Method for adjusting hot-pressing apparatus

An adjustment method, technology of hot pressing equipment, applied in the direction of chemical instruments and methods, lamination, presses, etc., can solve problems such as not being able to meet the requirements of the work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below with reference to the accompanying drawings and in combination with preferred embodiments.

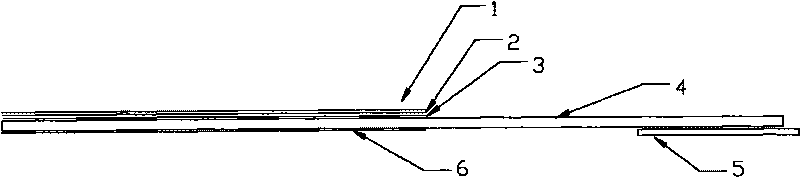

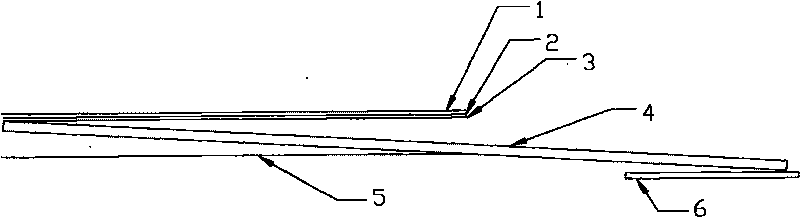

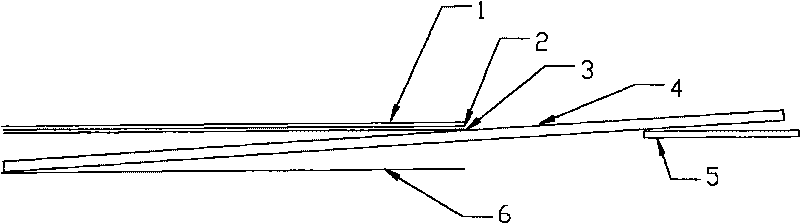

[0023] figure 1 A working schematic diagram under normal working conditions is shown. The hot pressing equipment of the present invention has a pressing head 1 , a load conveyor 5 supporting a plasma display panel 4 and a supporting body 6 . The adjustment method of the present invention includes: under the working state, pad the pressure-sensitive paper 3 between the display screen 4 and the indenter 1 and the silicon belt 2, lift the indenter 1 after pressing it down, and press the pressure-sensitive paper 3 on the load conveyor The color display difference between the 5 side and the support body 6 side is to adjust the height of the support body 6 until the color display is uniform.

[0024] Such as figure 1 As shown, under normal working conditions, the level of the load conveyor 5 and the support body 6 is basically...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com