Four-degree-of-freedom parallel mechanism

A degree of freedom and parallel technology, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of reduced speed of mechanism operation, difficulties in positive and negative solutions, and increased costs, so as to achieve increased speed, high feasibility and controllability The effect of sex and complexity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

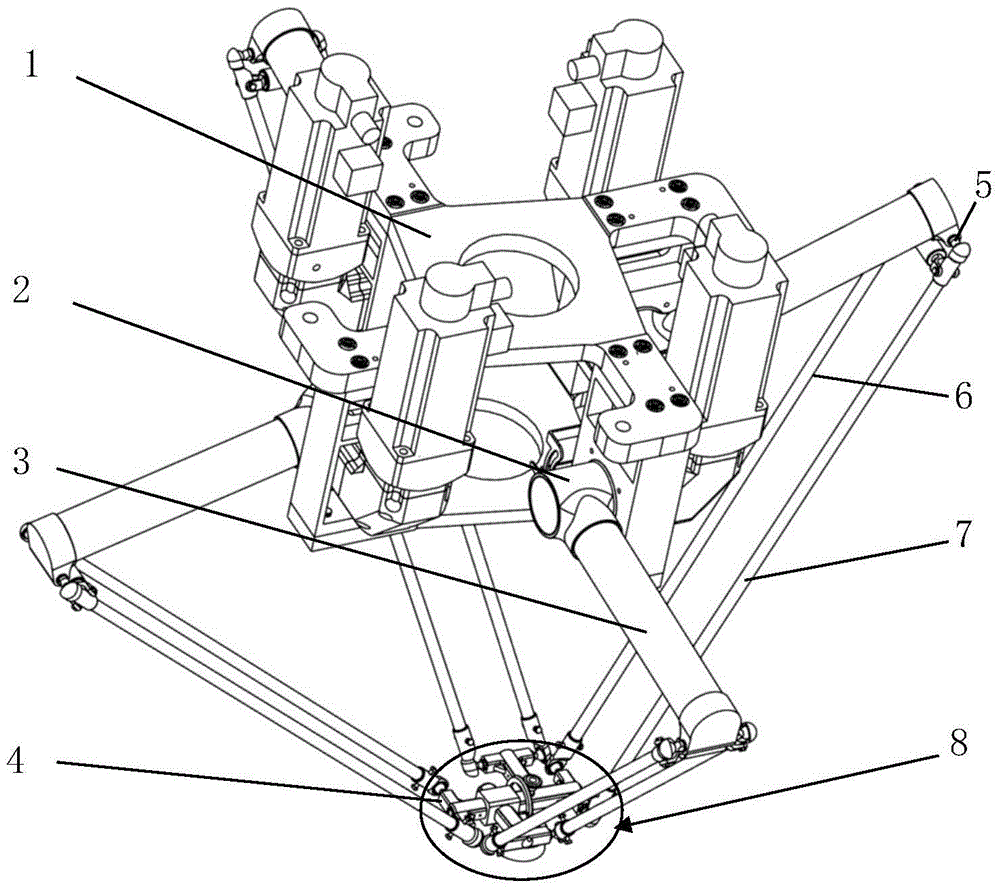

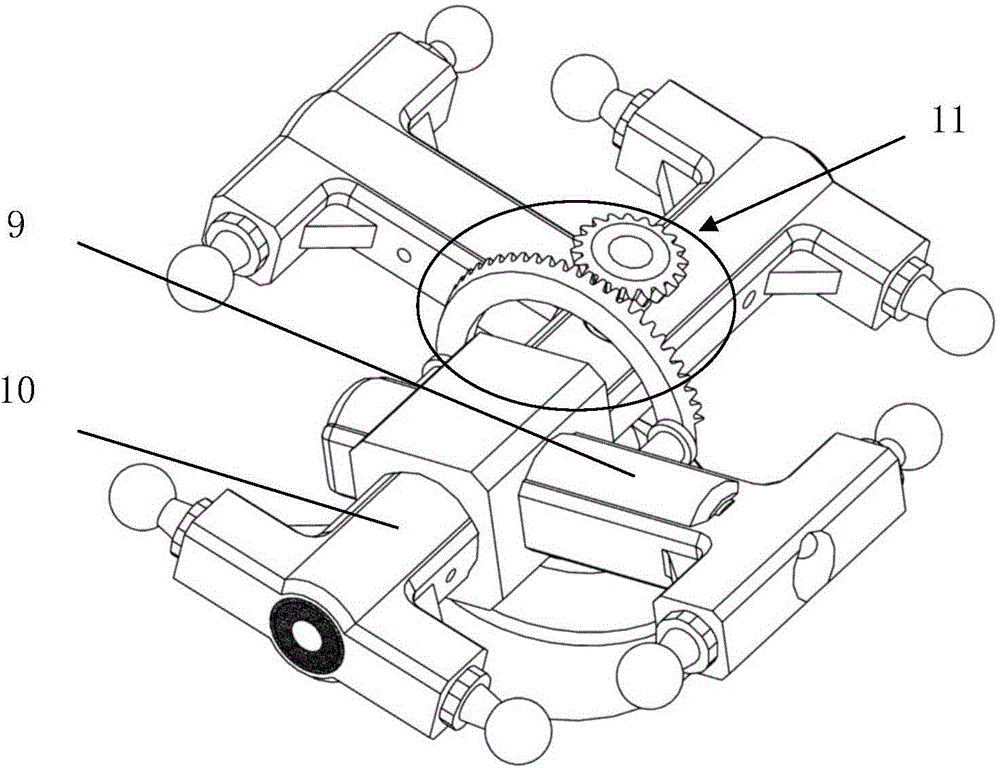

[0012] The specific implementation manner of the present invention will be described in detail below in conjunction with accompanying drawing and preferred embodiment, as figure 1 shown, refer to figure 1 , the present invention is a four-degree-of-freedom parallel mechanism with three-dimensional translation and one-dimensional rotation, including a fixed frame 1, a moving platform 8, and four branch chains with the same structure symmetrically arranged between the fixed frame 1 and the moving platform 8 Constituent; each branch chain is made up of nearly frame bar 3, far frame bar 6 and 7 and the upper connecting shaft 5 that connects described near frame bar 3 and far frame bar 6 and 7. One end of the near frame rod 3 is affixed to the drive shaft 2 of the fixed frame 1, and its other end is affixed to the upper connecting shaft 5; the far frame rods 6 and 7 are arranged in parallel, and one end thereof is respectively connected to the The upper connecting shaft 3 is ball-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com