A drop test device

A technology of testing device and fixing device, applied in the direction of measuring device, impact test, machine/structural component testing, etc. The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

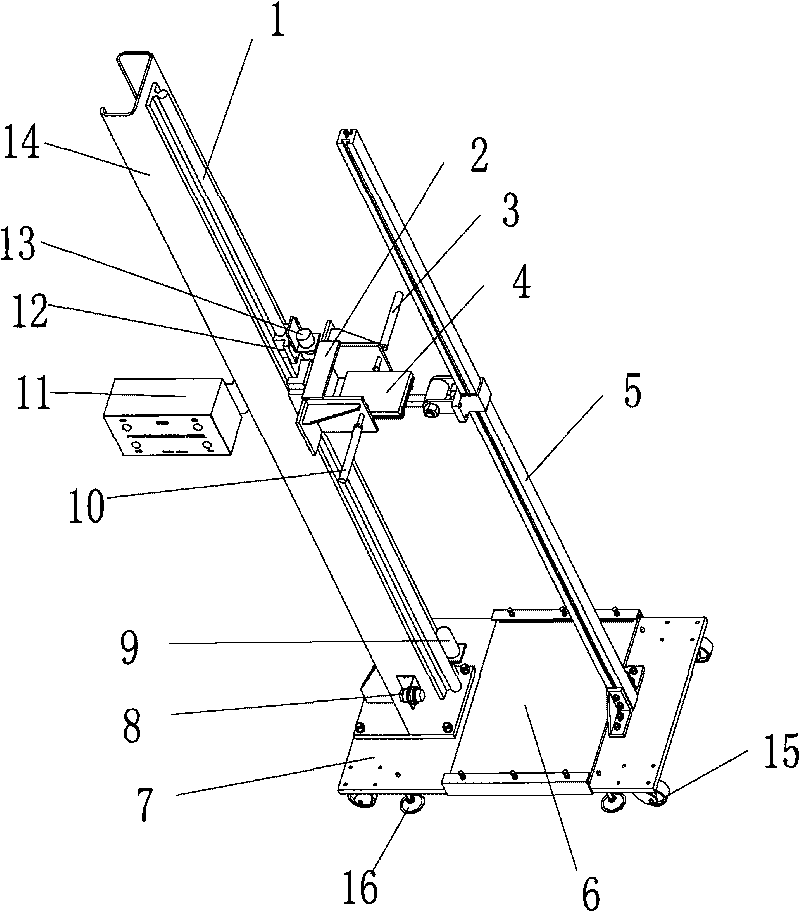

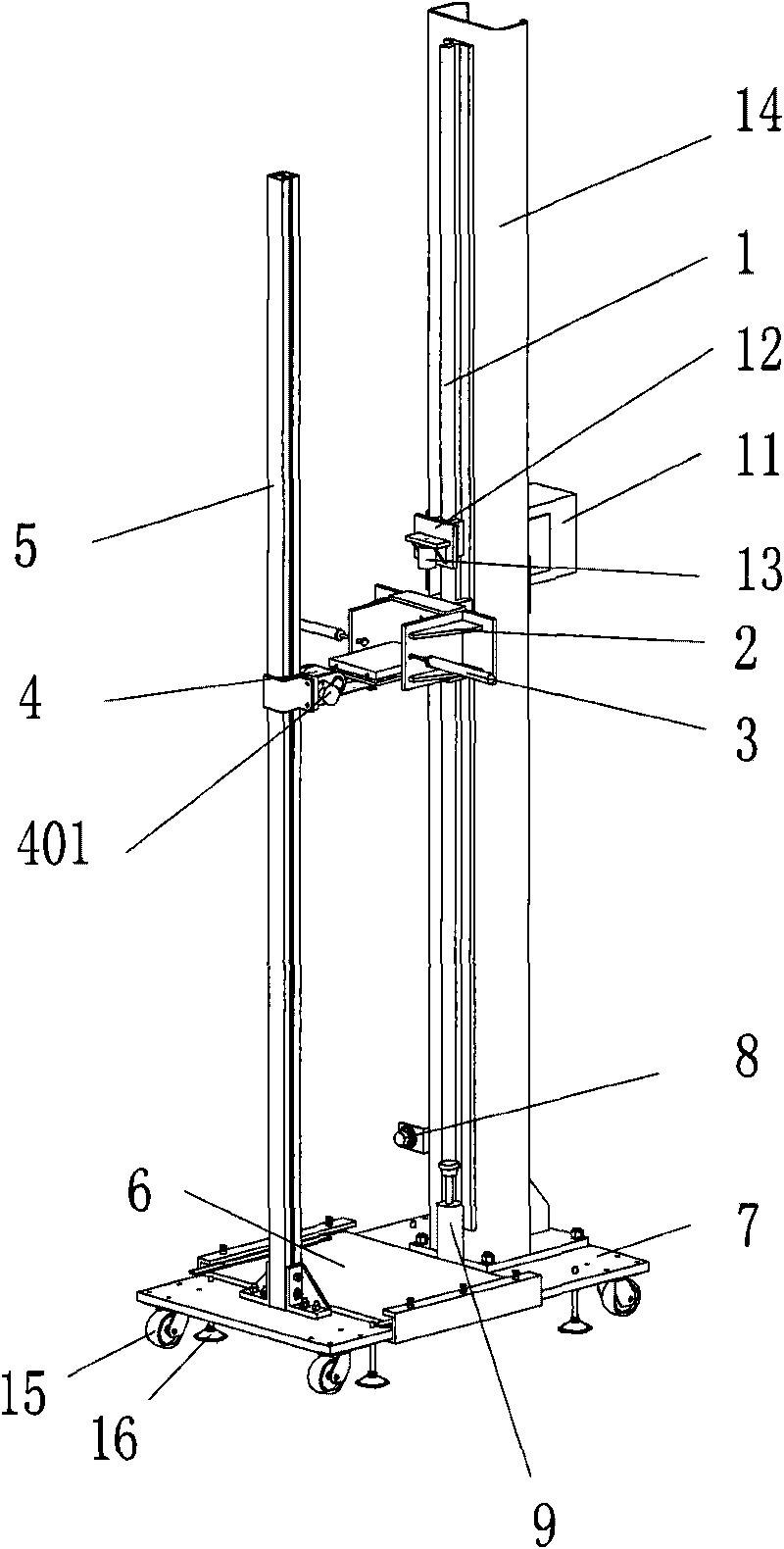

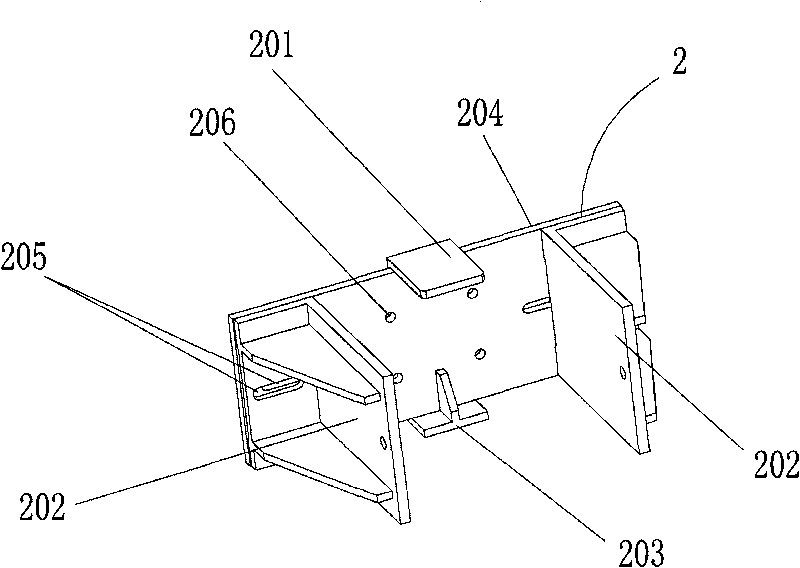

[0021] Such as figure 1 with figure 2 A drop test device for a mobile hard disk is shown, including a base 7, a support beam 14, a benchmark 5, a control cabinet 11, a fixture 2, a fixing device, a buffer device, an induction switch 8, a backing plate 6, and an object placement table 4 , rollers 15 and supporting feet 16, the fixing device includes a fixed base 12 and an electromagnet 13, and the buffering device includes a spring buffer 8 fixed on the base 7.

[0022] The supporting beam 14 is arranged in parallel with the pole 5, and is vertically fixed on the base 7 through bolt connection. The bottom of the base 7 is provided with four supporting feet 16 and four rollers 15. During the test, the supporting feet 16 prop up the entire testing device, and the level of the base can be adjusted by rotating each supporting foot 7. After the supporting feet 16 are retracted, the test device can be supported and moved by the rollers 15 .

[0023] The support beam 14 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com