Mooring winch and a method for controlling a cable of a mooring winch

A mooring and winch technology, applied to clockwork mechanism, hoisting device, ship, etc., can solve the problems of ship damage, mooring rope failure, personnel danger, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

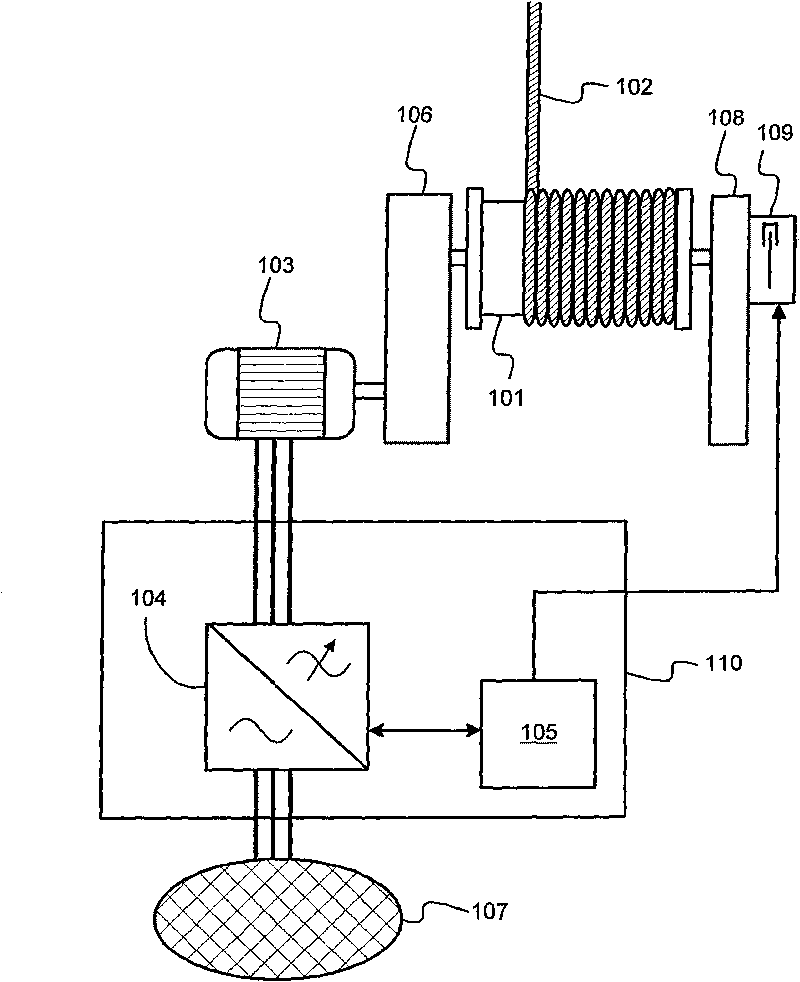

[0029] figure 1 A mooring winch according to one embodiment of the invention is shown. The mooring winch includes a drum 101 for winding a mooring rope 102, and an AC motor 103 for driving the drum. The AC motor may be, for example, an induction motor or a permanent magnet synchronous motor. figure 1 The mooring winch 1 shown has a gearbox 106 arranged between the alternating current motor 103 and the drum 101 . The drum is supported by the gearbox and bearing housing 108 . Depending on the dimensioning of the AC motor and the dimensioning of the mandrel, it is also possible to have a direct drive mandrel without a gearbox. The mooring winch includes a frequency conversion device 104 that supplies electric power to an AC motor 103 . The frequency conversion device is connected to a power grid 107, which may be, for example, an on-board power grid. The mooring winch comprises a control unit 105 arranged to control the frequency conversion means dependent on the indication ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap