Underground pipeline excavated pipe joint prestress connecting method

A technology of underground pipelines and connection methods, which is applied in the direction of pipes/pipe joints/fittings, pipeline laying and maintenance, mechanical equipment, etc., and can solve problems such as easy instability of pipe joints, lack of tensile properties, and disconnection between pipe joints. Achieve the effects of improving stiffness and overall stability of pipe joints, controlling water leakage and disconnection between pipe joints, and improving tensile capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

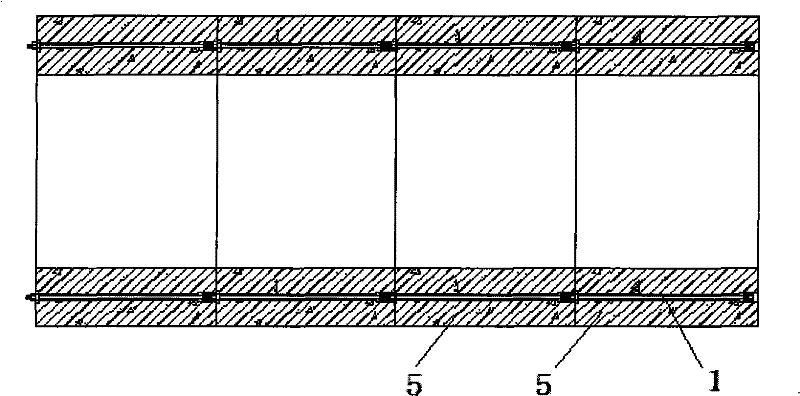

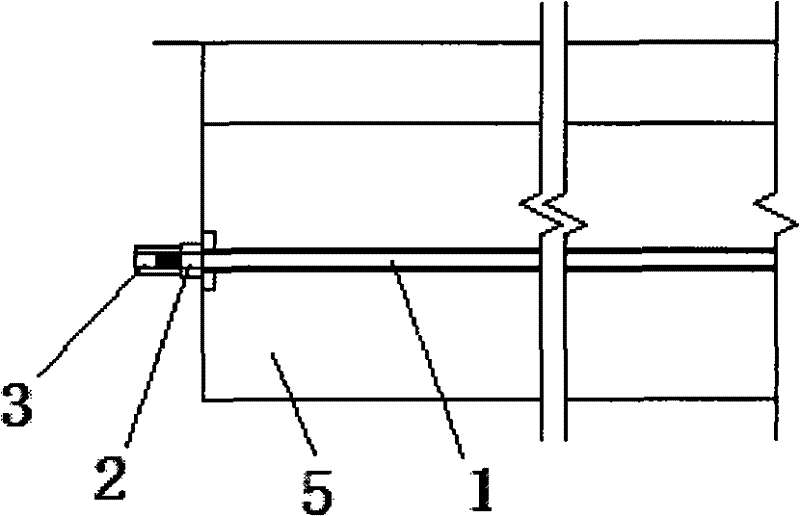

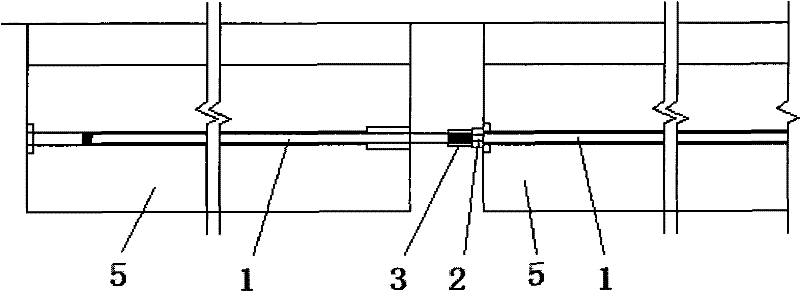

[0023] Such as Figure 1-Figure 7 As shown, a pipe joint prestressed connection method for underground pipeline excavation provided by the embodiment of the present invention includes the head of the pipe jacking machine and at least one pipe joint 5, which is characterized in that the pipe joint 5 is prestressed The reinforcing bars 1 are buried, and the pre-embedded reinforcing bars 1 extend to the front and rear ends of the pipe joint 5 to form an extension section. The connection steps of each pipe joint 5 are as follows:

[0024] 1) Lower the first section of pipe joint, and fix the pre-embedded reinforcement extension se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com