Four-degree-of-freedom parallel mechanism capable of realizing three-dimensional translation and one-dimensional rotation

A degree of freedom, parallel technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of heavy moving platform weight, complex moving platform structure, unfavorable mechanism dynamic response characteristics, etc., to achieve simple and compact structure and improve dynamic response. Features, Effects of Mass Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

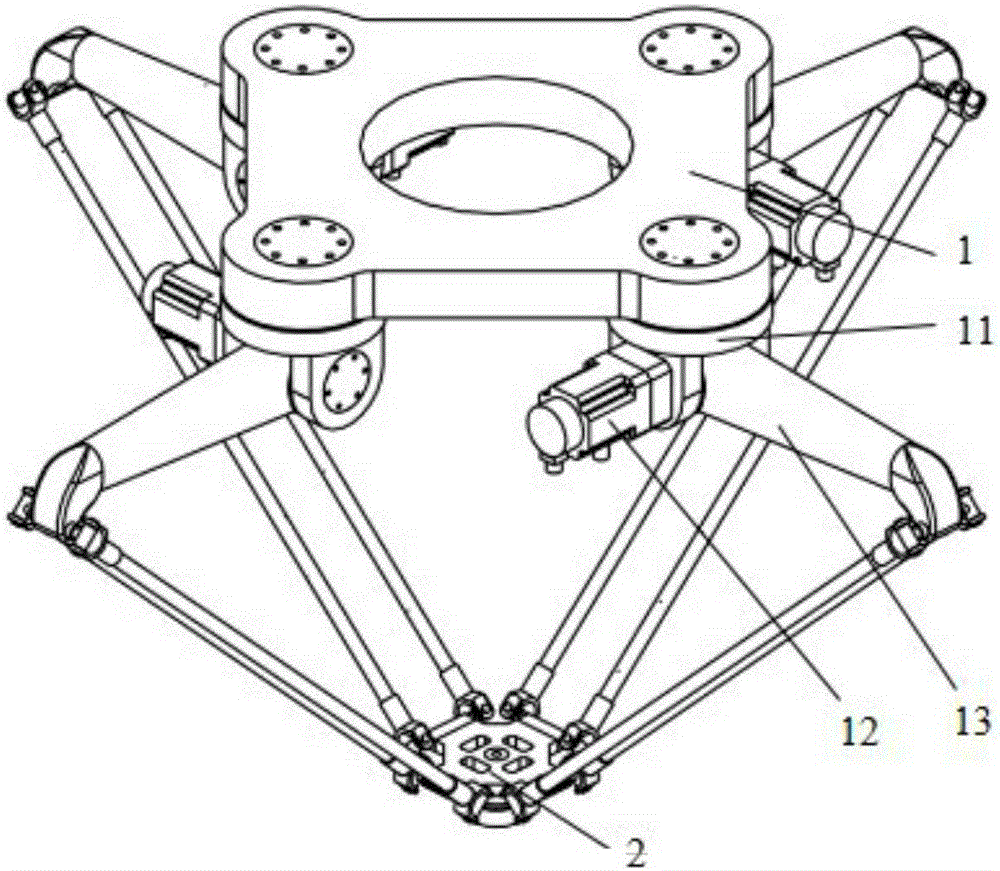

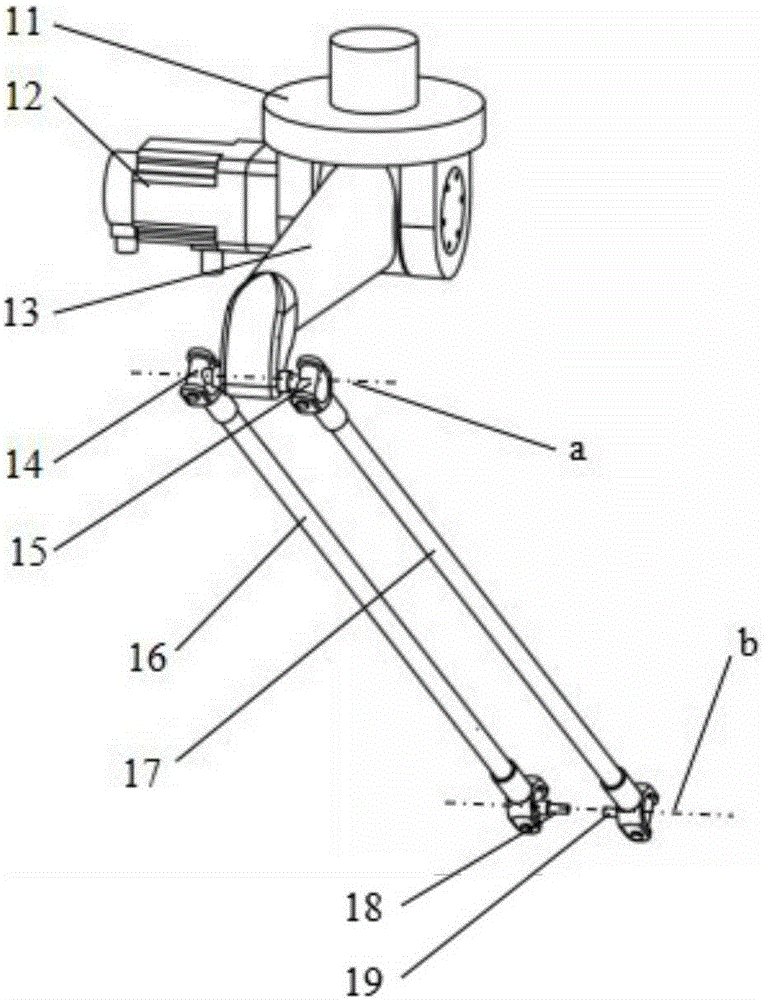

[0037] to combine Figure 1~4, a three-level one-rotation four-degree-of-freedom parallel mechanism, including a fixed frame 1, a moving platform 2, and a first branch chain, a second branch chain, a third branch chain and a fourth branch chain arranged between the fixed frame and the moving platform. Branched chains, the first branched chain, the second branched chain, the third branched chain and the fourth branched chain have the same structure; each branched chain includes a rotating fork 11, a driving device 12 fixedly arranged on the rotating fork 11, a driving Arm 13, first T-shaped shaft 14, second T-shaped shaft 15, first driven arm 16, second driven arm 17, third T-shaped shaft 18 and fourth T-shaped shaft 19; Rotationally connected on the fixed frame 1, one end of the active arm 13 is rotatably connected in the rotating fork 11, and is fixedly connected with the driving end of the driving device 12, and the two ends of the end of the active arm 13 away from the driv...

Embodiment 2

