Cooling filter layer of condensed aerosol fire extinguishing equipment

A filter layer and cooling layer technology, applied in the direction of filtration separation, dispersed particle filtration, fire protection equipment, etc., can solve the problems of loose cooling layer structure, high outlet temperature of hot aerosol fire extinguishing agent, loose module structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

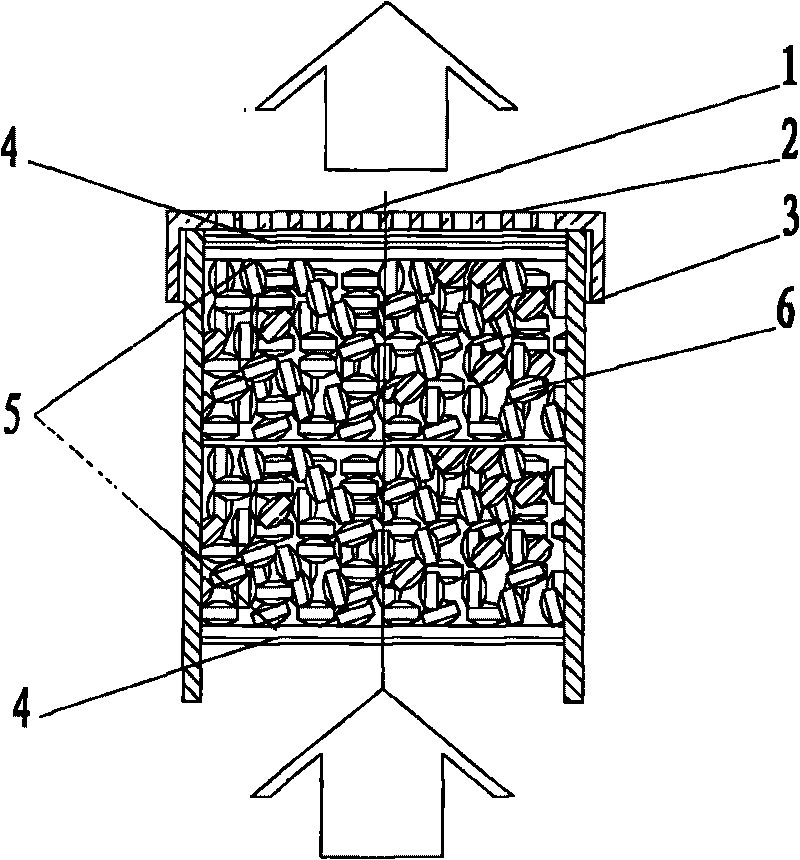

[0016] The cooling filter layer of a kind of thermal aerosol fire extinguishing equipment of the present invention comprises the sealing cover 2 that has through hole 1, cylinder body 3, baffle plate 4, wire mesh 5, and the cooling layer module that is set in cylinder body 3 is free The stacked columnar porous ceramic modules 6 are loaded with chemical coolant.

[0017] combine figure 1 When the prefabricated porous ceramic deposits or infiltrates the chemical coolant, when the high-temperature aerosol formed by combustion passes through the cooling filter layer, the chemical coolant absorbs heat and produces a decomposition reaction, thereby reducing the outlet temperature of the aerosol fire extinguishing agent. Due to the free accumulation of columnar The complex gas transmission channel of the porous ceramic module makes the sparks and residues produced by combustion stay in the filter layer composed of porous ceramics. At the same time, it also avoids the loosening of th...

