A Parallel Robot Mechanism Realizing Scara Motion

A robot and parallel technology, applied in manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of unfavorable mechanism dynamic response characteristics, easy to generate vibration, etc., to improve stiffness and dynamic response characteristics, simple and compact mechanism, and realize high-speed and The effect of high acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

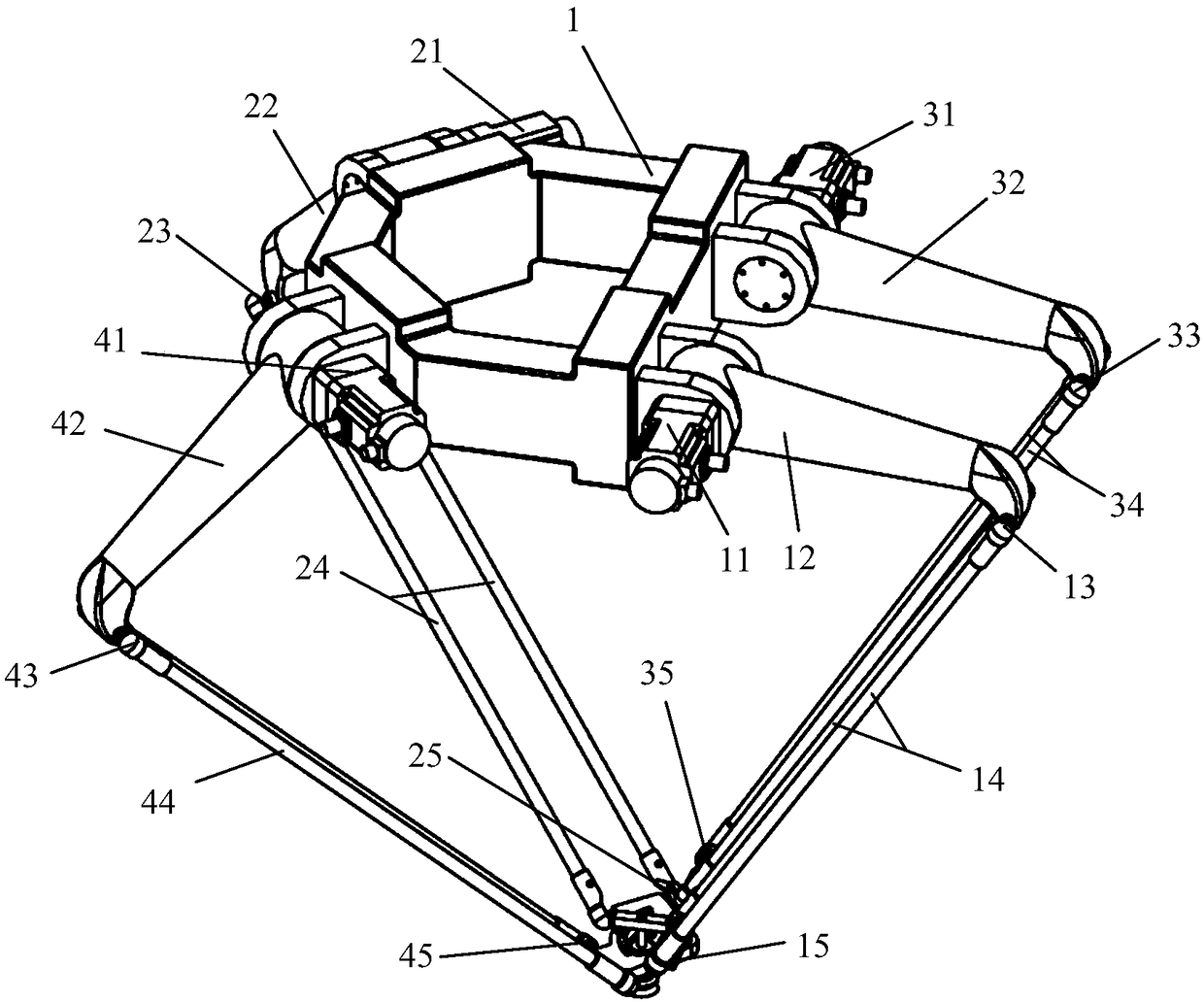

[0037] combined with Figure 1-2 , a parallel robot mechanism that can realize SCARA motion, including a fixed frame 1, a moving platform, and a first branch chain, a second branch chain, a third branch chain and a fourth branch chain arranged between the fixed frame 1 and the moving platform , taking the first branch chain as an example, the four branch chains all include a driving device 11, a near frame rod 12, an upper connecting shaft 13, a lower connecting shaft 15, two parallel and equal long far frame rods 14, and the driving The device 11 is fixedly connected with the fixed frame 1, and one end of the near frame rod 12 is rotationally connected with the fixed frame 1, and is fixedly connected with the driving end of the driving device 11, and the other end is fixedly connected with an upper connecting shaft 13, and the far frame rod One end of 14 is ball-hinged with upper connecting shaft 13, and the other end of said remote frame rod 14 is ball-hinged with lower conn...