[0043] combine Figure 5 , on the basis of embodiment 1, the driving device 12 of one of the branch chains in the four branch chains is fixedly connected with the fixed frame 1, and its driving end is fixedly connected with the rotating fork 11, so that the rotating fork 11 and The revolving pair between the fixed frame 1 is the active revolving pair. At this time, there is no restriction on the shape of the moving platform 2, that is, the quadrilateral formed by the hinge midpoint 3 connecting the four branch chains with the moving platform 2 may be non-square or square.

Embodiment 3

[0045] combine Figure 6~8 , a three-level one-rotation four-degree-of-freedom parallel mechanism, including a fixed frame 1, a moving platform 2, and a first branch chain, a second branch chain, a third branch chain and a fourth branch chain arranged between the fixed frame and the moving platform. Branched chains, the first branched chain, the second branched chain, the third branched chain and the fourth branched chain have the same structure; each branched chain includes a rotating fork 11, a driving device 12 fixedly arranged on the rotating fork, a driving arm 13. The first ball joint 141 , the second ball joint 151 , the first follower arm 16 , the second follower arm 17 , the third ball joint 181 and the fourth ball joint 191 . The rotating fork 11 is rotatably connected to the fixed frame 2, and one end of the active arm 13 is rotatably connected in the rotating fork 11, and is fixedly connected to the driving end of the driving device 12, and the active arm 13 is far...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com