Embodiment 2

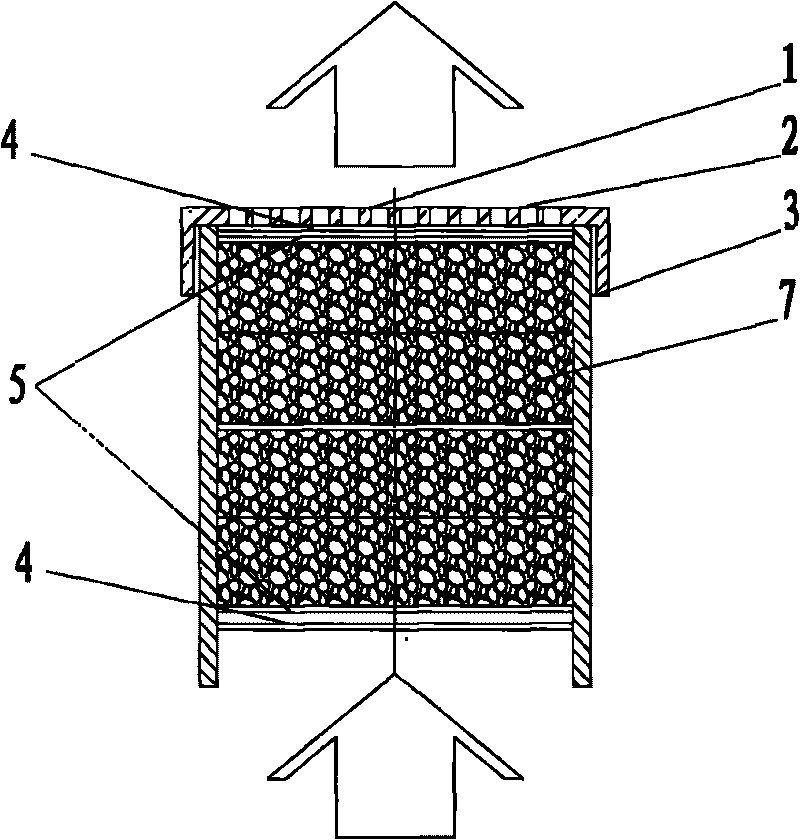

[0019] The cooling filter layer of a hot aerosol fire extinguishing equipment of the present invention includes a sealing cover 2 with a through hole 1, a cylinder body 3, a baffle plate 4, and a wire mesh 5, and the cooling layer module arranged in the cylinder body 3 is a whole The molded ceramic foam module 7 carries cold aerosol fire extinguishing agent on the ceramic module.

[0020] combine figure 2 , when the prefabricated ceramic foam deposits or infiltrates chemical coolant, when the high-temperature aerosol formed by combustion passes through the cooling filter layer, the chemical coolant absorbs heat and produces a decomposition reaction, thereby reducing the outlet temperature of the aerosol fire extinguishing agent. Due to the foam ceramic module The complex filter channel makes the sparks and residues produced by combustion stay in the filter layer composed of foam ceramics.

Embodiment 3

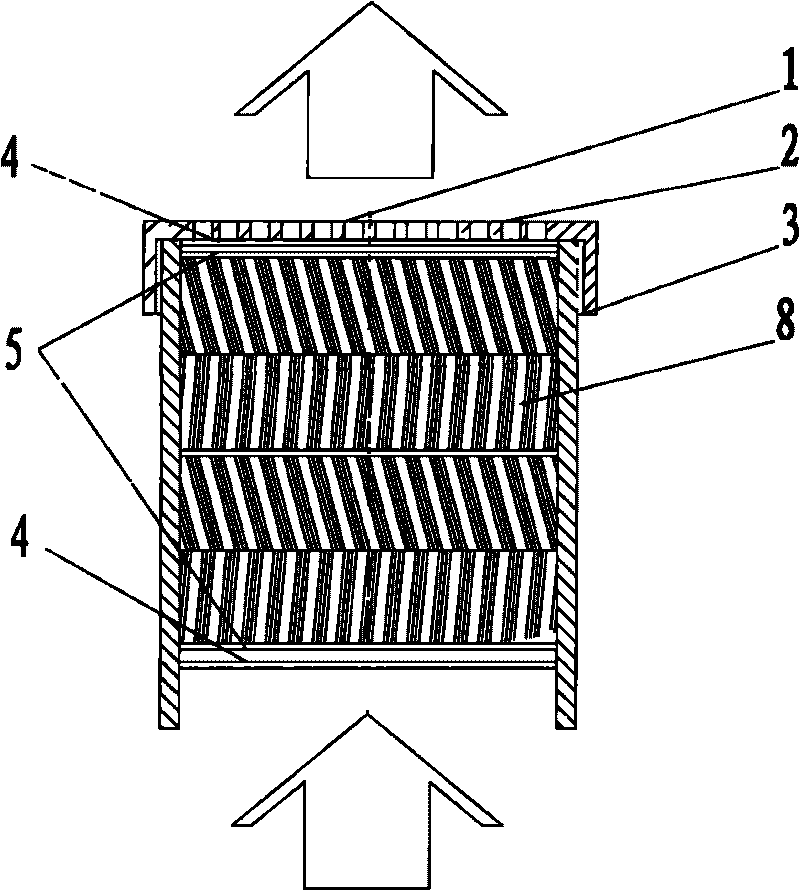

[0022] The cooling filter layer of a hot aerosol fire extinguishing equipment of the present invention includes a sealing cover 2 with a through hole 1, a cylinder body 3, a baffle plate 4, and a wire mesh 5, and the cooling layer module arranged in the cylinder body 3 is regular Array of honeycomb ceramic modules 8 .

[0023] combine image 3 , a chemical coolant or adsorbent is attached to the wall of the honeycomb ceramic channel that is integrally formed or combined. When the high-temperature aerosol formed by combustion passes through the honeycomb ceramic channel, the chemical coolant absorbs heat and generates a decomposition reaction, thereby reducing the aerosol fire extinguishing agent. The outlet temperature, or the use of adsorbents to selectively adsorb some toxic gases. Since the honeycomb ceramic is composed of relatively dense fine channels and the staggered connection between the mold layers, the sparks and residues produced by combustion cannot pass through ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap