Razor head

A razor and blade technology, which is applied in metal processing and other directions, can solve the problems of affecting the shaving effect, the blade becomes warped, and high cost, so as to achieve a good shaving effect and reduce the dead zone effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

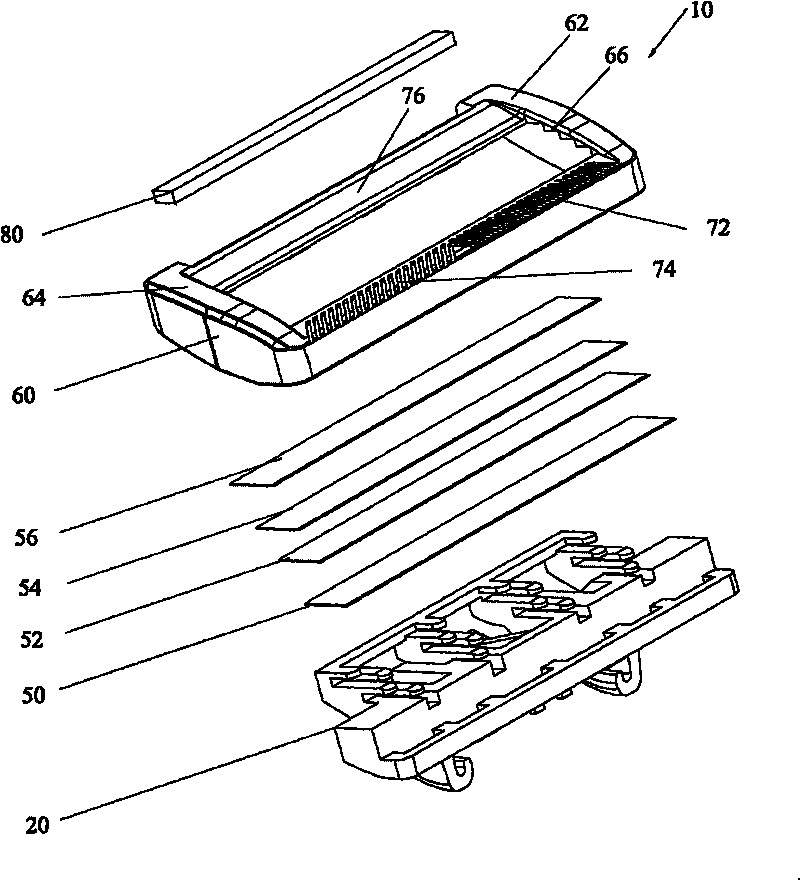

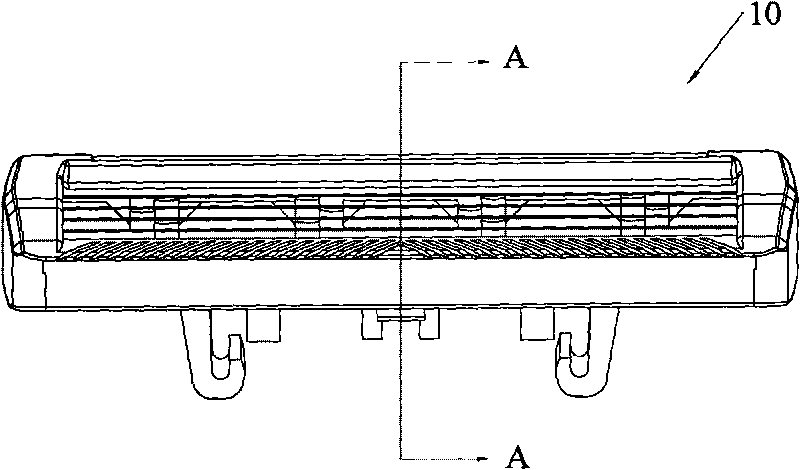

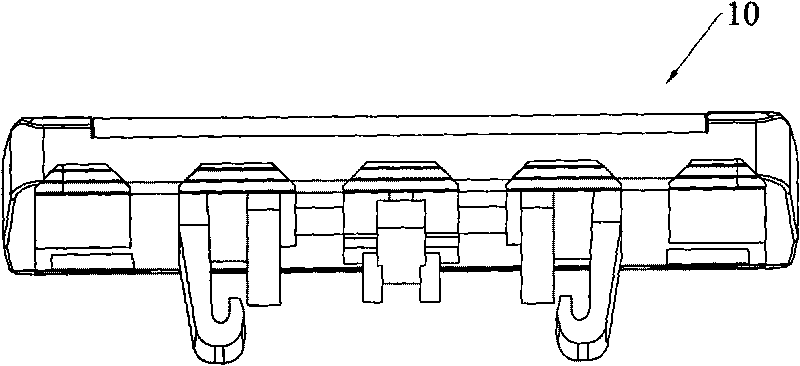

[0036] figure 1 An exploded view of a preferred embodiment of the razor head according to the invention is shown. The razor head 10 is suitable for being installed on a suitable handle to form a razor for shaving hair, and it is particularly suitable for use as a razor. The razor head 10 is easy to clean after shaving. In addition, the razor head 10 reduces the possibility of clogging of the gap between the blades during the shaving process, and therefore reduces the number of cleanings during the shaving process, even without cleaning during the shaving process. Such as figure 1 As shown, the razor head 10 includes a blade holder 20, 4 blades 50, 52, 54, 56, a gland 60, and a mechanism for guiding hair to the blades (in figure 1 Shown as a herringbone groove 74) and a lubricating strip 80. See Figure 2-6 As described in detail below, the four blades are inserted into the space formed by the ribs of the blade holder 20, and the gland 60 is connected to the blade holder (for e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com