Toilet flushing mechanism

A technology for flushing toilets and water storage tanks, applied in the field of sanitary ware, can solve the problems of short life, inconvenience and unreliability, and achieve the effects of improving reliability and convenience, good reliability and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

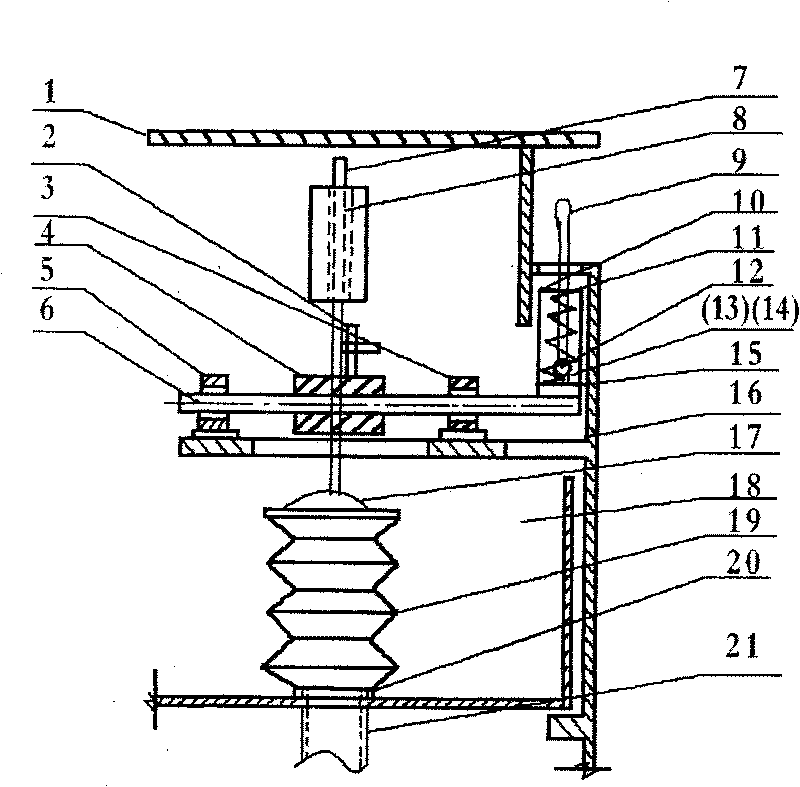

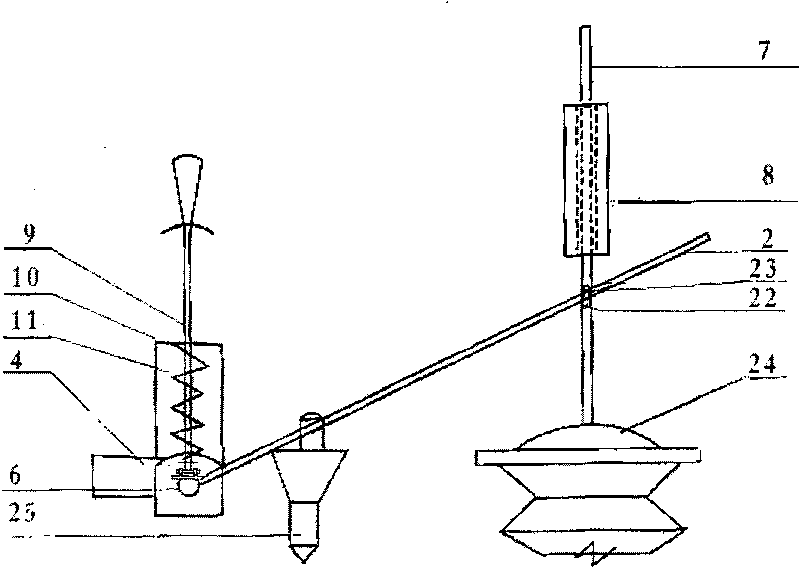

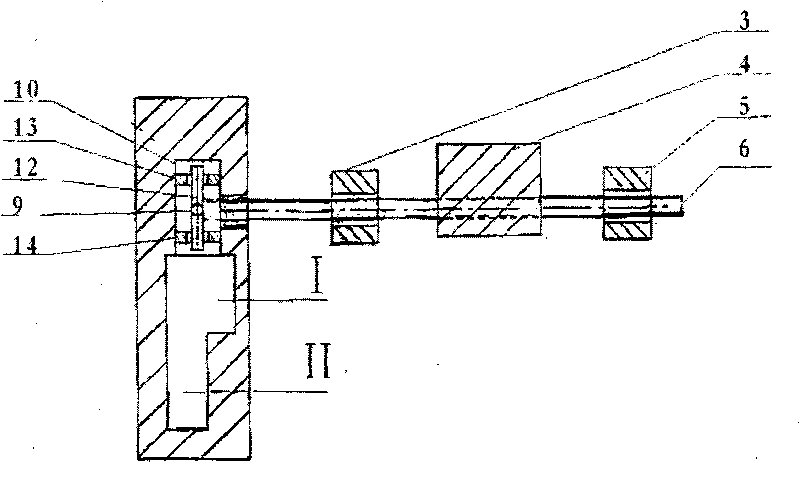

[0012] Example 1, see figure 1 , 2 , 3, at first process and make water storage tank (18), support (16), telescopic tube (19), the corresponding sealing of drainpipe (21) and the outlet (20) on the water storage pipe (18) is fixed, telescopic tube (19 ) lower port and the upper port of the drainpipe (21) are sealed and fixed, then the bracket (16) is fixedly installed on the tank wall of the water storage tank (18), and the sliding sleeve (8), axle seat (3 )(5), fix the upper counterweight (4) and the plate (15) on the shaft (6), fix the driving lever (2) on the counterweight (4), and then fix the driving lever (2) on the upper side belt The container (25) with drainage joints, the fixed position of the container with drainage joints on the side and the driving lever (2) should be determined according to the amount of flushing water required, and the balance time of the counterweight body (4) and the driving lever (2) should be determined. The shaft (6) is connected with the...

Embodiment 2

[0013] Embodiment 2, with embodiment 1, on the position of operating lever (9) on cabinet (1), process and make path I and path II, the upper surface of path I, II is arc-shaped, is conducive to observation and attractive in appearance like this. Water storage tank (18) can be installed on the cabinet frame of washbasin, and is corresponding with the outlet of washbasin, and will be close to the outlet of washbasin above, when washbasin cabinet was far away from closet, water storage tank ( 18) separately establish cabinet and install nearby, and be connected with the water tank below the washbasin with pipe, and the flushing port of drainpipe (21) other end introduces closet and is sealed and fixed.

[0014] According to the toilet flushing mechanism of the present invention, when in use, first, according to the amount of flushing water, one side force shaft (12) is used to rotate slightly, and the operating rod (9) touches the limit frame (10) and is pulled forward for operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com