ratio of the bevel gear pair, so that a magnification mechanism does not need to be used, and the motion speed is greatly increased.

Owner:CHENXING (TIANJIN) AUTOMATION EQUIP CO LTD

A high-speed parallel robot mechanism capable of scara motion

ActiveCN106584426BCompact structureThe movement method is clearProgramme-controlled manipulatorFixed frameSpherical joint

The invention discloses a high-speed parallel robot mechanism capable of realizing SCARA motion. The high-speed parallel robot mechanism comprises fixed brackets, a mobile platform as well as a first support chain, a second support chain, a third support chain and a fourth support chain which are arranged between the mobile platform and the fixed brackets, wherein each of the first support chain and the second support chain comprises a slide plate, a rotating shaft A, two parallel far frame rods with equal length and a rotating shaft B, the slide plate is connected with the fixed brackets through a slide pair, the rotating shaft A is rotationally connected with the slide plate, one end of each far frame rod is in spherical joint with the rotating shaft A, the other end is in spherical joint with the rotating shaft B, and the rotating shaft B is rotationally connected with the mobile platform; and each of the third support chain and the fourth support chain comprises a slide plate and two parallel far frame rods with equal length, the slide plate is connected with the fixed frame through a slide pair, one end of each far frame rod is in spherical joint with the slide plate, and the other end is in spherical joint with the mobile platform. The high-speed parallel robot mechanism is skillful in design, compact in structure and can adapt to complicated gripping and releasing environments.

Owner:江苏小野智能装备有限公司

Device and method for measuring equivalent friction coefficient of vertical rolling bearing

ActiveCN109238707BHigh measurement/calculation accuracyAccurate measurement accuracyMachine bearings testingFriction torqueRolling-element bearing

The invention discloses a vertical rolling bearing equivalent friction coefficient measuring device. The vertical rolling bearing equivalent friction coefficient measuring device comprises a machine body, a sliding table, a mandrel, two bearing pedestals, a rotating speed sensor and a data acquisition / processing / calculation / display device, wherein one of the bearing pedestals is fixedly connectedwith the machine body, and the other one is fixedly connected with the sliding table; an A to-be-tested rolling bearing outer ring is arranged on a bearing pedestal shoulder which is fixedly connectedwith the machine body, and a B to-be-tested rolling bearing outer ring is arranged on a bearing pedestal shoulder which is fixedly connected with the sliding table; an A to-be-tested rolling bearinginner ring is arranged on the shaft shoulder at one end of the mandrel, and a B to-be-tested rolling bearing inner ring is arranged on the shaft shoulder at the other end of the mandrel; the sliding table is capable of horizontally moving along the axial direction of the inner cylindrical surface of the bearing pedestals under the guide of a guide component; and the data acquisition / processing / calculation / display device is used for collecting and processing the angular speed signal, monitored by the rotating speed sensor, of the mandrel, and calculating the equivalent friction torque and equivalent friction coefficient of the tested rolling bearing. The measuring device has the capability of rapidly and precisely measuring the equivalent friction torque and equivalent friction coefficientof the rolling bearing.

Owner:TIANJIN UNIV

A four-degree-of-freedom high-speed parallel robot mechanism

ActiveCN106313004BCompact structureThe movement method is clearProgramme-controlled manipulatorRotational axisFixed frame

The invention discloses a four-freedom-degree high-speed parallel robot mechanism which comprises a fixed frame, a moving platform, a first branched chain, a second branched chain, a third branched chain and a fourth branched chain. The first branched chain, the second branched chain, the third branched chain and the fourth branched chain are arranged between the fixed frame and the moving platform. The first branched chain and the second branched chain each comprise a rotating fork, a close frame bar, two parallel and equilong far frame bars and a rotating shaft, wherein each rotating fork is rotationally connected with the fixed frame, one end of each close frame bar is rotationally connected with the corresponding rotating fork, the other end of each close frame bar is spherically hinged to the corresponding far frame bars, each far frame bar is spherically hinged to the corresponding rotating shaft, and each rotating shaft is rotationally connected with the moving platform. The third branched chain and the fourth branched chain each comprise a close frame bar and two parallel and equilong far frame bars, wherein one end of each close frame bar is rotationally connected with the fixed frame, the other end of each close frame bar is spherically hinged to the corresponding far frame bars, and each far frame bar is spherically hinged to the moving platform. The mechanism is ingenious in design and compact in structure and can adapt to complex grabbing and releasing environments.

