Sheet-fed offset printing press for printing on both sides of sheets

A sheet-fed, offset press technology, used in printing presses, rotary presses, offset rotary presses, etc., to solve problems such as high wear and tear of machine parts and adverse effects on printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

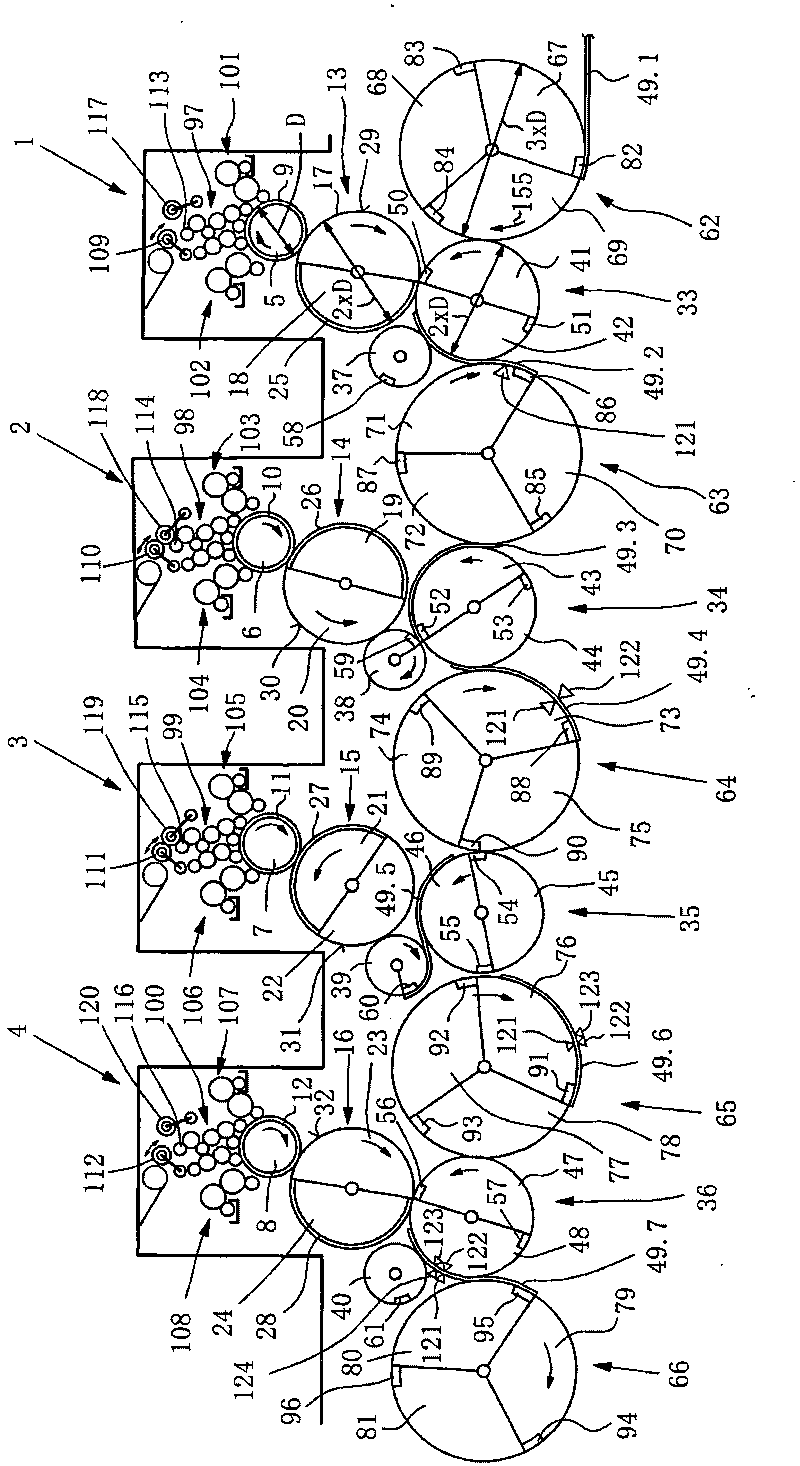

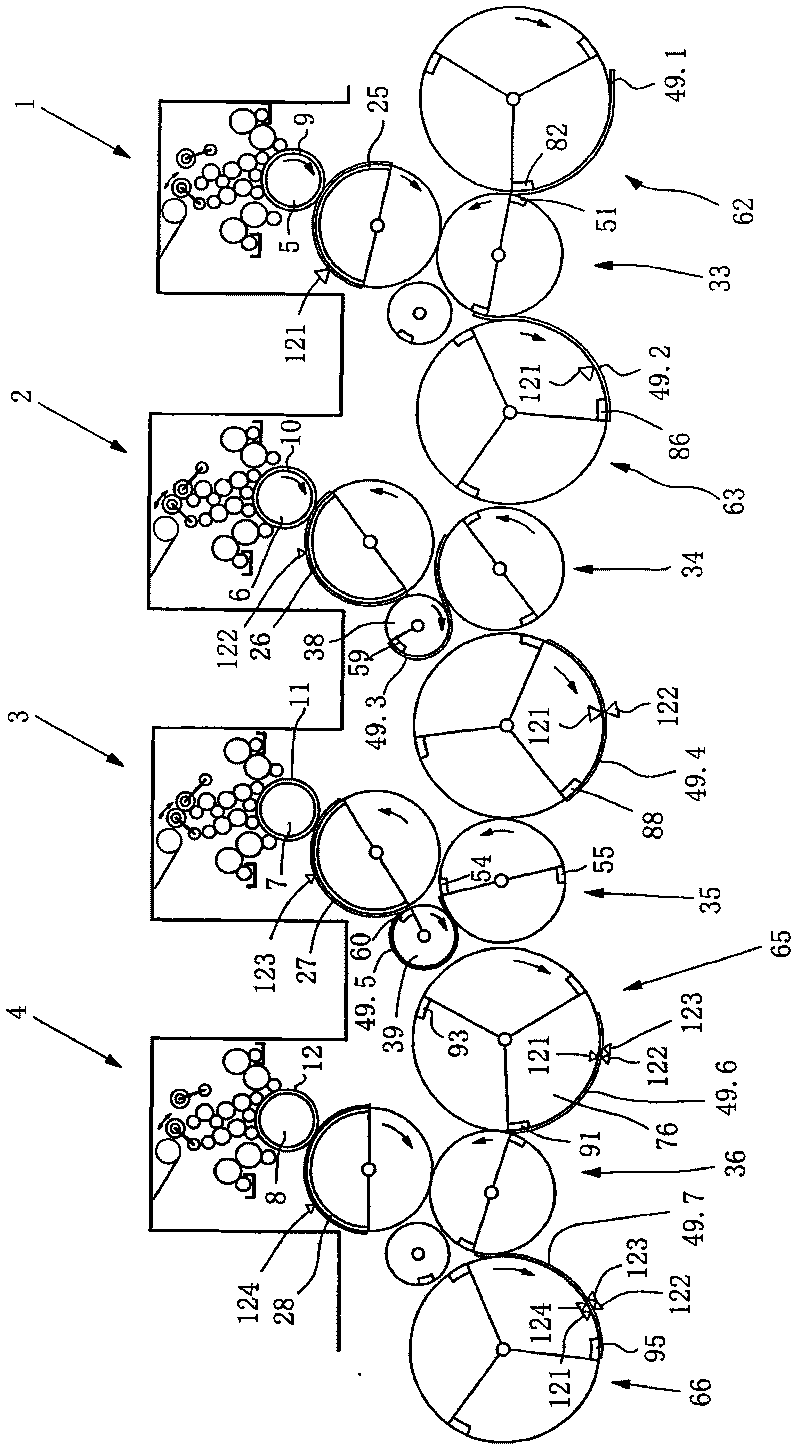

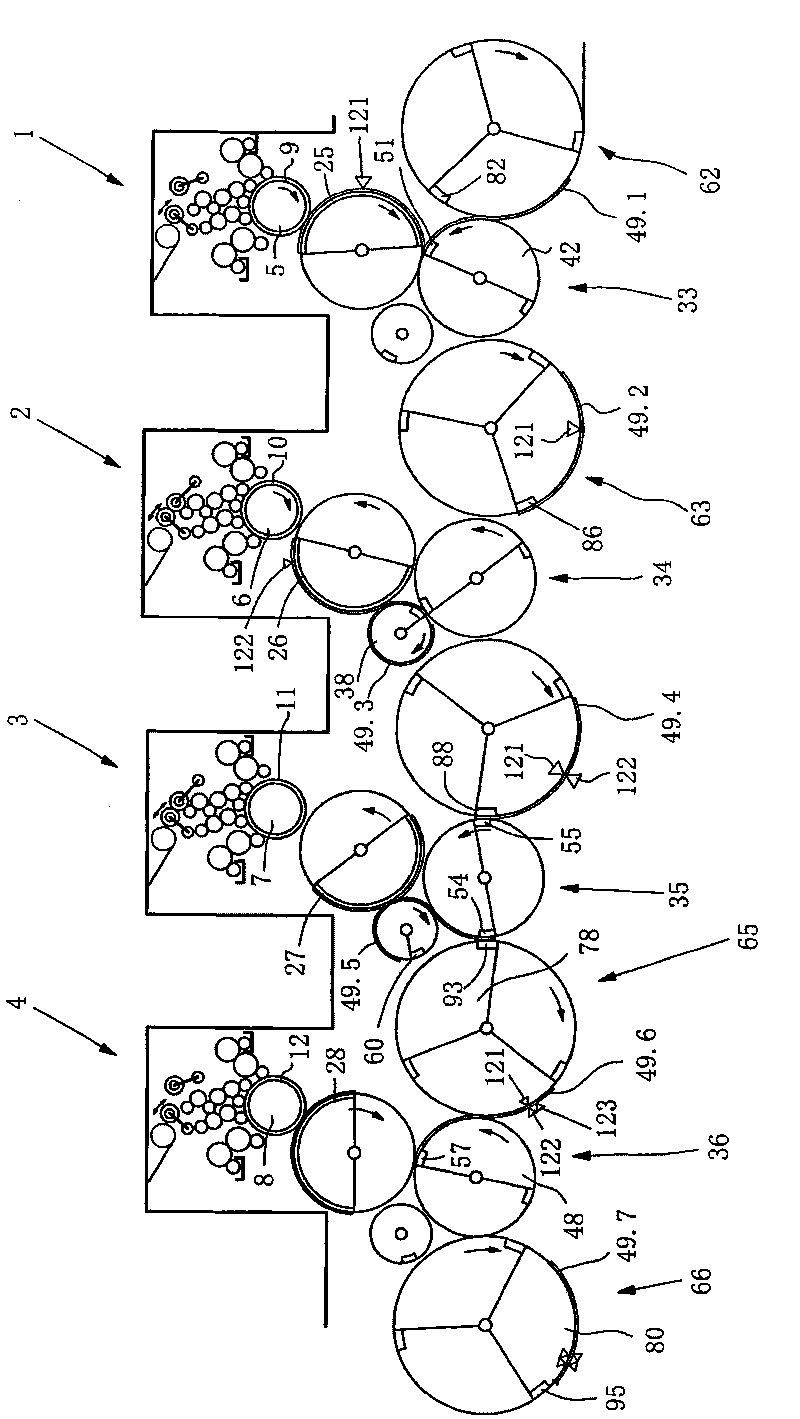

[0035] Figures 1.1 to 1.4Four printing units 1 to 4 of a sheet-fed wet offset printing press arranged one behind the other horizontally are shown. Each printing unit 1 - 4 contains a printing plate cylinder 5 - 8 which has printing plates 9 - 12 . The printing plates 9-12 each lie on an effective diameter D. Furthermore, each printing unit 1-4 contains a transfer cylinder 13-16 which is twice as large. Two semi-cylindrical sections 17 - 24 are formed on the transfer rollers 13 - 16 . In the sections 18, 19, 21 and 24, elastic coverings 25-28 are mounted on the transfer rollers 13-16. The linings 25 - 28 each lie on an effective diameter 2*D. In the sections 17, 20, 22, 23, the transfer cylinders 13-16 have surfaces 29-32 which do not transfer printing ink. Furthermore, each printing unit 1-4 contains a double-sized impression cylinder 33-36 and a double-sized impression cylinder 37-40. The impression cylinders 33 - 36 each have in two semi-cylindrical sections 41 - 48 a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap