Weaving process for anti-electromagnetic-radiation air layer weft knitted fabric

A knitted fabric, air layer technology, applied in weft knitting, knitting, textiles and papermaking, etc., can solve the problems of high price, influence of fiber main performance, electromagnetic radiation leakage, etc., and achieve strong electromagnetic radiation resistance and electromagnetic shielding efficiency. High, avoid the effect of high buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

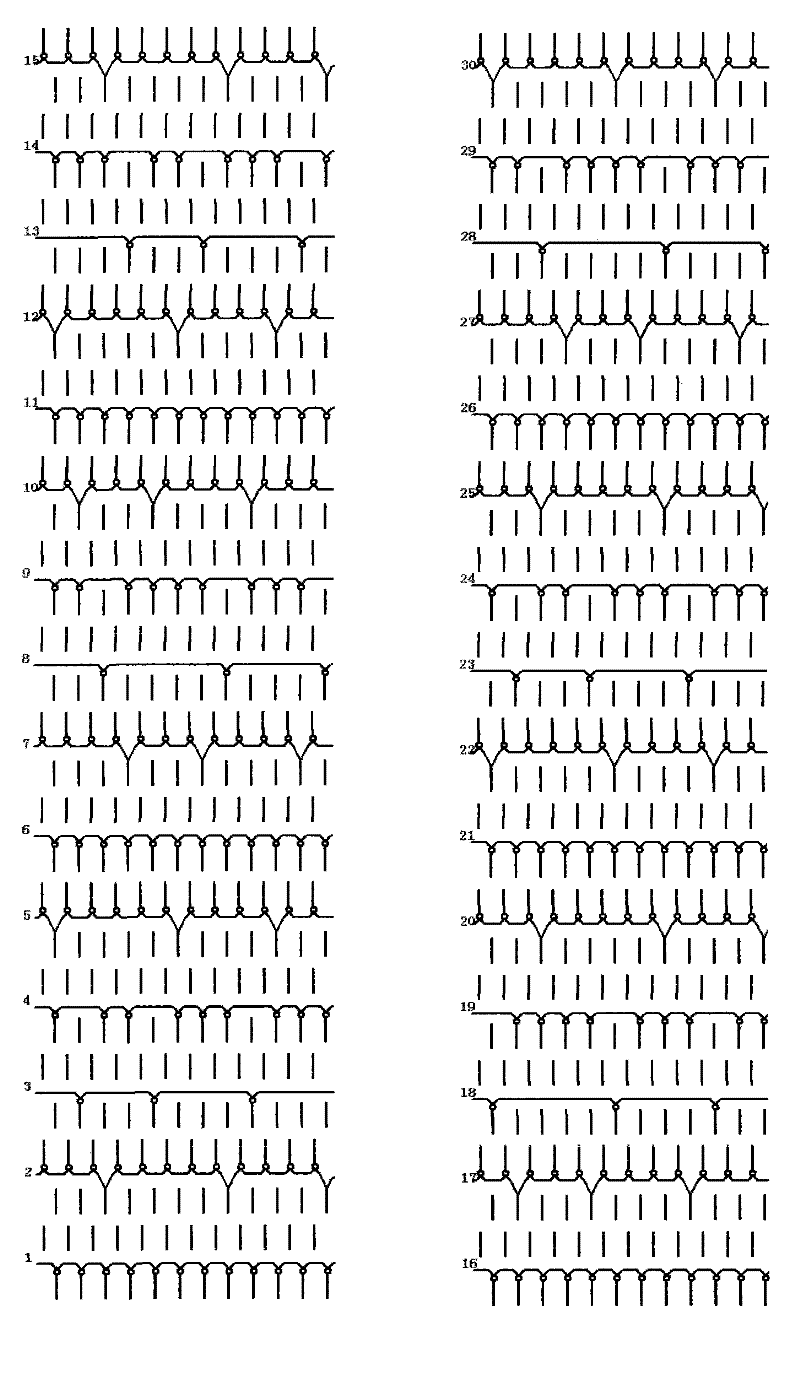

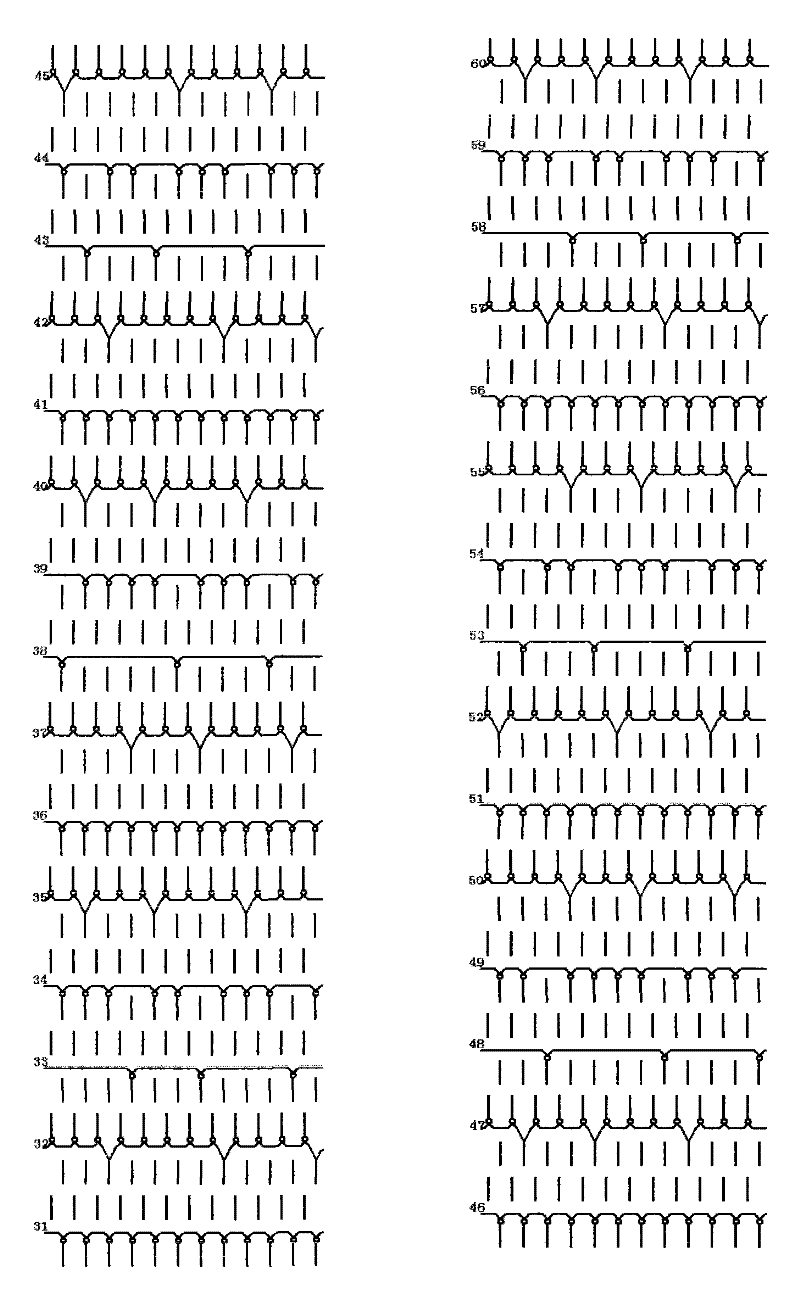

[0012] A weaving process of anti-electromagnetic radiation air layer weft-knitted fabric, the front and back of the knitted fabric are made of cotton or polyester-cotton blended as raw material through loom weaving, the invention adopts double-sided small jacquard air layer structure to produce the weave of the fabric, In the knitted fabric, stainless steel filaments are woven in parallel, and the stainless steel filaments form coils in a local loop on the front of the fabric, while the floating length between adjacent stainless steel filament coils is in the middle of the air layer structure. As shown in Figure 1, the production process of the double-sided dobby air layer structure refers to the loom in the 37, 40, 42, 45, 47, 50, 52, 55, 57, 60 Weave cotton or polyester-cotton blended raw materials to form the reverse side of the fabric, No. 1, 3, 4, 6, 8, 9, 11, 13, 14, 16, 18, 19, 21, 23, 24, 26, 28, 29, 31, 33, 34, 36, 38, 39, 41, 43, 44, 46, 48, 49, 51, 53, 54, 56, Road...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com