Touch panel, touch electronic device and assembly method thereof

An electronic device and assembly method technology, applied in the direction of electrical digital data processing, instrumentation, data processing input/output process, etc., can solve the problem that the thickness cannot be thinned, the production process yield rate of touch-sensitive electronic devices is not high, touch control In order to reduce the weight of conventional electronic devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

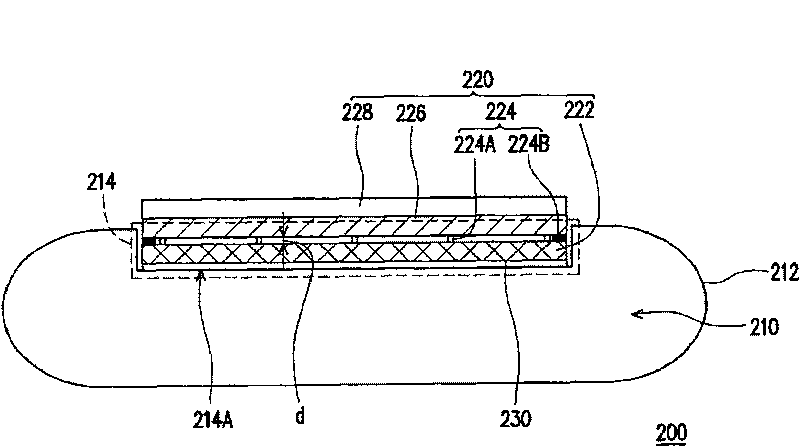

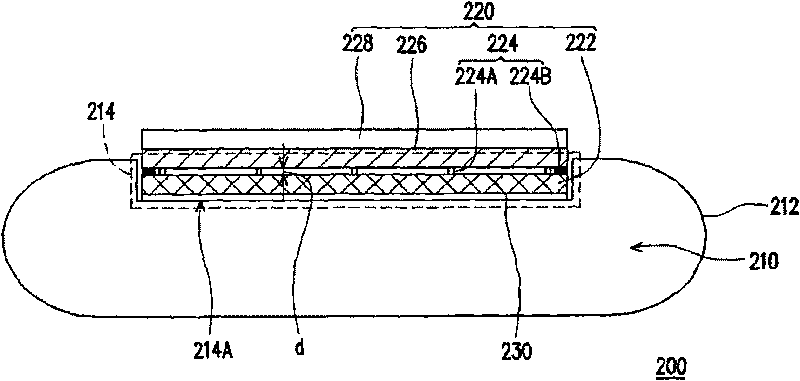

[0042] figure 2 Shown is a touch-sensitive electronic device according to an embodiment of the present invention. Please refer to figure 2 , the touch electronic device 200 includes an electronic device body 210 and a touch element 220 . The electronic device body 210 has an outer casing 212 , and the outer casing 212 has an accommodating portion 214 . In practice, the bottom surface of the accommodating part 214 is a transparent accommodating surface 214A, wherein the accommodating surface 214A can directly constitute a part of the outer shell 212 when the outer shell 212 is formed, or can be pre-formed when the outer shell 212 is formed. After forming an opening at the bottom of the accommodating portion 214 , another transparent material plate is used to cover the opening in a secondary process to form the accommodating surface 214A. The touch element 220 is embedded in the accommodating portion 214 and includes a first conductive film layer 222 , an isolation componen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com