Parallel mechanism with three-dimensional translation and one-dimensional rotation functions

A three-dimensional translation and parallel technology, applied in the field of robotics, can solve the problems of increasing the weight of the moving platform, which is not conducive to improving the efficiency of the mechanism, and achieve the effect of reducing quality and complexity, simple structure, and clear movement mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

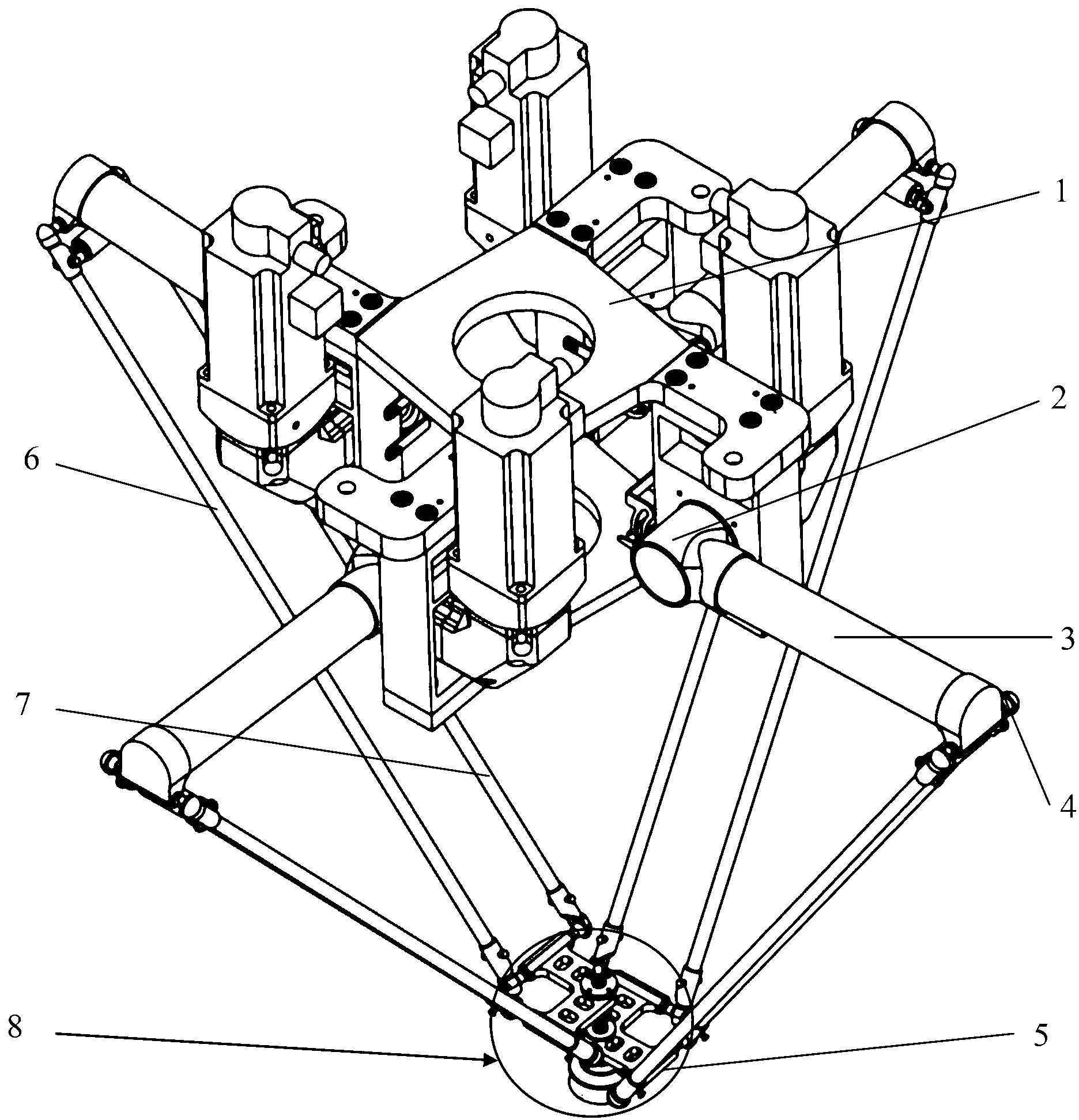

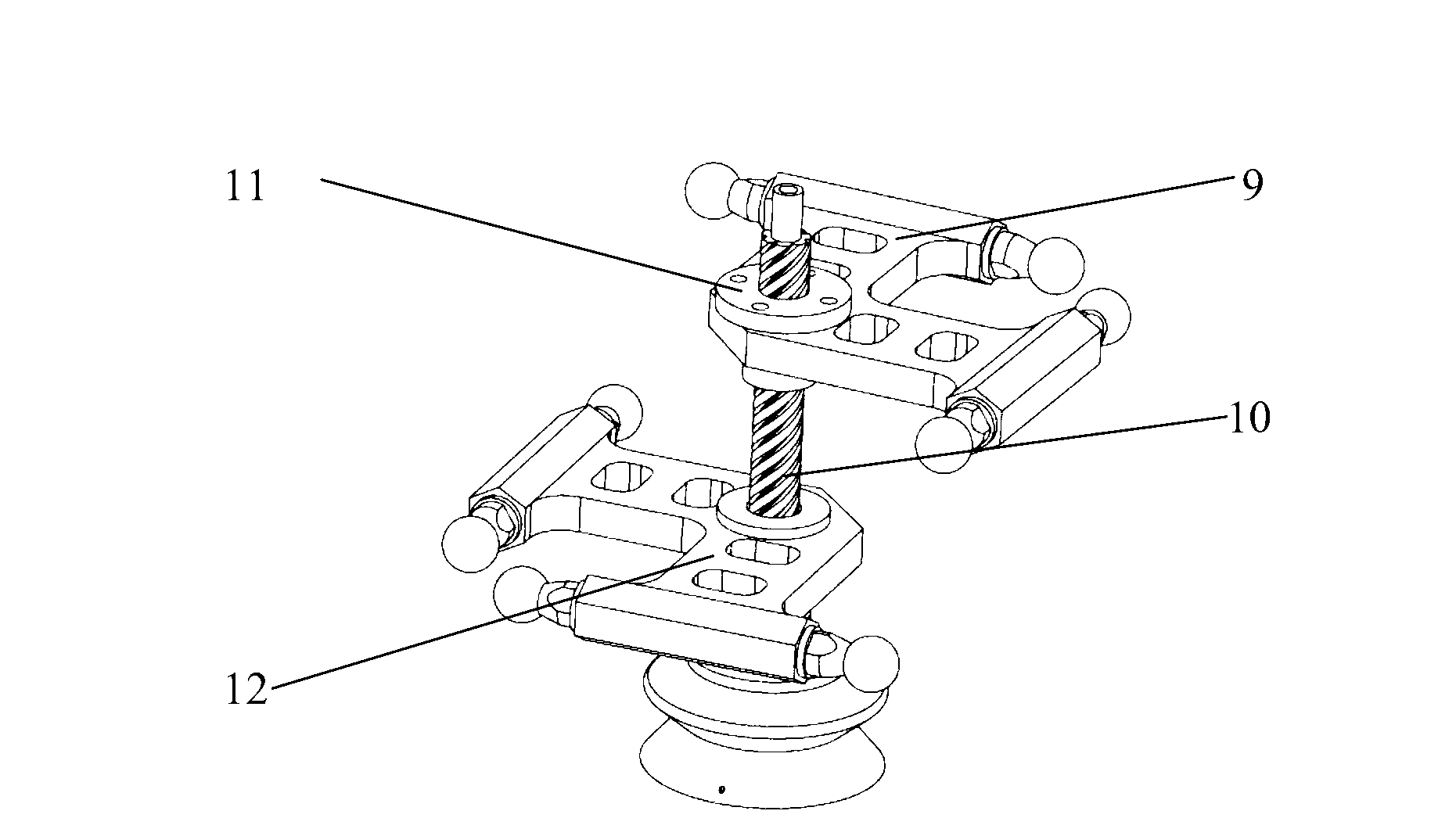

[0016] see Figure 1 ~ Figure 2 , a parallel mechanism with three-dimensional translation and one-dimensional rotation, including a fixed frame 1, a moving platform 8, and four branch chains with the same structure symmetrically arranged between the fixed frame 1 and the moving platform 8.

[0017] Each branch chain comprises nearly frame bar 3, two parallel far frame bars 6,7 and the upper connecting shaft 4 and the lower connecting shaft 5 of far frame bar 6,7, and the lower connecting shaft 5, upper connecting shaft on every branch chain The connecting shaft 4 and the two parallel remote frame rods 6, 7 form a parallelogram. One end of the near frame rod 3 is affixed to the rotary drive device installed on the fixed frame, and its other e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com