Front-opened wafer box for fixing wafer restriction part module in mode of rotating, resisting and fixing

A restrictor and front-opening technology, which is applied in the field of fixing the wafer restrictor module of the front-opening wafer box, can solve problems such as looseness, difficult cleaning of particulate dust, and inability to reduce the size of the wafer box. The effect of shortening the size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a more complete and clear understanding of the technical content used in the present invention, the purpose of the invention and the effects achieved, a detailed description will be given in conjunction with the accompanying drawings.

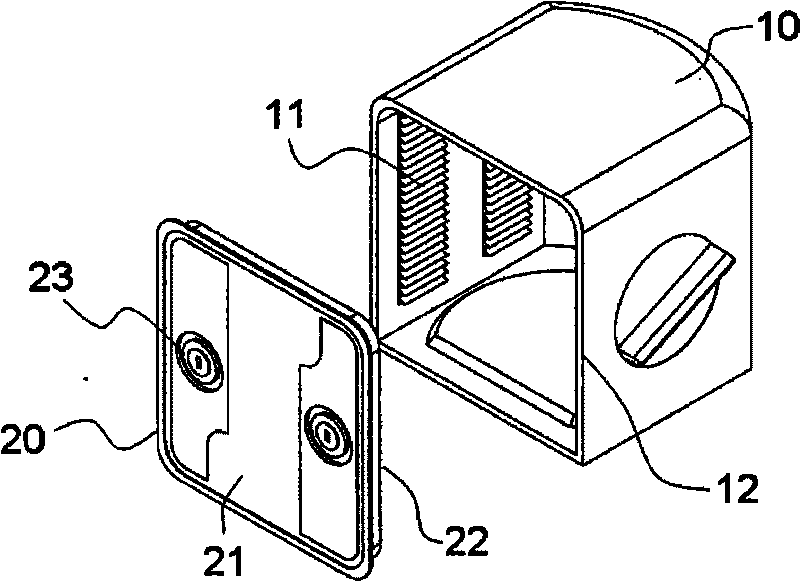

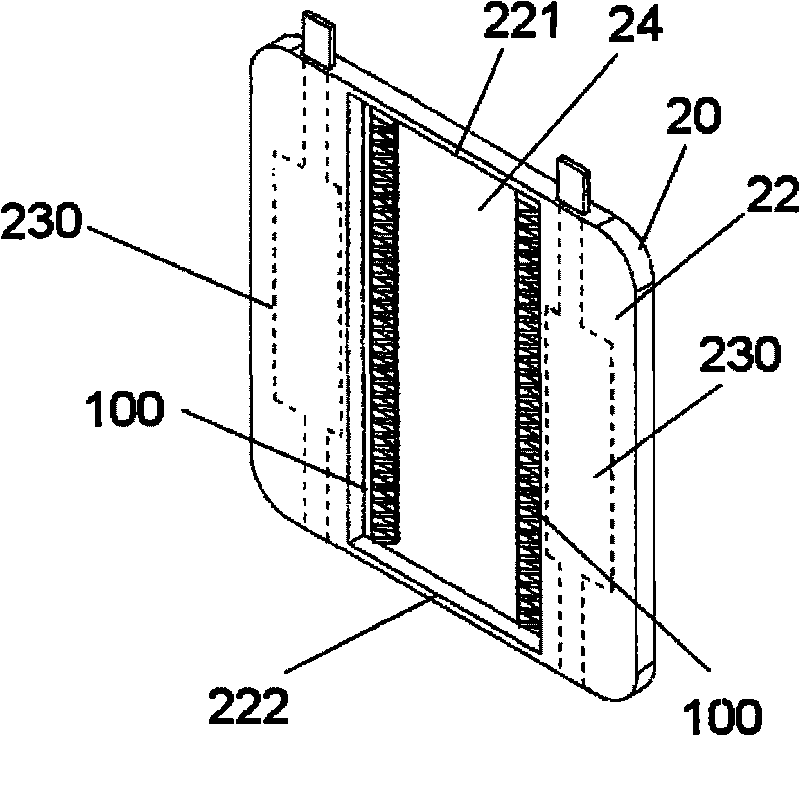

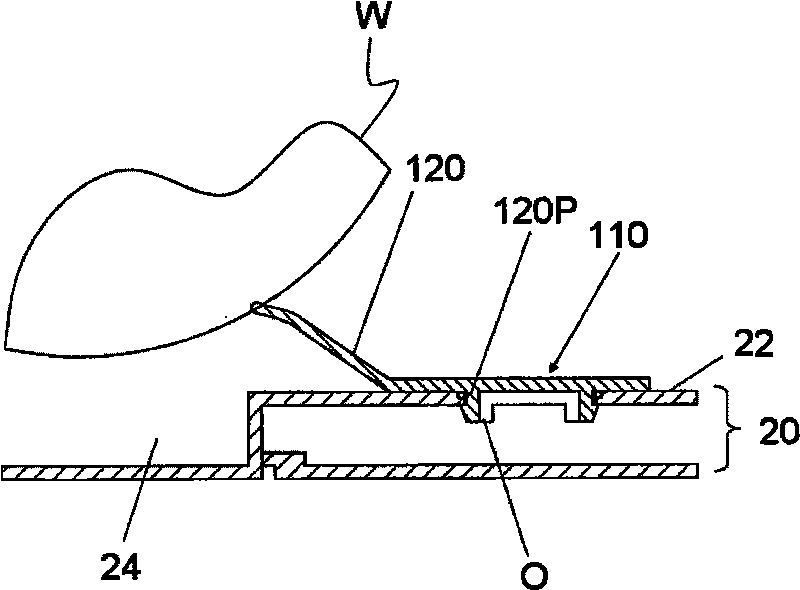

[0028] First, see Figure 4 Shown is a schematic diagram of a front-opening wafer cassette of the present invention. The front opening wafer box includes a box body 10 and a door body 20. A plurality of slots 11 are provided inside the box body 10 to accommodate a plurality of wafers, and an opening 12 is provided on one side of the box body 10. Wafer input and output are available. The door body 20 has an outer surface 21 and an inner surface 22, and a recessed area 24 is arranged at about the middle of the inner surface 22 of the door body 20. This recessed area 24 can further divide the inner surface 22 of the door body 20 into two convex portions. out of the platform 25, and a wafer restraint module 30 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com