Owner:NANJING UNIV OF SCI & TECH

A Parallel Mechanism with Two Degrees of Freedom Translation

ActiveCN103273481BLow machining accuracy requirementsHigh positioning accuracyProgramme-controlled manipulatorDegrees of freedomMechanical engineering

The invention discloses a parallel mechanism with a two-degree-of-free translation function. The parallel mechanism comprises a fixed frame, a movable platform, two driving branched chains identical in structure and a driven branched chain, the two driving branched chains are symmetrically arranged between the fixed frame and the movable platform and on two sides of the driven branched chain, the driven branched chain comprises two rod members in left-right parallelism, the upper ends of the rod members are connected with the fixed frame through a rotating pair while the lower ends of the same are connected with the end portion of a horizontal connecting rod, the fixed frame, the two rod members and the horizontal connecting rod form a parallelogram structure, a vertical connecting rod perpendicular to the horizontal connecting rod is fixedly connected below the middle portion of the horizontal connecting rod, and the movable platform comprises a transverse rod and a vertical rod which is vertically fixed above the middle portion of the transverse rod and connected with the vertical connecting rod through a moving pair. The parallel mechanism is low in manufacturing cost, smoother in operating and higher in motion transmitting efficiency.

Owner:江苏小野智能装备有限公司

A three-degree-of-freedom robot mechanism capable of realizing two levels and one rotation

ActiveCN106272361BCompact structureThe movement method is clearProgramme-controlled manipulatorThree degrees of freedomEngineering

The invention discloses a three-freedom-degree robot mechanism capable of translating in two directions and rotating in one direction. The three-freedom-degree robot mechanism capable of translating in two directions and rotating in one direction comprises a fixed frame, a moving platform, and a first branched chain, a second branched chain and a third branched chain which are arranged between the fixed frame and the moving platform; each of the three branched chains comprises a near frame rod and two parallel far frame rods with equal lengths; the third branched chain also comprises a converting fork; the converting fork is fixedly connected with the fixed frame; one end of the near frame rod is connected with the fixed frame or the converting fork; the other end of the near frame rod is spherically hinged to the far frame rod; the far frame rod is spherically hinged to the moving platform; the moving platform comprises a primary platform and a secondary platform which can rotate relatively; the mechanism is high in rigidity, flexible in movement, and can realize high-speed grasping and releasing.

Owner:NANJING UNIV OF SCI & TECH

A Parallel Robot Mechanism Realizing Scara Motion

ActiveCN106584427BThe movement method is clearIncrease stiffnessProgramme-controlled manipulatorEngineeringSCARA

The invention discloses a parallel robot mechanism capable of achieving SCARA motion. The parallel robot mechanism comprises a fixing frame, a movable platform, a first branched chain, a second branched chain, a third branched chain and a fourth branched chain, wherein the first branched chain, the second branched chain, the third branched chain and the fourth branched chain are arranged between the fixing frame and the movable platform; the four branched chain each comprise a near frame rod and two parallel and equal-length far frame rods, one end of each near frame rod is rotationally connected with the fixing frame, and the other end of each near frame rod is in ball hinge to the corresponding far frame rods; the far frame rods are in ball hinge to the movable platform; and the movable platform comprises a main platform, an auxiliary platform and two rotating shafts, and the auxiliary platform and the two rotating shafts are rotationally connected with the main platform. The mechanism is ingenious in design, compact in structure and capable of adapting to complex grabbing and placing environments.