Embodiment 2

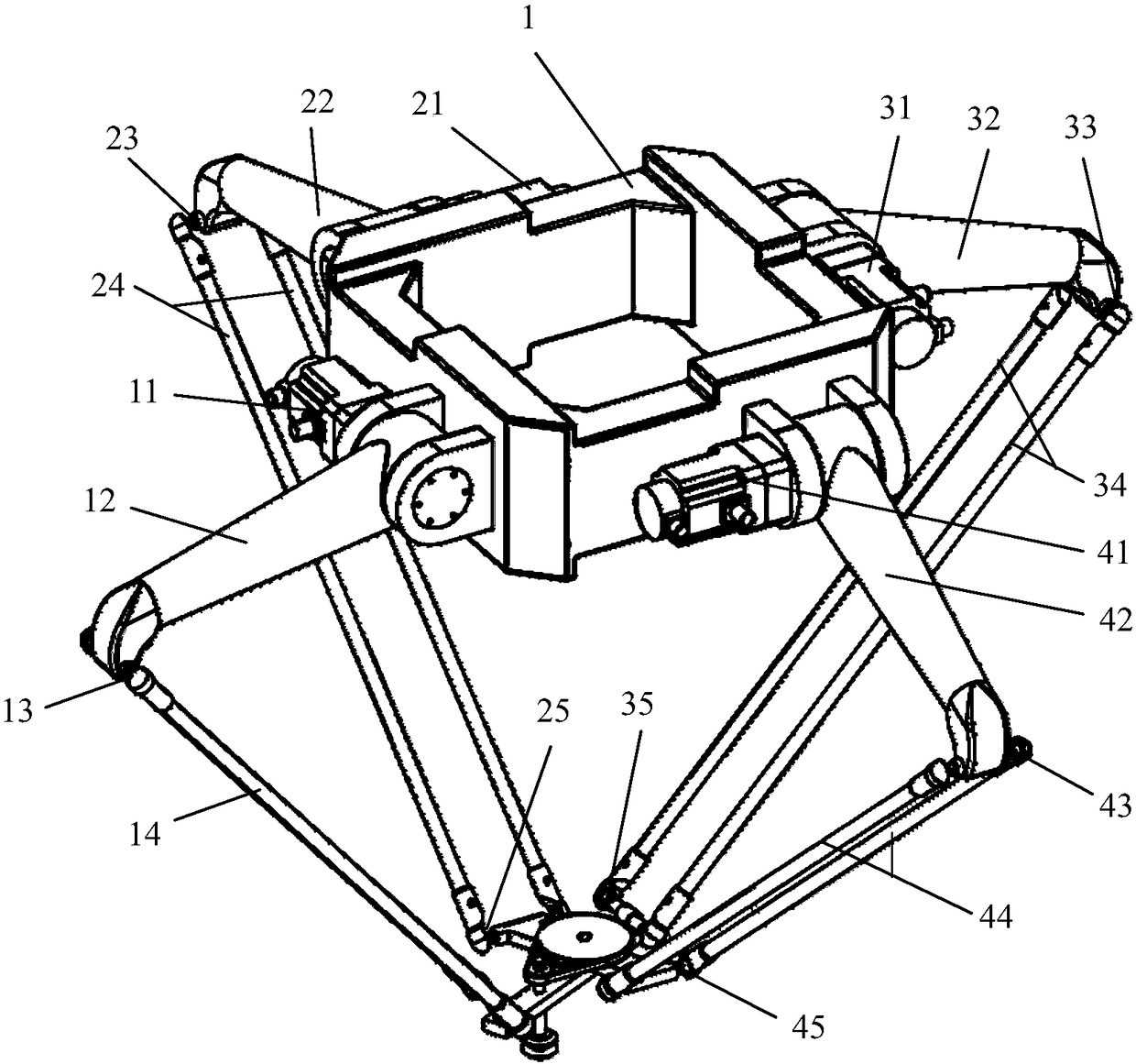

[0044] combined with Figure 3-4 , this embodiment is similar to embodiment 1, the difference is only in:

[0045] The first branch chain and the third branch chain are oppositely arranged.

