Shaver head

A razor and cutter head technology, applied in metal processing and other directions, can solve the problems of rising manufacturing cost, uneven force, affecting shaving effect, etc., and achieve the effect of low requirements, lower cost, and improved shaving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

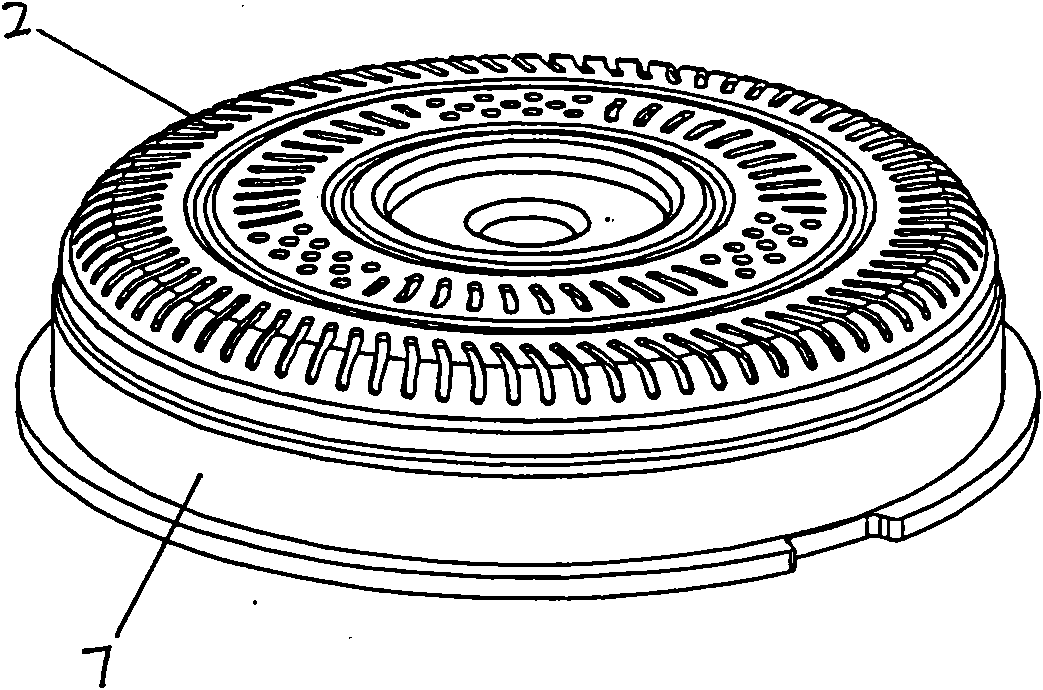

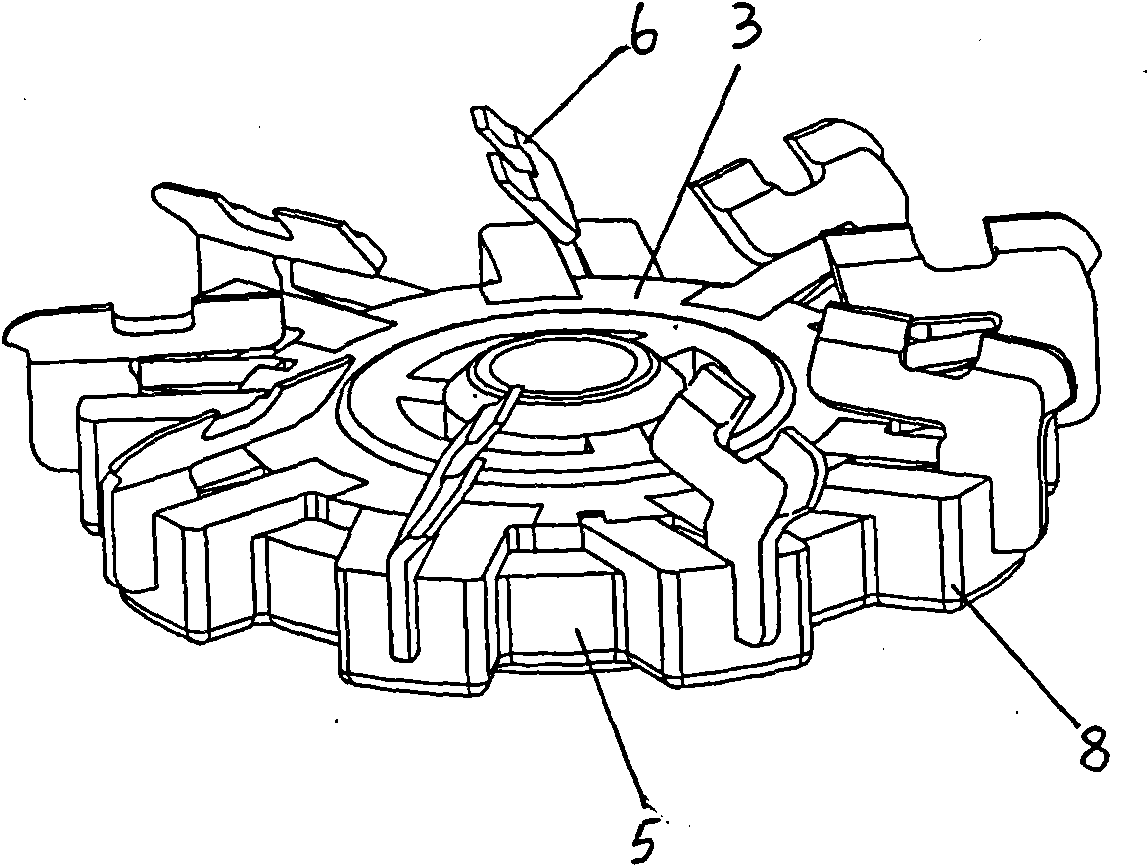

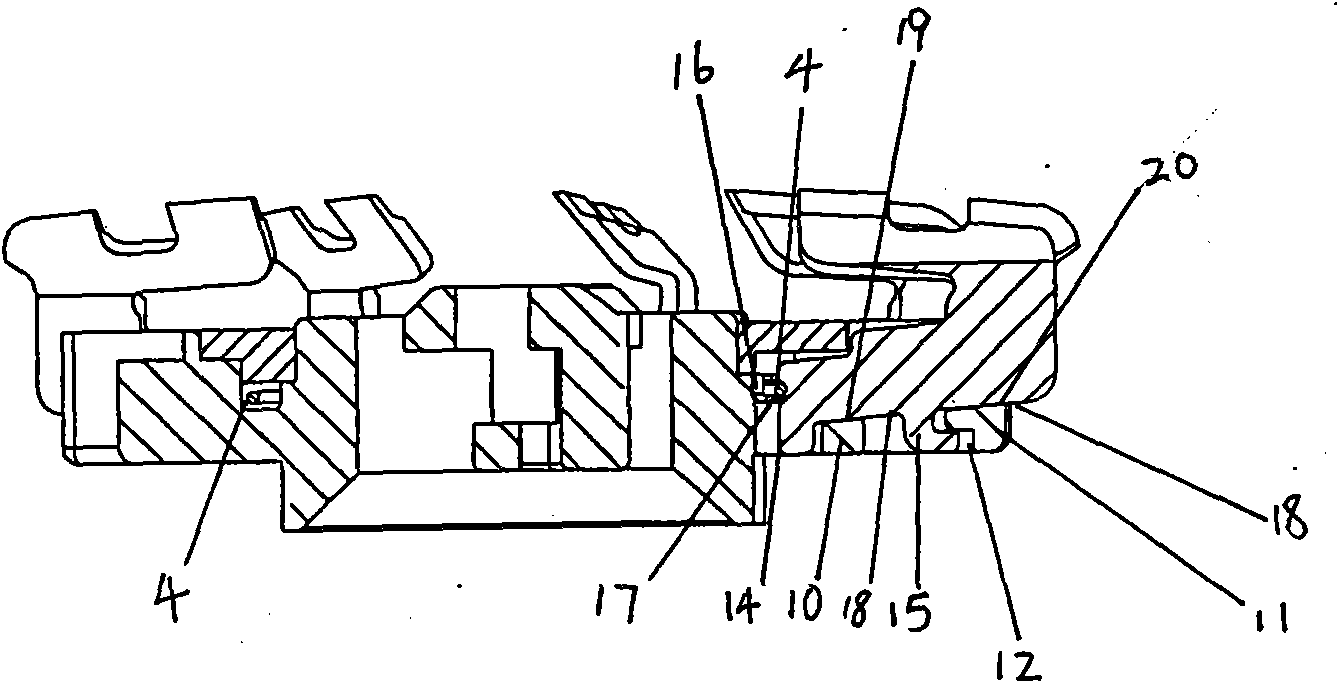

[0010] refer to figure 1 , figure 2 , image 3 , Figure 4 As shown, the first embodiment of the razor head provided by the present invention comprises a ring body 7, a plastic blade frame 5 and a net cover 2, the plastic blade frame 5 is provided with a blade 6, and the plastic blade frame 5 is arranged on the ring In the space formed by the body 7 and the net cover 2, the blade plastic frame 5 has a circularly distributed blade mounting seat 8, and the blade mounting seat 8 is provided with a mounting groove 9, and the mounting groove 9 has an upward and outward outlet. The inner bottom of the installation groove 9 is provided with a first block 10, the outer side of the bottom of the installation groove 9 is provided with a second block 11, the second block 11 is provided with a locking groove 12 inwardly, and the middle part of the blade 6 has an inner recess 13, The inner side of the lower end of the blade 6 has a first locking foot 14, and the middle part of the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com