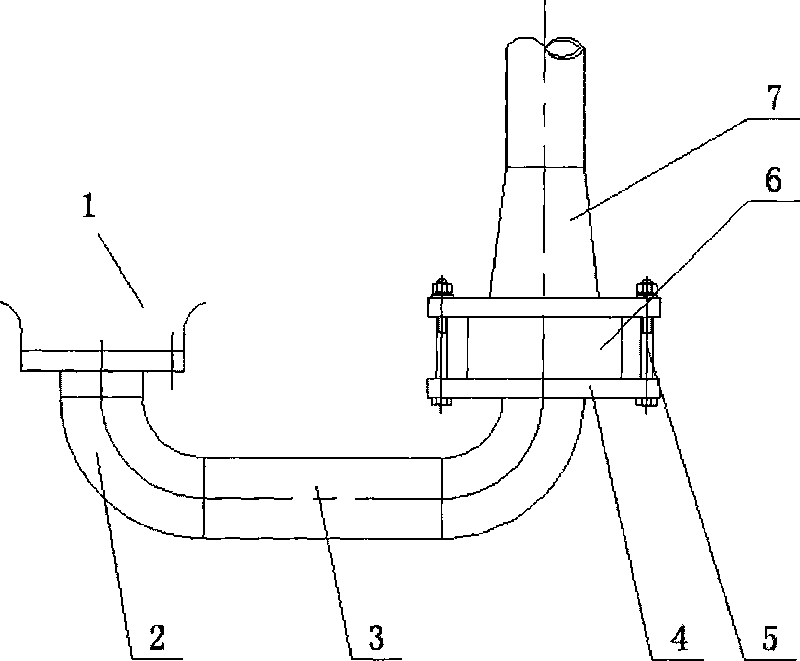

Check valve used for air compressor

A technology for check valves and air compressors, applied in safety valves, balance valves, control valves, etc., can solve problems such as poor sealing performance, aggravated pipeline safety hazards, and existing sealing hazards, so as to reduce pipeline connectors and pipes. Road leakage point, easy to install and connect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

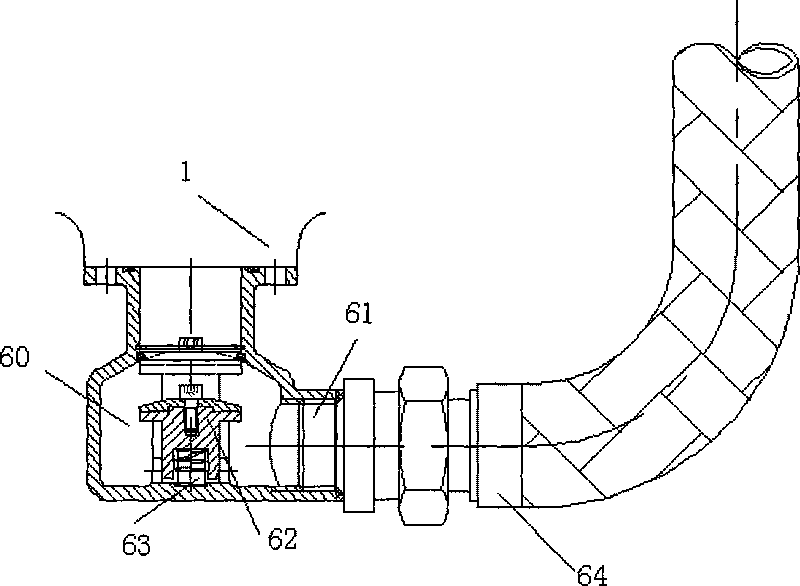

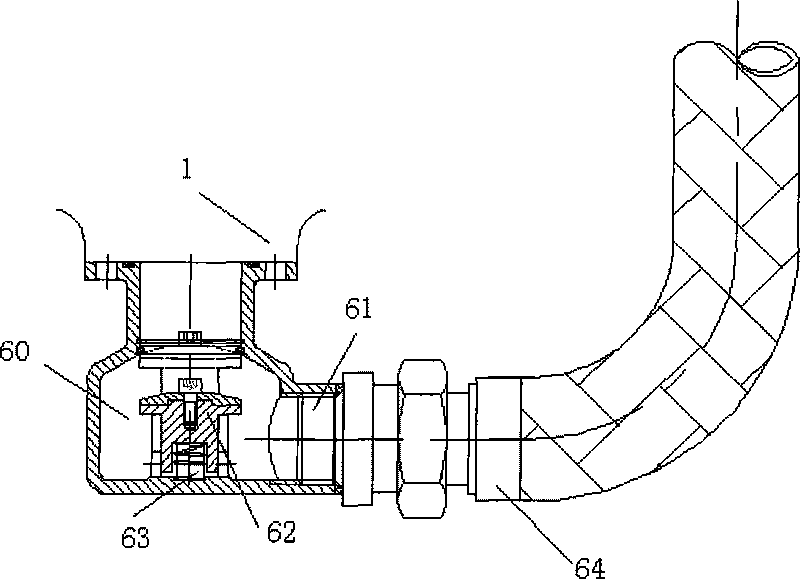

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0014] Depend on figure 2 It can be seen that the present invention includes: a body 60; the body 60 is directly connected to the air compressor exhaust port 1; the direction of the inlet and outlet 61 of the body 60 is at an angle of 90° to the direction of the air compressor exhaust port 1;

[0015] The body 60 further includes: a piston 62 communicating with the air compressor exhaust port 1 ; a return spring 63 is connected to the lower end of the piston 62 .

[0016] The present invention fully considers the phenomena such as swirl flow and cavitation when the compressed air passes through the valve channel, so as to minimize the pressure loss; on the premise of not reducing its safety, reliability and durability, the present invention directly connects the check valve to the The exhaust port of the air compressor; the direction of the in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap