Wheel structure of horizontal jack

A jack and wheel technology, applied in the direction of lifting devices, can solve problems such as the influence of the service life of the jack and hinder the smooth movement of the jack, and achieve the effect of prolonging the service life and ensuring smooth movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

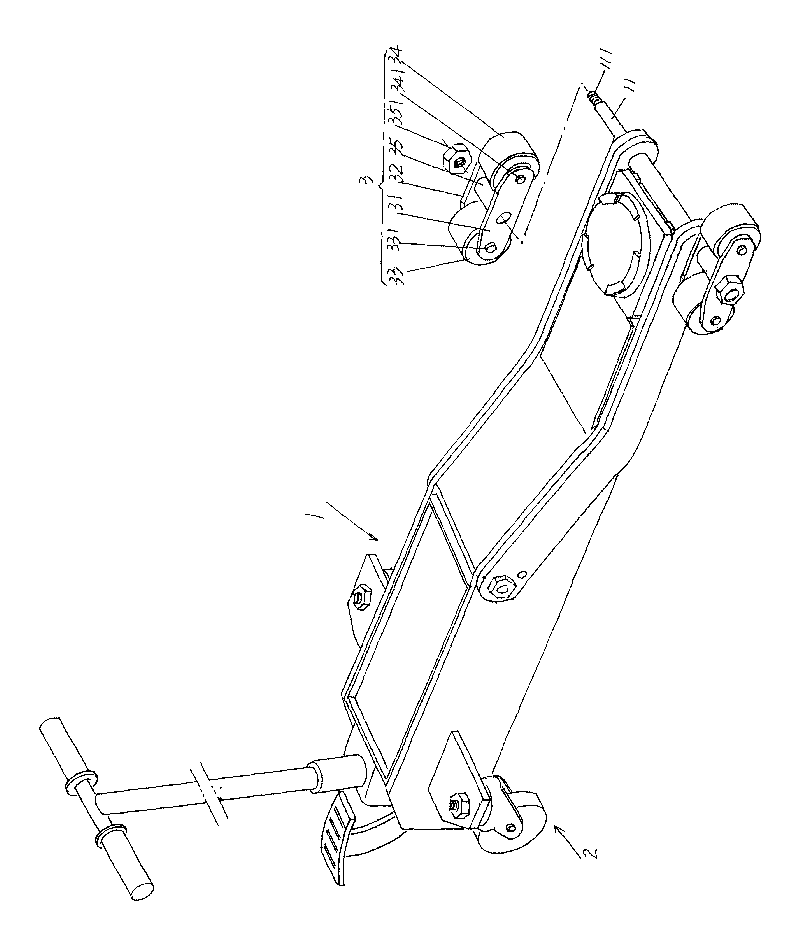

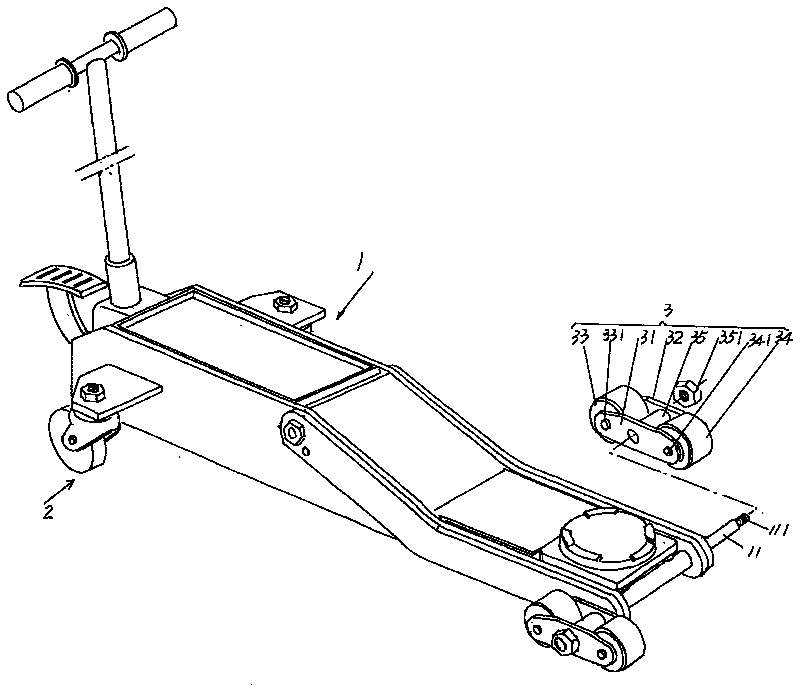

[0007] Please refer to the accompanying drawings, the jack body 1 of the horizontal jack provided belongs to the known technology, and a rear wheel 2 is respectively equipped on the corresponding two sides of the rear end (also called the tail) of the jack body 1. The front end, that is, the right end shown in the figure, has a roller shaft 11 , and the two ends of the roller shaft 11 extend laterally out of the jack body 1 and are each processed with threads 111 . As the technical gist of the present invention, the structure of each front wheel 3 that is arranged on the two ends of the roller shaft 11 has been reasonably improved, specifically: each front wheel 3 includes first and second roller frames 31, 32, first, second Two rollers 33,34 and axle sleeve 35, the first, the second roller frame 31,32 are parallel to each other, the first roller 33 is arranged on the first, the second roller frame 31,32 by the first roller pin 331 and rotates One end, and located between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com