Adjusting force detecting tool of safety belt height adjusting device

A technology for detecting tooling and high-profile devices, which is applied in the field of detection tooling for the adjustment force of seat belt high-profile devices, can solve the problems of inability to realize the operation of seat belt adjusters, prone to jamming, and low detection accuracy, so as to ensure smooth movement, High detection efficiency and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

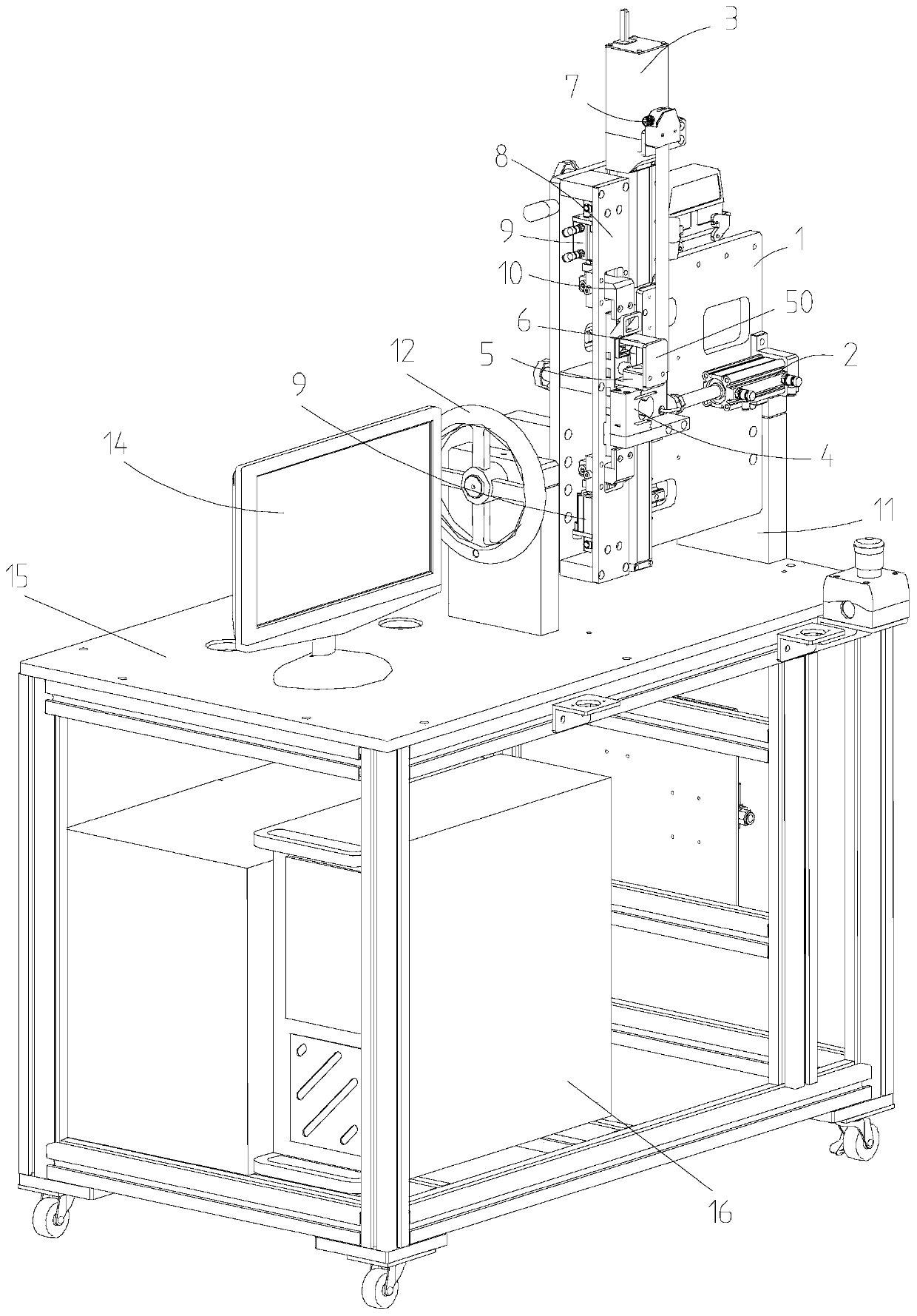

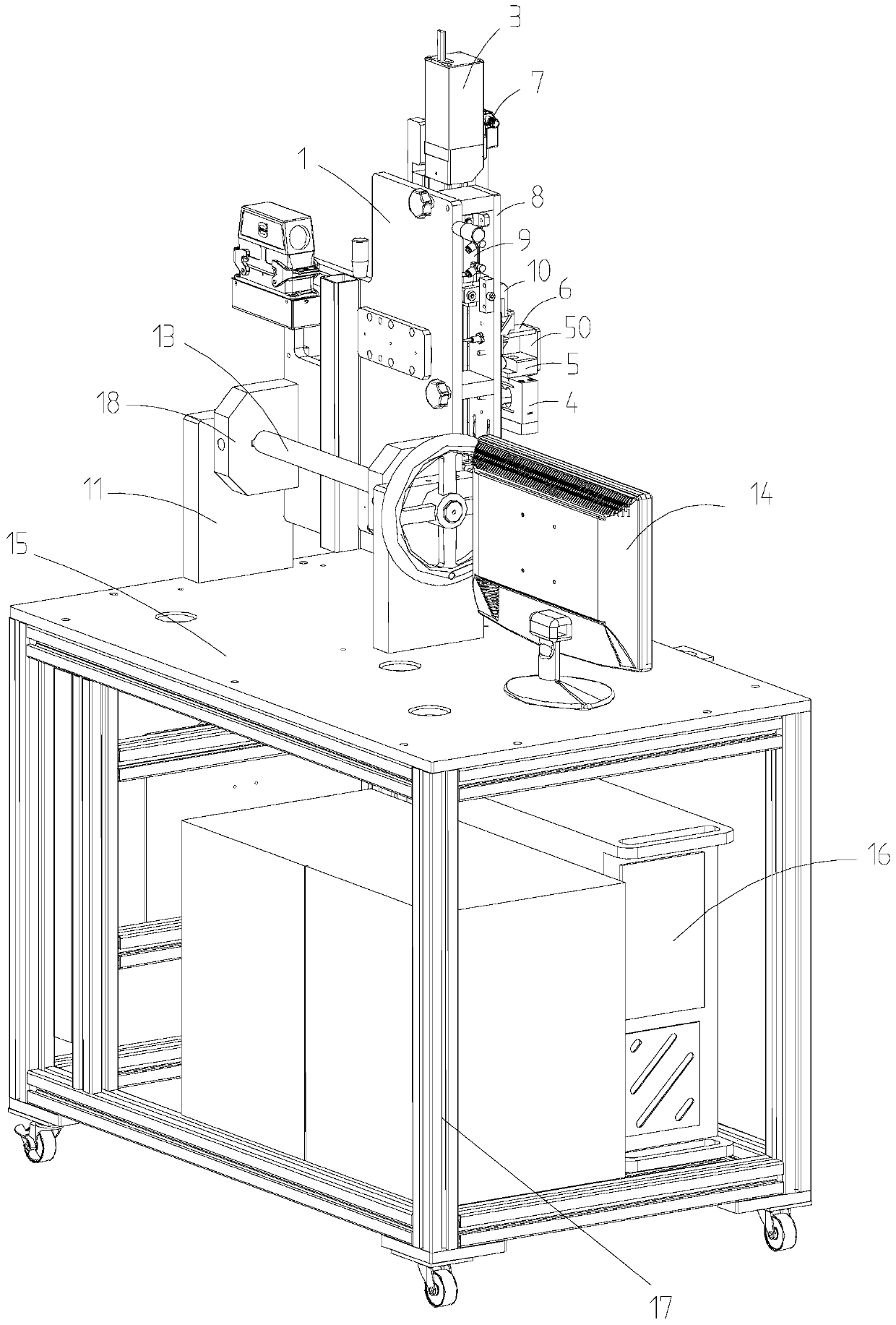

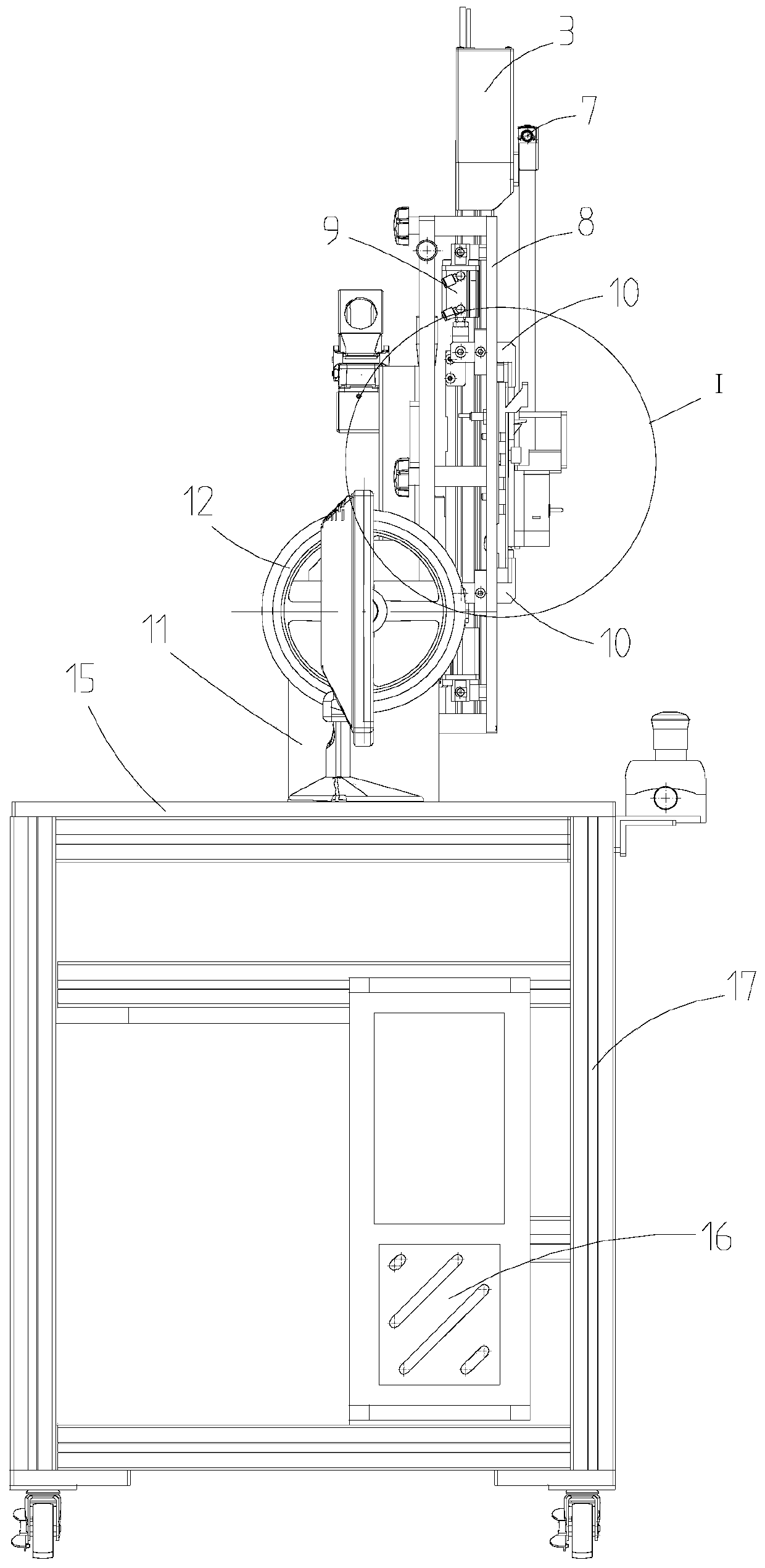

[0029] as attached figure 1 - attached Figure 7 The shown tooling for detecting the adjustment force of the seat belt height adjuster includes a rectangular profile frame 17 as a whole. The upper end of the profile frame 17 is connected to a worktable 15 on which a display 14 and two fixing plates 11 are fixed. , the profile frame 17 is placed with an industrial computer 16 . A rotating shaft 13 is rotatably connected between the two fixing plates 11, and one end of the rotating shaft 13 stretches out from the fixing plate 11, and an end extending out of the fixing plate 11 at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com