[0046] A large pulley 103 is fixedly connected to the auxiliary platform 5; a small pulley 101 is connected to the main platform 2; the small pulley 101 and the large pulley 103 are connected by a belt 102; the small belt The end effector 10 is fixedly connected to the lower end of the wheel 101 . The central axis of the large pulley 103 is coaxial with the rotation axis connecting the main platform 2 and the auxiliary platform 5 .

Embodiment 3

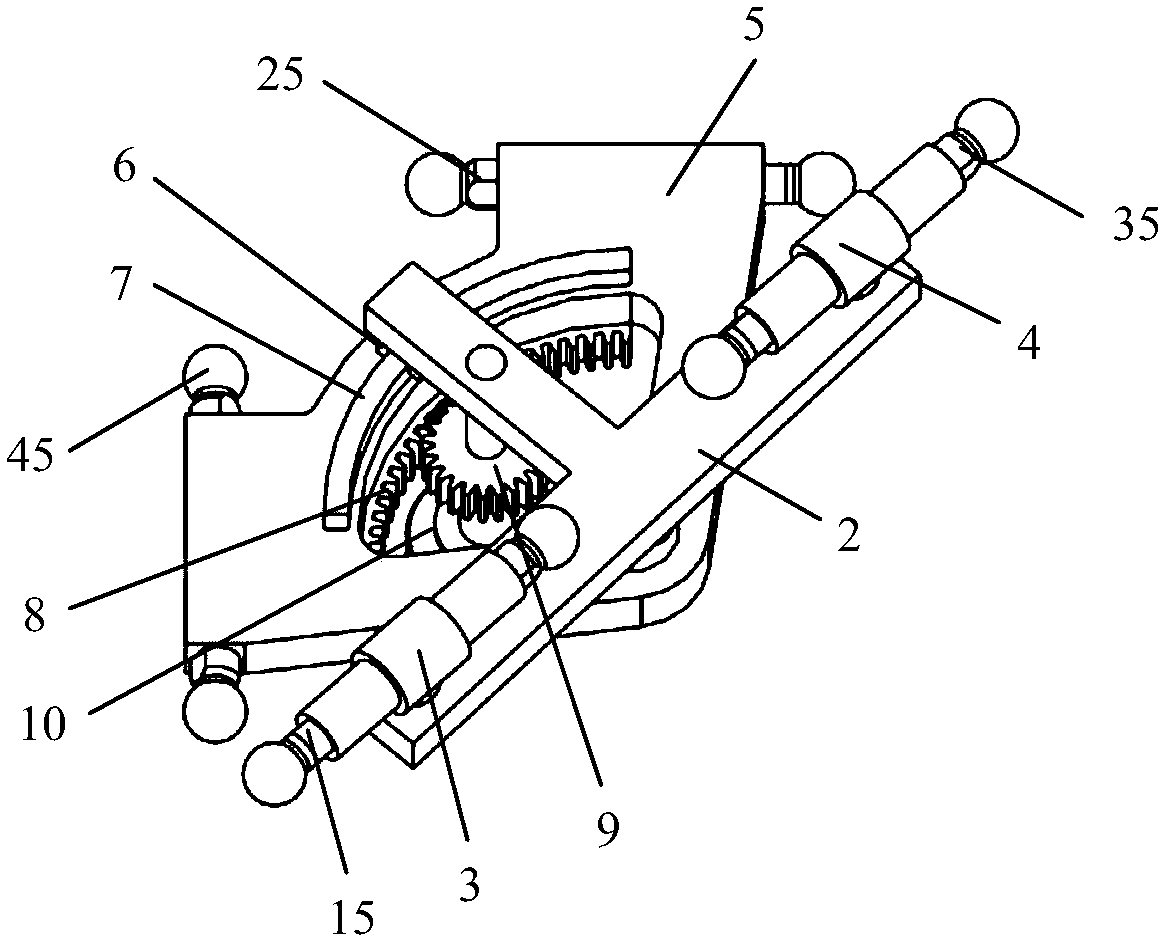

[0048] combined with Figure 5-6 , this embodiment is similar to embodiment 2, the only difference is:

[0049] A large toothed fan 104 is fixedly connected to the auxiliary platform 5; a pinion 9 is connected to the main platform 2; the small gear 9 meshes with the large toothed fan 104; an end effector is fixedly connected to the lower end of the small gear . The central axis of the large tooth sector 104 is coaxial with the rotation axis connecting the main platform 2 and the auxiliary platform 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com