Weaving method of high density panne velvet

A technology of weaving and velveteen, applied in the field of velveteen with high warp and weft density, and the field of weaving of high-density velveteen, can solve the problems of inability to produce high-density velveteen and the unsatisfactory requirements of heavy velveteen, achieve stable quality, improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 160×72 high-density chemical fiber velveteen

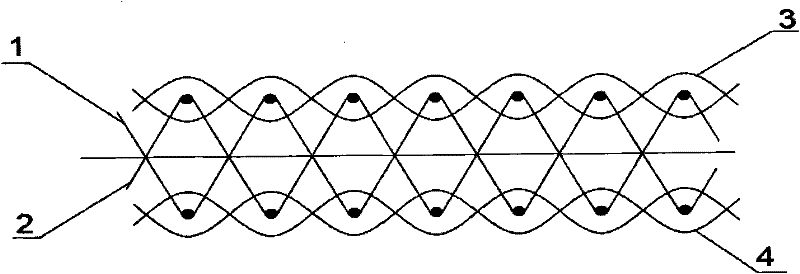

[0036] The structure of 160×72 high-density chemical fiber velveteen is as follows figure 1 As shown, the ground weave is plain weave, the pile fabric is V-shaped structure pile, and the ratio of ground warp to pile warp is 1:1.

[0037] The weaving method of 160×72 high-density chemical fiber velveteen is as follows:

[0038] (1). The finished warp density of 160×72 high-density chemical fiber velveteen is 160 threads / inch, the weft density is about 72 threads / inch, and the pile warp is semi-raised V-shaped structure pile.

[0039] The raw material of the ground warp is 150d (denier) polyester fiber filament, and the twist is 800t (twist) / m;

[0040] The raw material of the weft is 150d (denier) polyester fiber filament, and the twist is 600t (twist) / m;

[0041] The cashmere raw material is 150d (denier) polyester fiber filament, which adopts network yarn.

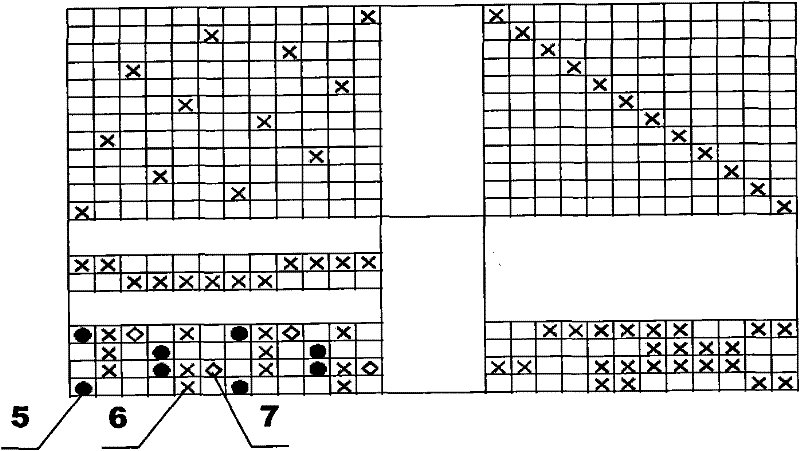

[0042] (2). Process parameters on the machine, such as figu...

Embodiment 2

[0052] 165×70 high-density chemical fiber velveteen, such as figure 1 As shown, the ground weave is plain weave, the pile fabric is V-shaped structure pile, and the ratio of ground warp to pile warp is 1:1.

[0053] The weaving method of 165 * 70 high-density chemical fiber velveteen is the same as embodiment 1, as follows:

[0054] (1). The finished warp density of 165×70 high-density chemical fiber velveteen is 165 threads / inch, the weft density is about 70 threads / inch, and the pile warp is half-raised V-shaped structure pile.

[0055] The raw material of the ground warp is 150d (denier) polyester fiber filament with a twist of 800t / m;

[0056] The raw material of the weft is 150d (denier) polyester fiber filament with a twist of 600t / m;

[0057] The cashmere raw material is 250d (denier) polyester fiber filament, which adopts network yarn.

[0058] (2). Process parameters on the machine, and figure 2 There are differences, but with figure 2 Similar to:

[0059] a. ...

Embodiment 3

[0068] 170×68 high-density chemical fiber velveteen,

[0069] The structure of 170×68 high-density chemical fiber velveteen is as follows figure 1 As shown, the ground weave is plain weave, the pile fabric is V-shaped structure pile, and the ratio of ground warp to pile warp is 1:1.

[0070] The weaving method of 170×68 high-density chemical fiber velveteen is as follows:

[0071] (1). The finished warp density of 170×68 high-density chemical fiber velveteen is 170 threads / inch, the weft density is about 68 threads / inch, and the pile warp is half-raised V-shaped structure pile.

[0072] The raw material of the ground warp is 150d (denier) polyester fiber network yarn;

[0073] The raw material of the weft is 150d (denier) polyester fiber network silk;

[0074] The cashmere raw material is 150d (denier) polyester fiber network yarn.

[0075] (2). Machine process parameters: such as figure 2 as shown,

[0076] a. Heald frame: same as embodiment 1, no more details.

[007...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com