Adjustable orifice plate device and throttling governing method using same

A throttling orifice, adjustable technology, applied in valve device, valve details, valve shell structure and other directions, can solve the problem of fixed or unadjustable throttling area, and achieve the effect of large area adjustment ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Hereinafter, specific embodiments of the present invention will be described in conjunction with the accompanying drawings.

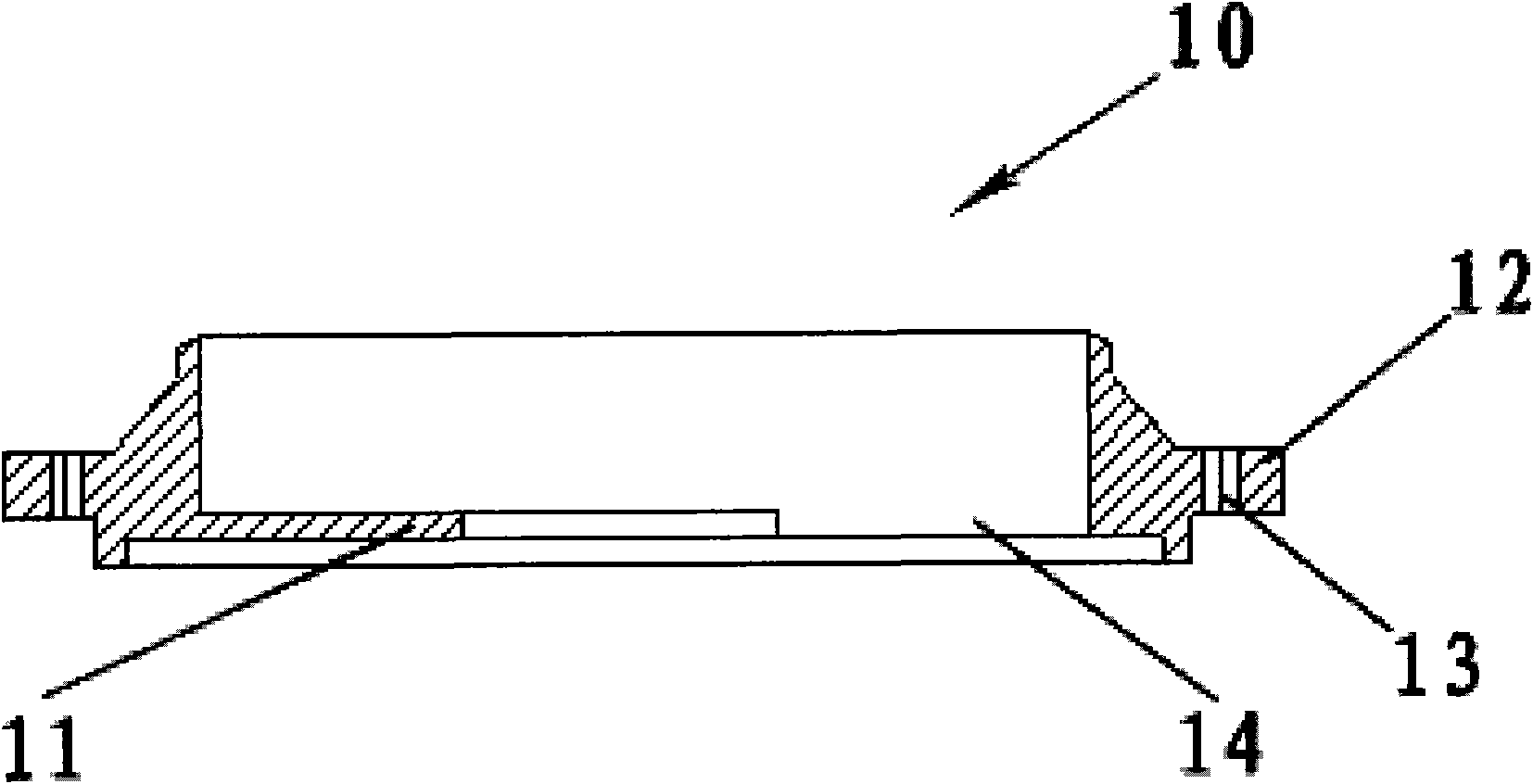

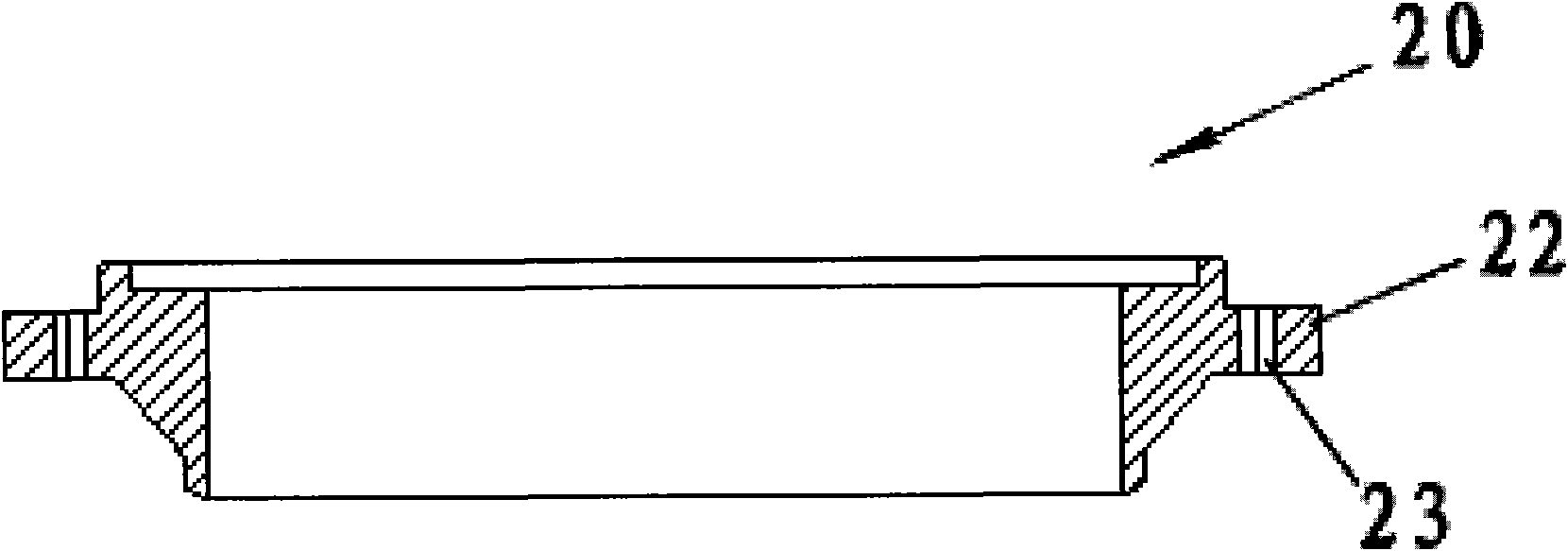

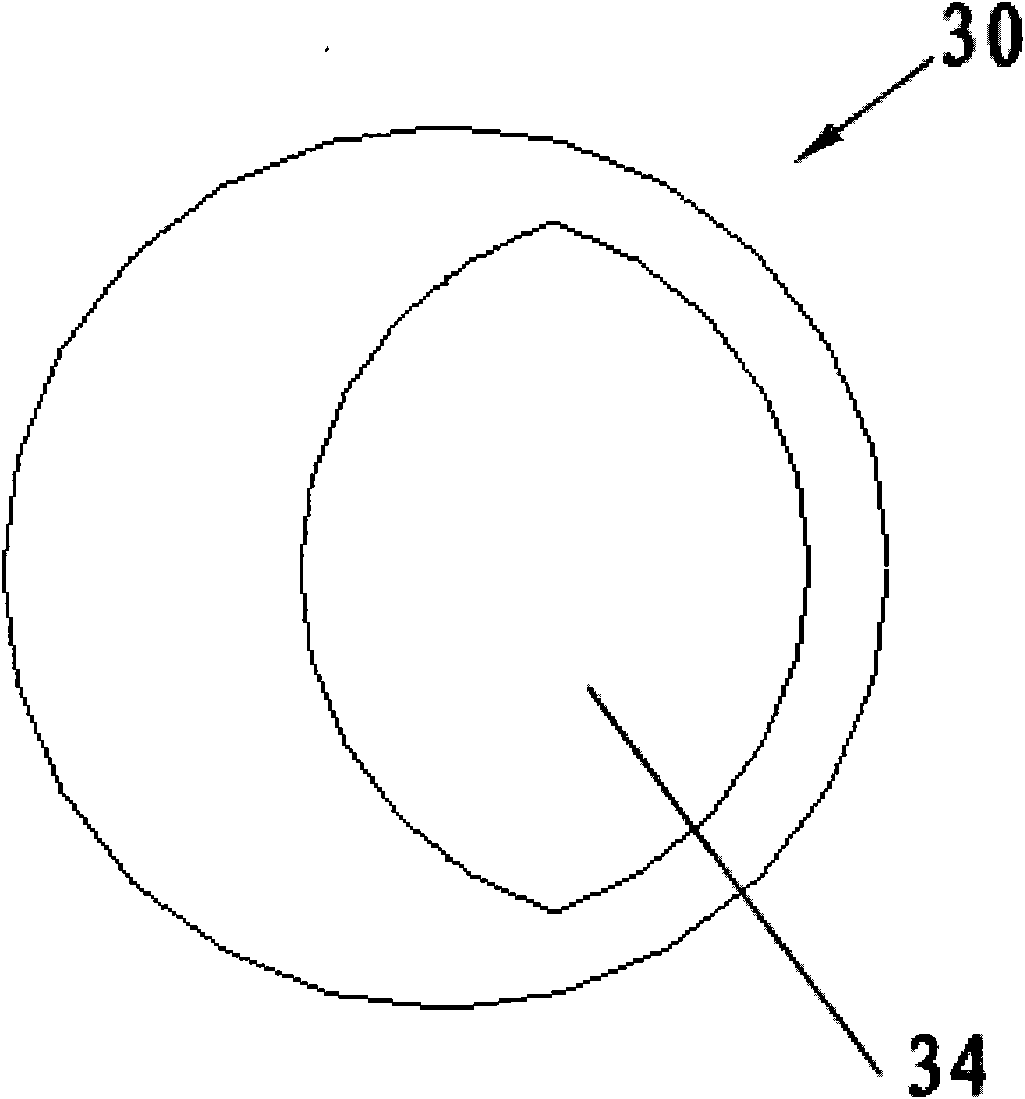

[0037] Such as Figure 1-Figure 4 As shown, the adjustable orifice device of the present invention includes: a flange with orifice 10, a flange without orifice 20, and an orifice 30; in addition, although not shown, the adjustable orifice device also includes There are washers, bolts and nuts etc.

[0038] Such as figure 1 As shown, the flange 10 with a throttle hole is internally provided with a throttle baffle 11 that reduces the flow area, so that a first flow hole 14 is formed on the plane where the throttle baffle 11 is located. A first flange 12 protrudes from the outer wall of the flange with orifice 10 in the radial direction, and the first flange 12 is provided with at least two first through holes 13 penetrating in the axial direction.

[0039] Such as figure 2 As shown, the non-restricted flange 20 has a second flange 22 protrudin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com