Owner:江苏小野智能装备有限公司

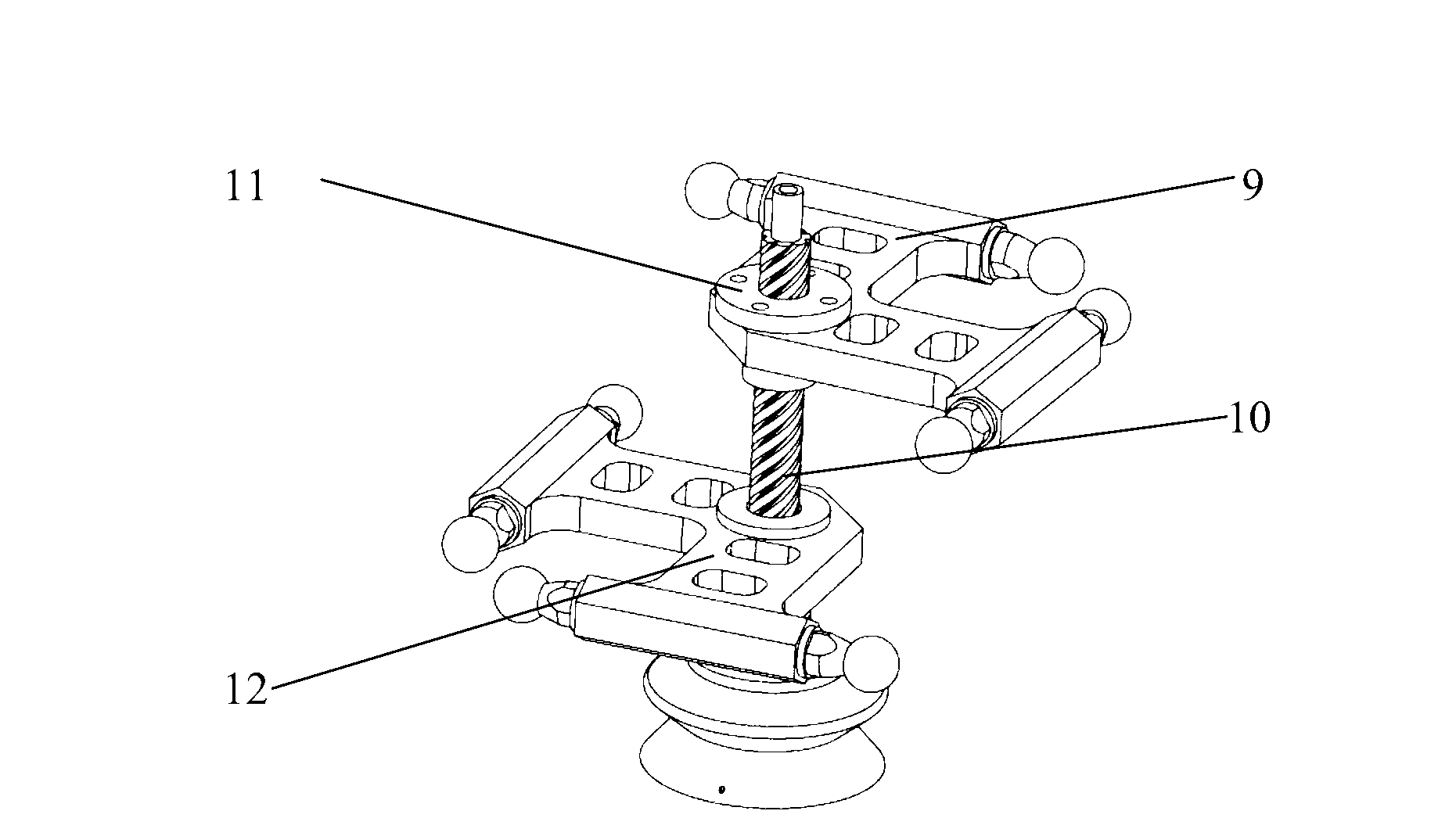

Up-and-down telescopic three-platform one-rotation parallel mechanism

ActiveCN102161201BSmall sizeGuaranteed uptimeProgramme-controlled manipulatorFixed frameMarine engineering

The invention discloses an up-and-down telescopic three-platform one-rotation parallel mechanism, comprising a fixed frame, a moving platform and four groups of branch chains, wherein the branch chains are same in structure and are symmetrically arranged between the fixed frame and the moving platform; the moving platform comprises an upper platform and a lower platform which are mutually parallel; the vertical axes of the upper platform and the lower platform are coincident; a connecting rod group guiding mechanism is connected between the upper platform and the lower platform, and consists of at least three dual-connecting-rod structures which are same in structure and are distributed along the circumference of the vertical axis of the moving platform; each dual-connecting-rod structurecomprises an upper connecting rod hinged with the upper platform and a lower connecting rod hinged with the lower platform; and the upper connecting rod is hinged with the lower connecting rod. In the up-and-down telescopic three-platform one-rotation parallel mechanism, relative movement of the upper platform and the lower platform along the direction of the common vertical axis is converted into the rotation of a lead screw around the axis of the lead screw through a rotating mechanism and the connecting rod group guiding mechanism, the vertical relative movement of the upper platform and the lower platform is guaranteed by utilizing the constrained characteristic of the connecting rod group guiding mechanism, and the rigidity and the stability are good.

Owner:WUHU IROBSYS ROBOT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com